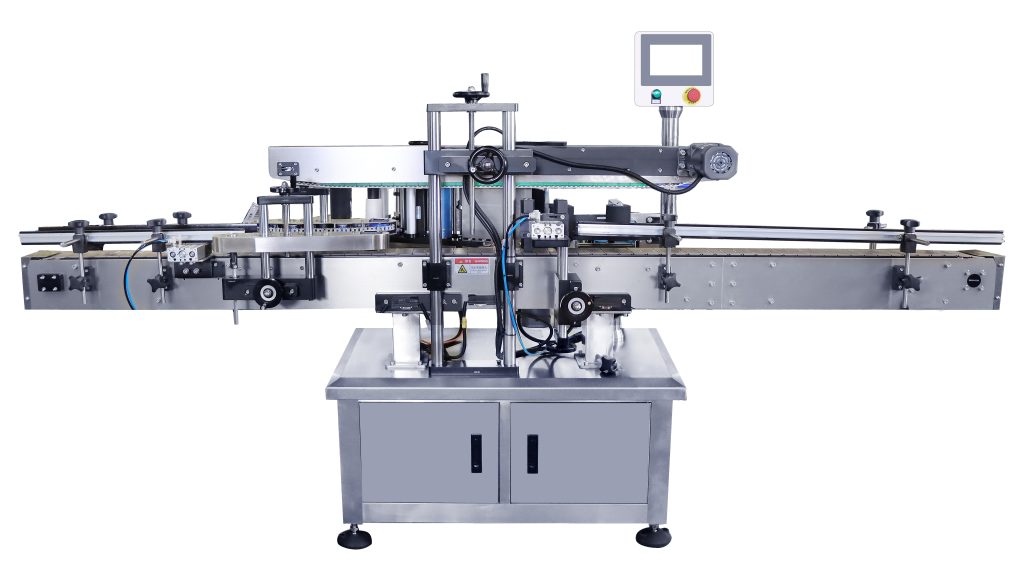

Double Side Pressure Sensitive Labeling Machine

This machine is designed for can label. Have functions of automatic stop, counting, power saving. Suitable for bottles, beer cans, and other cylindrical containers.Ideal for almost any industries labeling a wide range of products.

Main Features:

1. Can be produced in a single machine, or can be connected to the production line.

2. The equipment is made of stainless steel and wear-resistant aluminum alloy, in line with GMP production specifications, the overall structure is firm and beautiful.

3. One machine can realize single-side labeling machine for four products, round bottle, flat bottle, square bottle and shaped bottle.

4. The automatic splitting structure is configured, and the spacing is automatically separated before the guiding bottle to ensure the stability of subsequent guiding, conveying and labeling.

5. Intelligent control, automatic photoelectric tracking, with no object and no labeling, no label automatic calibration and automatic label detection.

6. Configure the double-overlaying structure to ensure the labeling accuracy and the second elastic-type overlay for the first time, effectively eliminating bubbles and ensuring that the label head and tail are tightly attached.

Main parameters:

1. Labeling speed: 0-180 bottles / minute (speed is related to diameter)

2. Diameter 30-150mm; height 30-350mm

3. Labeling accuracy : ±1mm

4. Compatible diameter range: diameter 25-150mm (customized according to customer requirements)

5. Height of conveyor belt from the ground: 800mm (can be customized according to customer requirements)

6. Voltage: 220V 50/60Hz

7. Air pressure: 5kg/cm³

8. Compatible label size: length 10-300 width 10-150 (customizable)

9. Equipment size: L2200*W800*H1580mm

10. Mechanical weight: about 200kg