Table of Contents

Benefits of Using an Auto Powder Auger Filling Machine

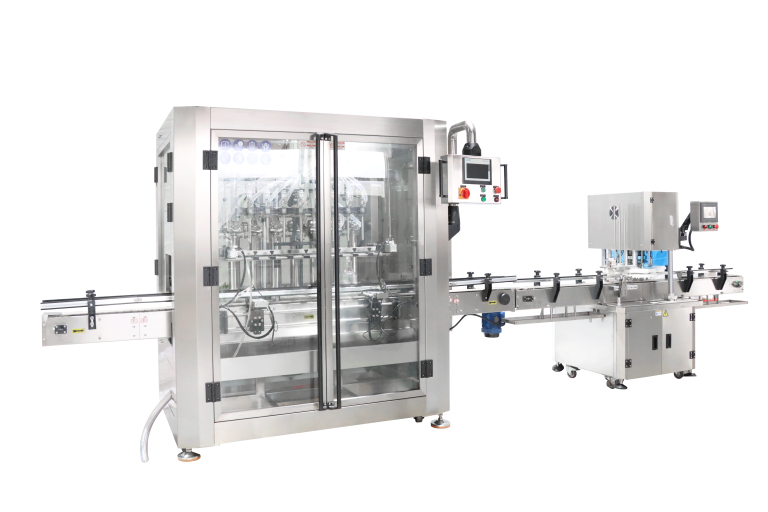

An auto powder auger filling machine is a versatile and efficient tool that can streamline the packaging process for a wide range of powdered products. From spices and seasonings to pharmaceuticals and cosmetics, this machine offers numerous benefits that can help businesses improve their productivity and efficiency.

One of the key benefits of using an auto powder auger filling machine is its accuracy. These machines are equipped with precision auger fillers that can accurately measure and dispense the exact amount of powder needed for each package. This ensures that every product is consistently filled to the correct weight, reducing waste and ensuring product quality.

In addition to accuracy, auto powder auger filling machines are also incredibly fast. These machines can fill hundreds of containers per minute, making them ideal for high-volume production environments. This increased speed can help businesses meet tight deadlines and keep up with customer demand, ultimately improving overall efficiency and profitability.

Another benefit of using an auto powder auger filling machine is its versatility. These machines can handle a wide range of powdered products, from fine powders to granular materials. This flexibility makes them suitable for a variety of industries, including food and beverage, pharmaceuticals, and cosmetics.

Furthermore, auto powder auger filling machines are easy to operate and maintain. Most machines come with user-friendly interfaces that allow operators to quickly set up and adjust filling parameters. Additionally, these machines are designed for easy cleaning and maintenance, reducing downtime and ensuring consistent performance.

Using an auto powder auger filling machine can also help businesses improve their packaging consistency. These machines can be programmed to fill each container with the same amount of powder, ensuring that every product meets the same quality standards. This consistency can help businesses build a strong brand reputation and increase customer loyalty.

Overall, an auto powder auger filling machine offers numerous benefits that can help businesses improve their productivity, efficiency, and product quality. From accuracy and speed to versatility and ease of use, these machines are a valuable asset for any packaging operation. By investing in an auto powder auger filling machine, businesses can streamline their packaging process and achieve greater success in today’s competitive market.

Step-by-Step Guide on How to Operate an Auto Powder Auger Filling Machine

An auto powder auger filling machine is a versatile and efficient tool used in various industries for filling containers with powdered products. Whether you are in the food, pharmaceutical, or cosmetic industry, this machine can help streamline your production process and ensure accurate and consistent filling. In this article, we will provide you with a step-by-step guide on how to operate an auto powder auger filling machine effectively.

First and foremost, it is essential to familiarize yourself with the different components of the machine. The main parts of an auto powder auger filling machine include the hopper, auger, filling head, and control panel. The hopper is where the powdered product is stored, while the auger is responsible for dispensing the product into the containers. The filling head is where the containers are placed for filling, and the control panel allows you to adjust settings such as fill volume and speed.

Before operating the machine, ensure that it is properly set up and calibrated. This includes adjusting the height of the filling head to accommodate different container sizes and calibrating the auger to dispense the correct amount of product. It is also important to check that the machine is clean and free of any debris that could affect the filling process.

Once the machine is set up, you can begin the filling process. Start by turning on the machine and setting the desired fill volume on the control panel. Place the containers under the filling head, making sure they are properly aligned for accurate filling. Press the start button to activate the auger, which will dispense the powdered product into the containers.

As the containers are being filled, monitor the process to ensure that the fill volume is consistent and accurate. You may need to make adjustments to the settings on the control panel if necessary. It is also important to keep an eye on the hopper and refill it as needed to prevent any interruptions in the filling process.

Once all the containers have been filled, turn off the machine and clean it thoroughly to prevent any product buildup or contamination. This includes removing any leftover product from the hopper, auger, and filling head, as well as wiping down the machine with a clean cloth.

In conclusion, operating an auto powder auger filling machine is a straightforward process that can greatly improve the efficiency and accuracy of your production line. By following the steps outlined in this guide, you can ensure that your machine operates smoothly and delivers consistent results every time. Remember to regularly maintain and clean the machine to prolong its lifespan and prevent any issues during operation. With proper care and attention, an auto powder auger filling machine can be a valuable asset to your business.

Common Issues and Troubleshooting Tips for Auto Powder Auger Filling Machines

Auto powder auger filling machines are a popular choice for packaging powdered products efficiently and accurately. However, like any piece of machinery, these machines can encounter issues that may affect their performance. In this article, we will discuss some common issues that may arise when using an auto powder auger filling machine and provide troubleshooting tips to help you resolve them.

One common issue that users may encounter with auto powder auger filling machines is inconsistent filling. This can result in variations in the amount of product dispensed into each container, leading to inaccurate packaging. Inconsistent filling can be caused by a number of factors, including improper calibration of the machine, worn or damaged parts, or incorrect settings.

To troubleshoot this issue, start by checking the calibration of the machine. Make sure that the machine is set to dispense the correct amount of product for each container size. If the calibration is correct, inspect the auger and other components for any signs of wear or damage. Replace any worn parts to ensure smooth and consistent operation. Additionally, double-check the settings on the machine to ensure that they are optimized for the type of product being filled.

Another common issue with auto powder auger filling machines is clogging. Clogging can occur when the powder being dispensed becomes compacted or stuck in the auger or other components of the machine. This can result in downtime and decreased productivity.

To address clogging issues, start by checking the consistency of the powder being used. If the powder is too fine or too clumpy, it may be more prone to clogging. Adjusting the speed of the auger or using a different type of powder may help alleviate this issue. Additionally, regularly cleaning and maintaining the machine can help prevent clogs from occurring. Make sure to follow the manufacturer’s guidelines for cleaning and maintenance to keep your machine running smoothly.

One more common issue that users may encounter with auto powder auger filling machines is leaking. Leaking can occur when the product spills or drips from the machine during the filling process, leading to product waste and potential contamination. Leaking can be caused by loose or damaged seals, improper alignment of components, or overfilling of containers.

To troubleshoot leaking issues, start by inspecting the seals on the machine for any signs of wear or damage. Replace any damaged seals to prevent leaks from occurring. Additionally, check the alignment of the components of the machine to ensure that they are properly positioned. Overfilling containers can also lead to leaking, so make sure that the machine is set to dispense the correct amount of product for each container size.

In conclusion, auto powder auger filling machines are a valuable tool for packaging powdered products efficiently and accurately. However, like any piece of machinery, these machines can encounter issues that may affect their performance. By being aware of common issues and following troubleshooting tips, you can keep your auto powder auger filling machine running smoothly and maximize its productivity.