Table of Contents

Benefits of Using a Weigher Cashew Nut Filling Sealing and Screw Capping Line

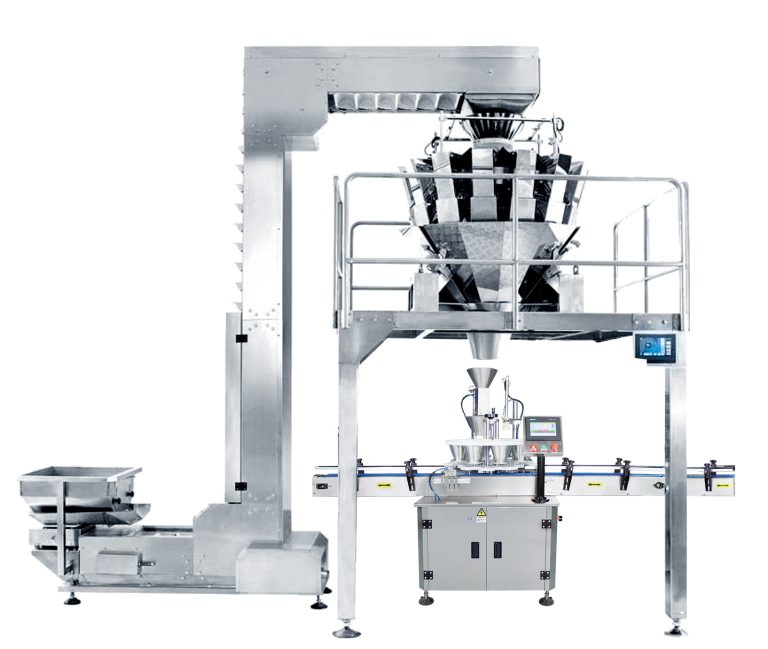

In the food packaging industry, efficiency and accuracy are key factors in ensuring the quality of products and meeting consumer demands. One of the most important processes in food packaging is filling, sealing, and capping, which can be a time-consuming and labor-intensive task if done manually. This is where a weigher cashew nut filling sealing and screw capping line comes in handy, offering numerous benefits for manufacturers looking to streamline their production process.

One of the main advantages of using a weigher cashew nut filling sealing and screw capping line is the increased efficiency it provides. By automating the filling, sealing, and capping process, manufacturers can significantly reduce the time and labor required to package their products. This not only allows for higher production volumes but also ensures a consistent and accurate fill weight for each package, improving overall product quality.

Additionally, a weigher cashew nut filling sealing and screw capping line can help reduce the risk of product contamination. Manual filling and sealing processes can be prone to errors, leading to inconsistencies in product weight and potential contamination from improper sealing. By using an automated filling and sealing line, manufacturers can minimize the risk of contamination and ensure that each package is properly sealed and protected.

Another benefit of using a weigher cashew nut filling sealing and screw capping line is the cost savings it can provide. While the initial investment in an automated packaging line may be higher than manual processes, the long-term cost savings can be significant. By reducing labor costs, improving efficiency, and minimizing product waste, manufacturers can see a return on their investment in a relatively short amount of time.

Furthermore, a weigher cashew nut filling sealing and screw capping line can help improve overall product quality and consistency. By automating the filling and sealing process, manufacturers can ensure that each package is filled to the correct weight and sealed properly, reducing the risk of product recalls and customer complaints. This level of consistency can help build consumer trust and loyalty, ultimately leading to increased sales and brand reputation.

In conclusion, the benefits of using a weigher cashew nut filling sealing and screw capping line are clear. From increased efficiency and cost savings to improved product quality and consistency, automated packaging lines offer numerous advantages for manufacturers in the food packaging industry. By investing in a weigher cashew nut filling sealing and screw capping line, manufacturers can streamline their production process, reduce the risk of contamination, and ultimately improve their bottom line.

How to Optimize Efficiency in Your Cashew Nut Packaging Process

In the world of food packaging, efficiency is key. Whether you are a small-scale producer or a large-scale manufacturer, optimizing your packaging process can lead to cost savings, increased productivity, and ultimately, higher profits. One area where efficiency can make a big difference is in the packaging of cashew nuts.

Cashew nuts are a popular snack enjoyed by people all over the world. They are not only delicious but also packed with nutrients, making them a healthy choice for consumers. As a producer of cashew nuts, it is important to ensure that your packaging process is efficient and effective in order to meet the demands of the market.

One way to optimize efficiency in your cashew nut packaging process is to invest in a weigher cashew nut filling sealing and screw capping line. This type of packaging line is designed to automate the process of weighing, filling, sealing, and capping cashew nuts in containers, such as jars or bags. By using a weigher cashew nut filling sealing and screw capping line, you can significantly reduce the time and labor required to package your products, while also improving the accuracy and consistency of your packaging.

One of the key benefits of using a weigher cashew nut filling sealing and screw capping line is that it can help you increase the speed of your packaging process. With automated weighing and filling systems, you can quickly and accurately fill containers with the precise amount of cashew nuts, reducing the risk of underfilling or overfilling. This can help you meet the demands of your customers and ensure that your products are consistently packaged to the highest standards.

In addition to speed, a weigher cashew nut filling sealing and screw capping line can also help you improve the quality of your packaging. By automating the sealing and capping process, you can ensure that your products are securely sealed and protected from contamination. This can help you maintain the freshness and quality of your cashew nuts, ensuring that they reach consumers in perfect condition.

Furthermore, using a weigher cashew nut filling sealing and screw capping line can help you reduce waste and minimize product loss. By accurately weighing and filling containers, you can avoid overfilling and reduce the amount of product that is wasted during the packaging process. This can help you save money on raw materials and improve the overall efficiency of your operation.

Overall, investing in a weigher cashew nut filling sealing and screw capping line can help you optimize efficiency in your cashew nut packaging process. By increasing speed, improving quality, and reducing waste, you can streamline your operation and meet the demands of the market. Whether you are a small-scale producer or a large-scale manufacturer, a weigher cashew nut filling sealing and screw capping line can help you take your packaging process to the next level.

Common Challenges and Solutions for Weigher Cashew Nut Filling Sealing and Screw Capping Lines

Weigher cashew nut filling sealing and screw capping lines are essential components in the food packaging industry. These lines are used to accurately fill containers with cashew nuts, seal them to ensure freshness, and screw on caps to prevent spillage. However, like any other machinery, weigher cashew nut filling sealing and screw capping lines come with their own set of challenges. In this article, we will discuss some common challenges faced by operators of these lines and provide solutions to overcome them.

One of the most common challenges faced by operators of weigher cashew nut filling sealing and screw capping lines is inconsistent filling. This can lead to underfilled or overfilled containers, which can affect the quality of the product and lead to customer dissatisfaction. To overcome this challenge, operators should regularly calibrate the weigher to ensure accurate measurements. They should also check for any blockages or obstructions in the filling tubes that may be causing the inconsistency.

Another challenge faced by operators is sealing issues. If the sealing process is not done correctly, it can lead to leaks and spoilage of the cashew nuts. To prevent this, operators should regularly check the sealing equipment for wear and tear and replace any damaged parts. They should also ensure that the sealing temperature and pressure are set correctly to create a tight seal.

Screw capping can also pose a challenge for operators of these lines. If the caps are not screwed on tightly enough, they can come loose during transportation and storage, leading to spillage. To overcome this challenge, operators should regularly check the capping equipment for any malfunctions and adjust the torque settings to ensure a secure fit. They should also inspect the caps for any defects that may prevent them from screwing on properly.

In addition to these challenges, operators of weigher cashew nut filling sealing and screw capping lines may also face issues with maintenance and downtime. Regular maintenance is essential to keep the lines running smoothly and prevent breakdowns. Operators should follow the manufacturer’s guidelines for maintenance and schedule regular inspections to identify any potential issues before they escalate. In the event of a breakdown, operators should have a contingency plan in place to minimize downtime and prevent delays in production.

Overall, operators of weigher cashew nut filling sealing and screw capping lines face a variety of challenges in their day-to-day operations. However, by implementing proper maintenance procedures, calibrating equipment regularly, and addressing issues as they arise, these challenges can be overcome. With a proactive approach and attention to detail, operators can ensure that their lines run efficiently and produce high-quality products for their customers.