Table of Contents

Benefits of Using Weigh Filling and Packing Machine for Chilli

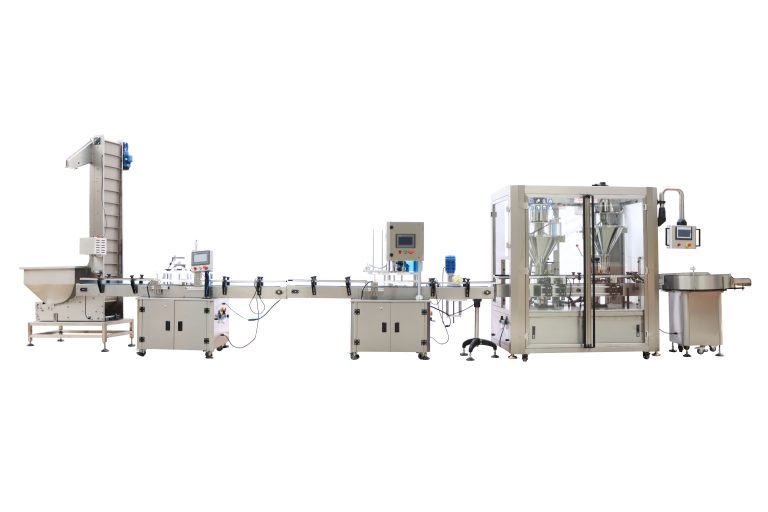

Weigh filling and packing machines have become an essential tool in the food industry, especially for products like chilli and soup. These machines offer numerous benefits that can help streamline the production process and improve overall efficiency. In this article, we will explore the advantages of using weigh filling and packing machines for chilli and soup products.

One of the primary benefits of using a weigh filling and packing machine is accuracy. These machines are designed to precisely measure and dispense the correct amount of product into each package. This ensures that every package contains the same amount of product, reducing waste and ensuring consistency in the final product. With weigh filling machines, you can be confident that your customers are getting the exact amount of chilli or soup they expect in every package.

In addition to accuracy, weigh filling and packing machines also offer speed and efficiency. These machines are capable of filling and packing products at a much faster rate than manual methods. This can help increase production output and reduce labor costs. With a weigh filling machine, you can pack more products in less time, allowing you to meet customer demand more efficiently.

Another benefit of using a weigh filling and packing machine for chilli and soup products is versatility. These machines can be easily adjusted to accommodate different package sizes and product weights. This flexibility allows you to easily switch between different products or package sizes without the need for extensive retooling or downtime. Whether you are packaging small individual servings of chilli or large family-sized containers of soup, a weigh filling machine can handle the job with ease.

Furthermore, weigh filling and packing machines are also hygienic and sanitary. These machines are designed to meet strict food safety standards and are easy to clean and maintain. This helps prevent contamination and ensures that your products are safe for consumption. By using a weigh filling machine, you can rest assured that your chilli and soup products are being packed in a clean and sanitary environment.

Additionally, weigh filling and packing machines can also help reduce product loss and waste. These machines are designed to minimize product spillage and ensure that every last bit of product is dispensed into the package. This can help reduce costs and improve overall profitability. With a weigh filling machine, you can maximize your product yield and minimize waste, ultimately saving you money in the long run.

In conclusion, weigh filling and packing machines offer numerous benefits for packaging chilli and soup products. From accuracy and efficiency to versatility and hygiene, these machines can help streamline the production process and improve overall product quality. If you are looking to improve your packaging process for chilli and soup products, consider investing in a weigh filling and packing machine. Your customers and your bottom line will thank you.

How to Choose the Right Weigh Filling and Packing Machine for Soup

When it comes to packaging soup and chilli, choosing the right weigh filling and packing machine is crucial. These machines are designed to accurately measure and fill products into containers, ensuring consistency and efficiency in the packaging process. With a wide range of options available on the market, it can be overwhelming to select the best machine for your specific needs. In this article, we will discuss some key factors to consider when choosing a weigh filling and packing machine for soup and chilli.

One of the most important considerations when selecting a weigh filling and packing machine is the type of product you will be packaging. Soup and chilli are viscous liquids that require a machine capable of handling their unique properties. Look for a machine that is specifically designed for liquid products, with features such as drip-free filling nozzles and adjustable fill speeds to accommodate different viscosities.

Another important factor to consider is the production volume of your operation. If you have a high-volume production facility, you will need a machine that can keep up with the demand. Look for a weigh filling and packing machine with a high-speed filling capacity and the ability to handle large batch sizes. On the other hand, if you have a smaller operation, a compact machine with lower throughput may be more suitable.

Accuracy is another critical factor to consider when choosing a weigh filling and packing machine for soup and chilli. The machine should be able to accurately measure and dispense the desired amount of product into each container, ensuring consistency in portion sizes. Look for a machine with precision weighing technology and adjustable filling parameters to achieve the desired level of accuracy.

Ease of use and maintenance are also important considerations when selecting a weigh filling and packing machine. The machine should be user-friendly, with intuitive controls and easy-to-clean components. Look for a machine that is easy to set up and adjust for different products and batch sizes. Additionally, consider the maintenance requirements of the machine, such as regular cleaning and calibration procedures, to ensure optimal performance and longevity.

Cost is another factor to consider when choosing a weigh filling and packing machine for soup and chilli. While it is important to invest in a high-quality machine that meets your production needs, it is also essential to consider your budget constraints. Compare the prices and features of different machines to find the best value for your money. Keep in mind that a higher upfront cost may be justified by increased efficiency and productivity in the long run.

In conclusion, selecting the right weigh filling and packing machine for soup and chilli requires careful consideration of factors such as product type, production volume, accuracy, ease of use, maintenance, and cost. By evaluating these factors and choosing a machine that meets your specific needs, you can ensure efficient and consistent packaging of your products. Take the time to research and compare different machines to find the best fit for your operation. With the right weigh filling and packing machine, you can streamline your packaging process and deliver high-quality products to your customers.