Table of Contents

Benefits of Using Vacuum Nitrogen Flushing Machine for Milk Powder Packaging

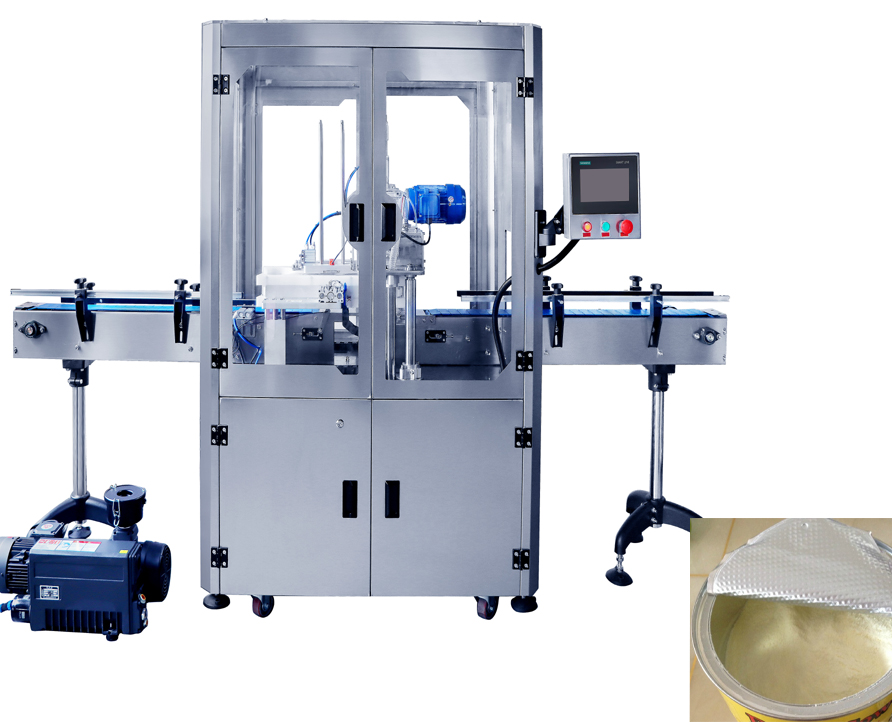

Vacuum nitrogen flushing machines have become an essential tool in the food packaging industry, especially for products like milk powder. These machines are designed to remove oxygen from the packaging and replace it with nitrogen, creating a controlled atmosphere that helps to preserve the freshness and quality of the product. In this article, we will explore the benefits of using a vacuum nitrogen flushing machine for milk powder packaging.

One of the primary benefits of using a vacuum nitrogen flushing machine is the extended shelf life it provides for milk powder. Oxygen is a major contributor to the degradation of food products, as it can lead to oxidation and the growth of harmful bacteria. By removing oxygen from the packaging and replacing it with nitrogen, the vacuum nitrogen flushing machine helps to create a barrier that protects the milk powder from these damaging effects. This, in turn, helps to extend the shelf life of the product, ensuring that it remains fresh and safe for consumption for a longer period of time.

In addition to extending the shelf life of milk powder, vacuum nitrogen flushing machines also help to maintain the quality of the product. Oxygen can cause milk powder to lose its flavor, aroma, and nutritional value over time. By creating a controlled atmosphere with nitrogen, the vacuum nitrogen flushing machine helps to preserve the quality of the milk powder, ensuring that it retains its taste, aroma, and nutritional content for a longer period of time. This is particularly important for consumers who expect high-quality products that meet their expectations for taste and nutrition.

Furthermore, vacuum nitrogen flushing machines help to improve the overall appearance of milk powder packaging. Oxygen can cause milk powder to become discolored and develop off-flavors, which can be unappealing to consumers. By removing oxygen from the packaging, the vacuum nitrogen flushing machine helps to maintain the color, flavor, and overall appearance of the milk powder, ensuring that it looks and tastes as fresh as possible. This can help to enhance the appeal of the product to consumers, leading to increased sales and customer satisfaction.

Another benefit of using a vacuum nitrogen flushing machine for milk powder packaging is the reduction of food waste. By extending the shelf life of milk powder and maintaining its quality, vacuum nitrogen flushing machines help to reduce the amount of product that is wasted due to spoilage or degradation. This not only benefits manufacturers by reducing costs associated with wasted product but also benefits consumers by ensuring that they are able to enjoy fresh and high-quality milk powder for a longer period of time.

In conclusion, vacuum nitrogen flushing machines offer a range of benefits for milk powder packaging. From extending the shelf life and maintaining the quality of the product to improving its appearance and reducing food waste, these machines play a crucial role in ensuring that milk powder remains fresh, safe, and appealing to consumers. As the food packaging industry continues to evolve, vacuum nitrogen flushing machines will likely become even more essential for preserving the quality and safety of food products like milk powder.

How to Choose the Right Vacuum Nitrogen Flushing Machine for Milk Powder Production

In the production of milk powder, ensuring the quality and shelf life of the product is crucial. One way to achieve this is through the use of a vacuum nitrogen flushing machine. This machine helps to remove oxygen from the packaging, which can cause oxidation and spoilage of the milk powder. By replacing the oxygen with nitrogen, the product is protected from degradation and maintains its freshness for a longer period of time.

When choosing a vacuum nitrogen flushing machine for milk powder production, there are several factors to consider. The first is the capacity of the machine. It is important to select a machine that can handle the volume of milk powder that needs to be packaged. This will ensure that production runs smoothly and efficiently.

Another important factor to consider is the level of automation of the machine. Some machines are fully automated, while others require more manual intervention. Depending on the size of the production facility and the level of expertise of the operators, a more automated machine may be preferred to ensure consistency and accuracy in the packaging process.

The type of packaging material used is also an important consideration when choosing a vacuum nitrogen flushing machine. Different materials have different properties, and the machine must be compatible with the specific material being used. It is important to ensure that the machine can effectively remove oxygen from the packaging material and replace it with nitrogen without compromising the integrity of the packaging.

In addition to these factors, it is important to consider the overall efficiency and reliability of the machine. Look for a machine that is easy to operate and maintain, with a track record of reliability and durability. This will help to minimize downtime and ensure that production runs smoothly without any interruptions.

When selecting a vacuum nitrogen flushing machine, it is also important to consider the cost of the machine and the return on investment. While it may be tempting to opt for a cheaper machine, it is important to consider the long-term benefits of investing in a higher quality machine that will deliver consistent results and protect the quality of the milk powder.

In conclusion, choosing the right vacuum nitrogen flushing machine for milk powder production is essential to ensure the quality and shelf life of the product. Consider factors such as capacity, automation, packaging material compatibility, efficiency, reliability, and cost when making your decision. By selecting a machine that meets these criteria, you can ensure that your milk powder is packaged safely and efficiently, maintaining its freshness and quality for consumers to enjoy.