Table of Contents

Benefits of Using Vacuum Capping Machine for Preserving Jam in Glass Bottles

Preserving jam in glass bottles is a common practice for many households and businesses. However, ensuring that the jam stays fresh and free from contamination can be a challenge. This is where a vacuum capping machine comes in handy.

A vacuum capping machine is a device that helps seal glass bottles by removing air from the container before sealing it with a cap. This process creates a vacuum inside the bottle, which helps preserve the jam for a longer period. There are several benefits to using a vacuum capping machine for preserving jam in glass bottles.

One of the main benefits of using a vacuum capping machine is that it helps extend the shelf life of the jam. By removing air from the bottle, the machine helps prevent oxidation and microbial growth, which can cause the jam to spoil. This means that the jam can stay fresh and flavorful for a longer period, reducing waste and saving money in the long run.

Another benefit of using a vacuum capping machine is that it helps maintain the quality of the jam. Air can cause the jam to lose its color, flavor, and texture over time. By removing air from the bottle, the machine helps preserve the jam’s quality, ensuring that it tastes just as good as the day it was made.

In addition to extending the shelf life and maintaining the quality of the jam, a vacuum capping machine also helps improve the overall presentation of the product. A properly sealed glass bottle not only looks more professional but also helps protect the jam from external contaminants. This can be especially important for businesses that sell their jam to customers, as a well-sealed bottle can help build trust and loyalty among consumers.

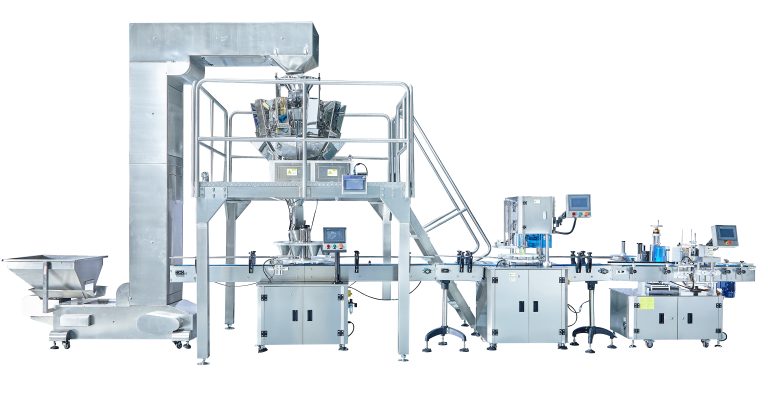

Furthermore, using a vacuum capping machine can help streamline the production process. Manual capping can be time-consuming and labor-intensive, especially for businesses that produce large quantities of jam. A vacuum capping machine can help automate the capping process, allowing for faster production and increased efficiency. This can help businesses save time and resources, ultimately leading to higher profits.

Overall, using a vacuum capping machine for preserving jam in glass bottles offers a wide range of benefits. From extending the shelf life and maintaining the quality of the jam to improving presentation and streamlining production, the machine can help businesses and households alike preserve their jam more effectively. Whether you are a small-scale producer or a large-scale manufacturer, investing in a vacuum capping machine can help you take your jam preservation to the next level.

Step-by-Step Guide on How to Properly Use a Vacuum Capping Machine for Jam Glass Bottles

Vacuum capping machines are essential tools for preserving the freshness and quality of food products, especially when it comes to jam glass bottles. These machines work by removing the air from the bottle before sealing it with a cap, creating a vacuum seal that helps to extend the shelf life of the product. In this article, we will provide a step-by-step guide on how to properly use a vacuum capping machine for jam glass bottles.

First and foremost, it is important to ensure that the vacuum capping machine is set up correctly before use. This includes making sure that the machine is clean and free of any debris that could potentially contaminate the product. Additionally, it is important to check that the machine is properly calibrated to ensure that it is sealing the bottles correctly.

Once the machine is set up, the next step is to prepare the jam glass bottles for sealing. This includes filling the bottles with the desired amount of jam and ensuring that the rims of the bottles are clean and free of any jam residue. It is also important to make sure that the caps are clean and free of any defects that could prevent a proper seal.

After the bottles are prepared, they can be placed on the conveyor belt of the vacuum capping machine. The machine will then automatically remove the air from the bottles and seal them with the caps. It is important to monitor the machine during this process to ensure that the bottles are being sealed correctly.

Once the bottles have been sealed, it is important to check the seals to ensure that they are tight and secure. This can be done by visually inspecting the caps to make sure that they are properly sealed. Additionally, it is a good idea to test the seals by gently pressing on the caps to ensure that they do not pop off.

After the bottles have been sealed and checked, they can be labeled and stored in a cool, dry place. It is important to store the bottles properly to ensure that the jam remains fresh and flavorful for as long as possible. Proper storage can help to extend the shelf life of the product and prevent spoilage.

In conclusion, vacuum capping machines are essential tools for preserving the freshness and quality of jam glass bottles. By following the steps outlined in this article, you can ensure that your jam products are properly sealed and preserved for maximum freshness. Proper use of a vacuum capping machine can help to extend the shelf life of your jam products and ensure that they remain delicious for as long as possible.