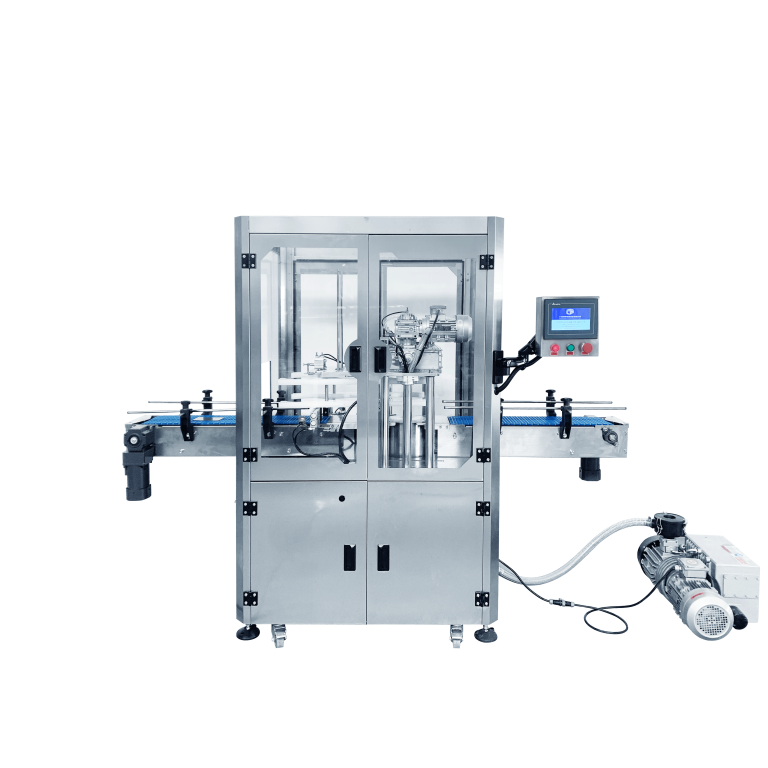

The Fully Automatic High-Speed Negative Pressure Vacuum Tin Can Sealing Machine represents a significant advancement in the field of can sealing. Let’s take a detailed look at its extraordinary features and the impact it has on the packaging industry.

This machine is ingeniously crafted to deliver a rapid and precise negative pressure vacuum sealing process for tin cans. Its fully automatic functionality ensures a seamless operation, maximizing production efficiency and minimizing human error.

The high-speed capability of this machine is a game-changer, allowing for a large number of tin cans to be sealed in a short period. This not only increases output but also meets the demands of high-volume production lines.

It is engineered to create a tight and reliable seal, protecting the contents from spoilage and external influences. The negative pressure vacuum feature enhances the preservation of the products inside the cans.

The machine’s adaptability enables it to handle various tin can sizes and shapes, providing flexibility for different packaging needs.

The durability and stability of its construction ensure long-term, trouble-free operation, making it a valuable asset for manufacturing facilities.

In conclusion, the Fully Automatic High-Speed Negative Pressure Vacuum Tin Can Sealing Machine is a revolutionary tool that sets new standards in can sealing.