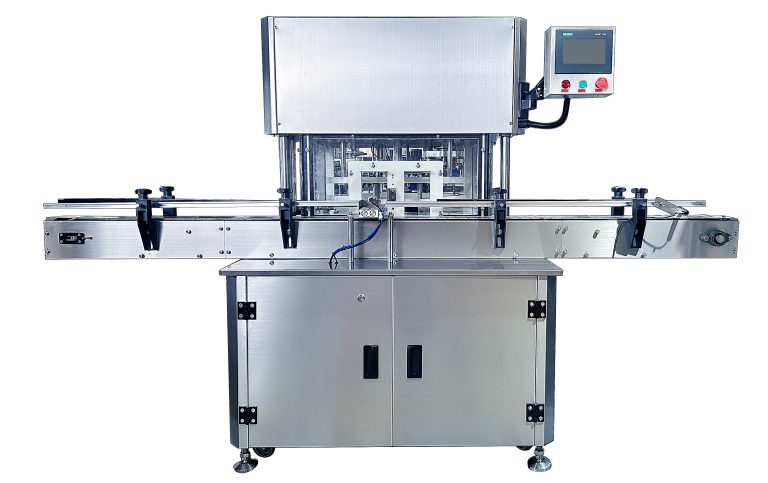

In the diverse world of packaging, the ability to handle a wide range of container types is a significant advantage. Dual-head servo machines have proven their mettle by effortlessly managing over 20 different container types, from cans to tins and beyond.

The secret behind their versatility lies in their advanced design and intelligent control systems. These machines are engineered with precision and flexibility, allowing them to adapt quickly to the unique characteristics of each container.

The dual-head configuration enables simultaneous processing, significantly increasing efficiency. Whether it’s the shape, size, or material of the container, the servo technology precisely adjusts the parameters to ensure a perfect seal or operation every time.

The machines’ software is programmed to recognize and accommodate the variations in container dimensions and properties. This means that operators can switch between different container types with minimal setup time and hassle.

The mechanical components of the dual-head servo machines are also designed for durability and adaptability. They can withstand the stresses and demands of handling various containers without compromising performance or reliability.

Whether it’s thin aluminum cans, thick steel tins, or containers with complex geometries, these machines have the capabilities to handle them all. Their ability to handle such a wide array of container types makes them an invaluable asset in industries where diverse packaging needs are the norm.

In conclusion, dual-head servo machines have redefined packaging flexibility by effortlessly managing more than 20 container types. Their combination of advanced technology, adaptability, and efficiency makes them a key player in the packaging landscape, meeting the ever-changing demands of the market.