Table of Contents

Benefits of Using Auger Powder Filling Machines in Production Lines

Auger powder filling machines have become an essential tool in various production lines across industries. These machines offer numerous benefits that help streamline the production process and improve efficiency. In this article, we will explore the advantages of using auger powder filling machines in production lines.

One of the key benefits of using auger powder filling machines is their accuracy. These machines are designed to dispense precise amounts of powder, ensuring consistency in product quality. This level of accuracy is crucial in industries where even a slight deviation in the amount of powder can affect the final product. By using auger powder filling machines, manufacturers can minimize waste and reduce the risk of errors in the production process.

In addition to accuracy, auger powder filling machines are also known for their speed. These machines can fill containers quickly and efficiently, allowing manufacturers to increase their production output. This is especially important in industries where high volumes of products need to be filled within a short period of time. By using auger powder filling machines, manufacturers can meet demand and maintain a competitive edge in the market.

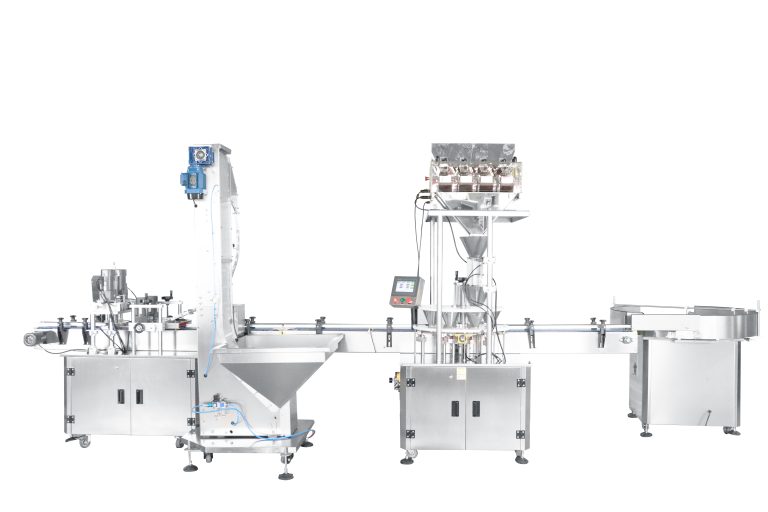

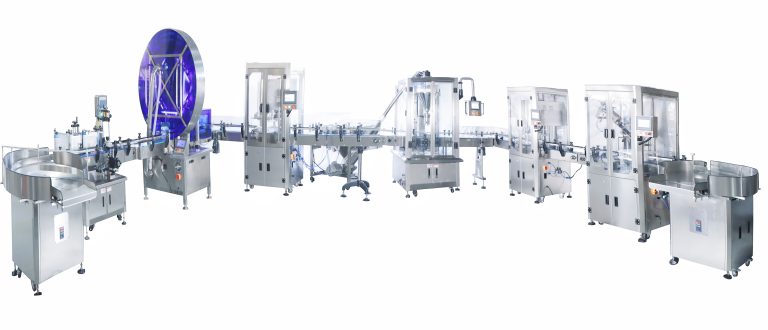

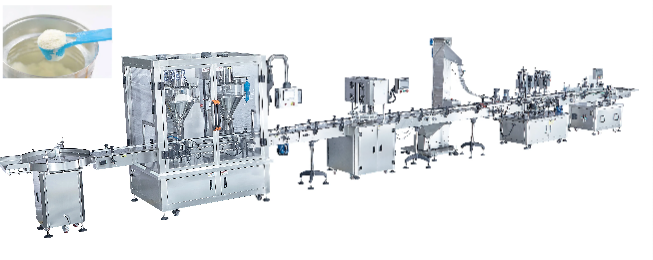

Another benefit of using auger powder filling machines is their versatility. These machines can handle a wide range of powders, from fine to coarse, without the need for extensive adjustments. This flexibility allows manufacturers to use the same machine for different products, saving time and resources. Additionally, auger powder filling machines can be easily integrated into existing production lines, making them a cost-effective solution for manufacturers looking to improve their operations.

Auger powder filling machines are also known for their reliability. These machines are built to withstand the rigors of continuous use, ensuring consistent performance over time. This reliability is essential in industries where downtime can result in significant losses. By using auger powder filling machines, manufacturers can minimize the risk of breakdowns and maintain a smooth production process.

Furthermore, auger powder filling machines are easy to operate and maintain. These machines are designed with user-friendly interfaces and intuitive controls, making them accessible to operators of all skill levels. Additionally, auger powder filling machines require minimal maintenance, reducing downtime and ensuring continuous operation. This ease of use and maintenance makes auger powder filling machines a practical choice for manufacturers looking to streamline their production process.

In conclusion, the use of auger powder filling machines in production lines offers numerous benefits, including accuracy, speed, versatility, reliability, and ease of operation. These machines have become an indispensable tool for manufacturers looking to improve efficiency and maintain product quality. By investing in auger powder filling machines, manufacturers can optimize their production process and stay ahead of the competition.

Tips for Optimizing Efficiency with Auger Powder Filling Machines

Auger powder filling machines are a crucial component in many production lines across various industries. These machines are designed to accurately dispense powdered substances into containers, ensuring consistency and efficiency in the manufacturing process. By understanding how to optimize the use of auger powder filling machines, companies can improve their production output and reduce waste.

One key tip for maximizing efficiency with auger powder filling machines is to calibrate the equipment regularly. Calibration ensures that the machine is dispensing the correct amount of powder into each container, preventing overfilling or underfilling. By regularly calibrating the machine, companies can maintain product quality and reduce the risk of costly errors in the production process.

Another important factor to consider when using auger powder filling machines is the type of powder being dispensed. Different powders have varying properties, such as density and flowability, which can affect how the machine operates. It is essential to adjust the settings on the machine to accommodate the specific characteristics of the powder being used, ensuring accurate and consistent filling.

In addition to calibration and powder type, proper maintenance of auger powder filling machines is crucial for optimizing efficiency. Regular cleaning and inspection of the machine can prevent clogs and malfunctions, ensuring smooth operation and minimizing downtime. By keeping the machine well-maintained, companies can avoid costly repairs and delays in production.

Furthermore, training employees on how to operate auger powder filling machines correctly is essential for maximizing efficiency. Proper training can help employees understand how to adjust settings, troubleshoot issues, and maintain the machine effectively. By investing in employee training, companies can ensure that their production line runs smoothly and efficiently.

Additionally, integrating auger powder filling machines with other automated systems in the production line can further enhance efficiency. By connecting the filling machine to conveyors, labeling machines, and other equipment, companies can streamline the manufacturing process and reduce manual labor. Automation can also improve accuracy and consistency in filling operations, leading to higher quality products and increased productivity.

Moreover, monitoring and analyzing data from auger powder filling machines can provide valuable insights into production efficiency. By tracking metrics such as fill weight, speed, and downtime, companies can identify areas for improvement and make informed decisions to optimize the manufacturing process. Data analysis can help companies identify trends, detect issues early, and implement strategies to enhance efficiency.

In conclusion, auger powder filling machines play a critical role in various production lines, ensuring accurate and efficient dispensing of powdered substances. By following these tips for optimizing efficiency with auger powder filling machines, companies can improve their production output, reduce waste, and enhance overall performance. Calibration, powder type, maintenance, employee training, automation, and data analysis are key factors to consider when using auger powder filling machines in manufacturing operations. By implementing these strategies, companies can maximize the benefits of this essential equipment and achieve success in their production processes.

Common Challenges and Solutions when Using Auger Powder Filling Machines

Auger powder filling machines are a popular choice for many production lines due to their efficiency and accuracy in filling containers with powdered substances. However, like any piece of equipment, there are common challenges that can arise when using these machines. In this article, we will explore some of these challenges and provide solutions to help ensure smooth operation in various production lines.

One common challenge when using auger powder filling machines is inconsistent filling levels. This can occur due to variations in the density or flowability of the powder being filled. To address this issue, it is important to properly calibrate the machine to account for these variations. Regularly checking and adjusting the settings of the machine can help maintain consistent filling levels and prevent overfilling or underfilling of containers.

Another challenge that can arise with auger powder filling machines is clogging of the auger. This can occur when the powder being filled contains lumps or is not properly conditioned. To prevent clogging, it is important to ensure that the powder is free-flowing and does not contain any large particles. Regularly cleaning and maintaining the auger can also help prevent clogs and ensure smooth operation of the machine.

In addition to inconsistent filling levels and clogging, another common challenge when using auger powder filling machines is dust generation. This can be a safety hazard for workers and can also lead to contamination of the product being filled. To address this issue, it is important to properly seal the machine and use dust collection systems to capture any airborne particles. Regularly cleaning and maintaining the machine can also help reduce dust generation and ensure a clean working environment.

One final challenge that can arise when using auger powder filling machines is product loss. This can occur when the machine is not properly calibrated or when there are leaks in the filling system. To prevent product loss, it is important to regularly inspect the machine for any leaks or malfunctions. Properly calibrating the machine and conducting regular maintenance checks can help prevent product loss and ensure efficient operation of the machine.

In conclusion, auger powder filling machines are a valuable tool in many production lines for filling containers with powdered substances. However, like any piece of equipment, there are common challenges that can arise when using these machines. By properly calibrating the machine, preventing clogging, reducing dust generation, and preventing product loss, these challenges can be addressed and overcome. With proper maintenance and attention to detail, auger powder filling machines can help streamline production processes and ensure accurate and efficient filling of containers.