Table of Contents

Benefits of Using Automated Candy Can Packaging Machinery

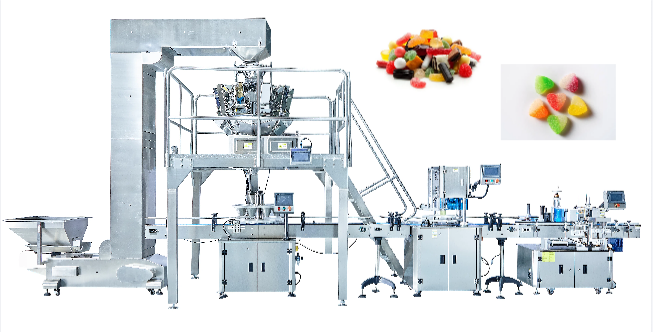

Candy can packaging machinery has revolutionized the way confectionery products are packaged and distributed. With the rise in demand for candy can products, manufacturers are turning to automated packaging machinery to streamline their production processes and increase efficiency. In this article, we will explore the benefits of using automated candy can packaging machinery and why it is essential for manufacturers to invest in this technology.

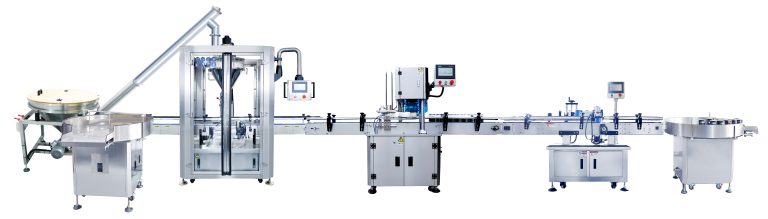

One of the primary benefits of using automated candy can packaging machinery is increased production speed. These machines are designed to package candy cans at a much faster rate than manual labor, allowing manufacturers to meet the high demand for their products. By automating the packaging process, manufacturers can significantly reduce the time it takes to package each candy can, ultimately increasing their overall production output.

In addition to increased production speed, automated candy can packaging machinery also offers improved accuracy and consistency. These machines are programmed to package candy cans with precision, ensuring that each product is packaged correctly and consistently. This level of accuracy is crucial for maintaining the quality of the product and meeting the expectations of consumers. By using automated packaging machinery, manufacturers can eliminate human error and ensure that every candy can is packaged to perfection.

Another significant benefit of using automated candy can packaging machinery is cost savings. While the initial investment in this technology may be high, the long-term cost savings are substantial. By automating the packaging process, manufacturers can reduce labor costs, minimize waste, and increase overall efficiency. Additionally, automated machinery requires less maintenance and downtime, further reducing operational costs and increasing profitability.

Furthermore, automated candy can packaging machinery offers greater flexibility and customization options for manufacturers. These machines can be easily programmed to accommodate different sizes, shapes, and designs of candy cans, allowing manufacturers to meet the diverse needs of their customers. Whether packaging traditional round candy cans or unique novelty shapes, automated machinery can handle a variety of packaging requirements with ease.

Additionally, automated candy can packaging machinery is designed to improve safety in the production environment. By automating the packaging process, manufacturers can reduce the risk of workplace injuries and accidents associated with manual labor. These machines are equipped with advanced safety features and protocols to ensure the well-being of workers and maintain a safe working environment.

Overall, the benefits of using automated candy can packaging machinery are undeniable. From increased production speed and accuracy to cost savings and improved safety, this technology offers manufacturers a competitive edge in the confectionery industry. By investing in automated packaging machinery, manufacturers can enhance their production processes, increase efficiency, and meet the growing demand for candy can products. In conclusion, automated candy can packaging machinery is a valuable asset for manufacturers looking to optimize their production processes and stay ahead in the ever-evolving confectionery market.

Tips for Choosing the Right Candy Can Packaging Machinery for Your Business

Candy can packaging machinery is an essential tool for businesses in the confectionery industry. With the right equipment, companies can efficiently package their products, ensuring they reach customers in perfect condition. However, choosing the right candy can packaging machinery can be a daunting task, given the wide range of options available on the market. In this article, we will provide you with some tips to help you select the best packaging machinery for your business.

First and foremost, it is essential to consider the size and shape of your candy cans. Different packaging machinery is designed to accommodate various sizes and shapes of containers. Therefore, it is crucial to choose equipment that can handle the specific dimensions of your candy cans. This will ensure that your products are packaged securely and efficiently.

Another important factor to consider when selecting candy can packaging machinery is the speed of the equipment. Depending on the volume of production in your business, you may need machinery that can package a high number of candy cans per minute. It is essential to choose equipment that can meet the demands of your production line to avoid bottlenecks and delays.

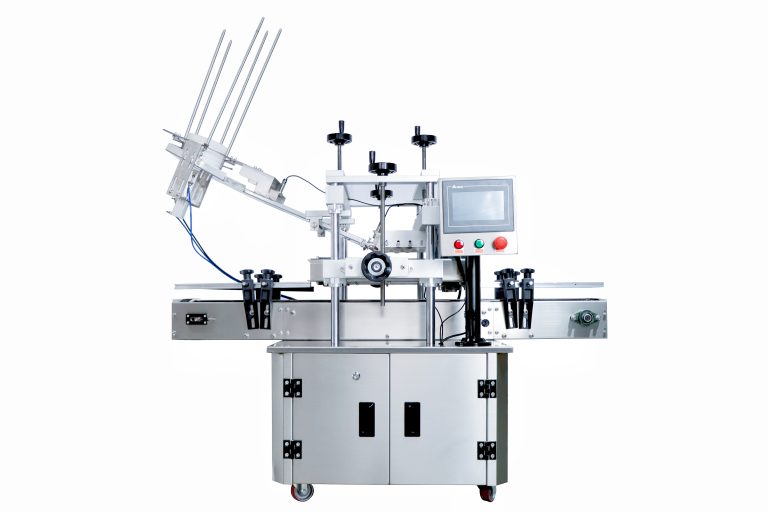

Additionally, it is crucial to consider the level of automation you require in your packaging process. Some candy can packaging machinery is fully automated, while others require manual intervention at various stages of the packaging process. Automated machinery can increase efficiency and reduce the risk of errors, but it may also come with a higher price tag. Therefore, it is essential to weigh the benefits of automation against the cost to determine the best option for your business.

When selecting candy can packaging machinery, it is also important to consider the level of customization required for your packaging process. Some machinery is designed to handle a wide range of packaging materials and can be easily adjusted to accommodate different product specifications. This flexibility can be beneficial if you produce a variety of candy products with different packaging requirements.

Furthermore, it is essential to consider the reliability and durability of the packaging machinery you choose. Investing in high-quality equipment that is built to last can save you money in the long run by reducing maintenance costs and downtime. It is advisable to research the reputation of the manufacturer and read reviews from other customers to ensure you are investing in a reliable product.

In conclusion, selecting the right candy can packaging machinery is crucial for the success of your business. By considering factors such as the size and shape of your candy cans, the speed of the equipment, the level of automation required, the level of customization needed, and the reliability of the machinery, you can make an informed decision that will benefit your production process. Remember to research different options, compare prices, and consult with industry experts to ensure you choose the best packaging machinery for your business.