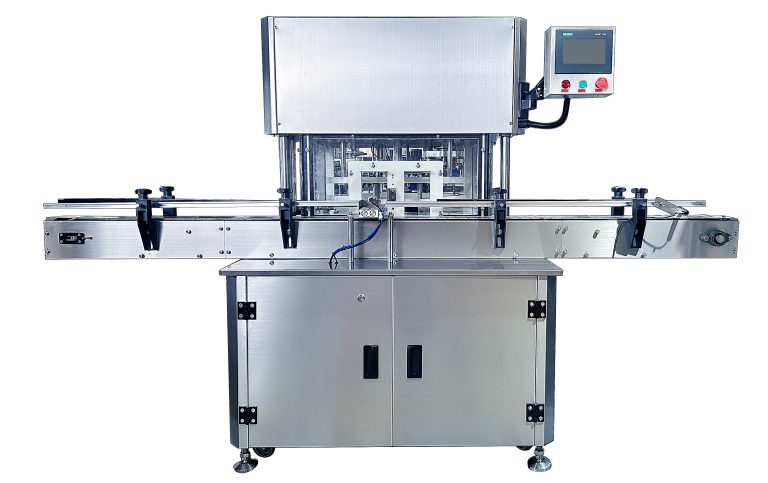

Benefits of Using an Automatic Can-Sealing Machine for Beverage Packaging

In the world of beverage packaging, efficiency is key. With the demand for canned beverages on the rise, manufacturers are constantly looking for ways to streamline their production processes. One solution that has gained popularity in recent years is the automatic can-sealing machine. This innovative piece of equipment offers a range of benefits that can enhance the efficiency of beverage packaging operations.

One of the primary advantages of using an automatic can-sealing machine is its speed. These machines are capable of sealing hundreds of cans per minute, far surpassing the output of manual sealing methods. This increased speed not only allows manufacturers to meet high production demands but also helps to reduce labor costs by minimizing the need for manual labor.

In addition to speed, automatic can-sealing machines also offer a high level of precision. These machines are designed to seal cans with consistent pressure and accuracy, ensuring a tight and secure seal every time. This level of precision helps to minimize the risk of leaks or contamination, which can be costly and damaging to a brand’s reputation.

Furthermore, automatic can-sealing machines are incredibly versatile. They can be easily adjusted to accommodate different can sizes and types, making them suitable for a wide range of beverage packaging needs. This flexibility allows manufacturers to quickly switch between different products without the need for extensive retooling or downtime.

Another key benefit of using an automatic can-sealing machine is its reliability. These machines are built to withstand the rigors of continuous operation, providing consistent performance day in and day out. This reliability helps to minimize downtime and maintenance costs, ensuring that production runs smoothly and efficiently.

In addition to enhancing efficiency, automatic can-sealing machines also offer a range of other benefits. For example, these machines can help to improve the overall quality of the finished product by ensuring a consistent seal and appearance. This can be particularly important for brands looking to maintain a high level of quality and consistency across their product line.

Furthermore, automatic can-sealing machines can help to improve workplace safety by reducing the need for manual labor and minimizing the risk of injuries. By automating the sealing process, manufacturers can create a safer working environment for their employees while also improving overall efficiency.

Overall, the automatic can-sealing machine offers a range of benefits that can enhance the efficiency of beverage packaging operations. From increased speed and precision to versatility and reliability, these machines are a valuable asset for manufacturers looking to streamline their production processes and improve the quality of their products. By investing in an automatic can-sealing machine, beverage manufacturers can stay ahead of the competition and meet the growing demands of today’s market.