Table of Contents

Benefits of Using Square Glass Bottles Vacuum Capping Machine

Square glass bottles vacuum capping machines are a valuable tool for businesses in the food and beverage industry. These machines offer a range of benefits that can help improve efficiency, reduce waste, and ensure product quality. In this article, we will explore some of the key advantages of using a square glass bottles vacuum capping machine.

One of the primary benefits of using a square glass bottles vacuum capping machine is the ability to achieve a tight seal on each bottle. This is essential for preserving the freshness and quality of the product inside. By creating a vacuum seal, these machines help to prevent oxygen from entering the bottle, which can lead to spoilage and degradation of the product. This can help to extend the shelf life of the product and reduce the risk of customer complaints due to spoiled or damaged goods.

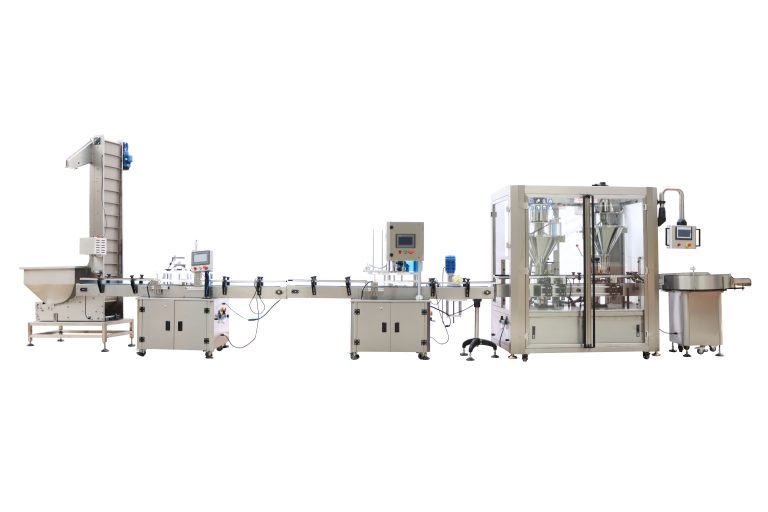

In addition to preserving product quality, square glass bottles vacuum capping machines can also help to improve efficiency in the packaging process. These machines are designed to work quickly and accurately, allowing businesses to cap a large number of bottles in a short amount of time. This can help to streamline production processes and reduce the need for manual labor, saving businesses time and money in the long run.

Another benefit of using a square glass bottles vacuum capping machine is the ability to reduce waste. By creating a tight seal on each bottle, these machines help to prevent leaks and spills that can result in product loss. This can help businesses to minimize waste and maximize their profits by ensuring that every bottle is properly sealed and ready for sale.

Furthermore, square glass bottles vacuum capping machines are versatile and can be used for a wide range of products. Whether you are packaging sauces, dressings, oils, or other liquid products, these machines can help to ensure that each bottle is securely sealed and ready for distribution. This versatility makes them a valuable investment for businesses in the food and beverage industry.

In conclusion, square glass bottles vacuum capping machines offer a range of benefits for businesses looking to improve efficiency, reduce waste, and ensure product quality. By creating a tight seal on each bottle, these machines help to preserve the freshness and integrity of the product inside. They also help to streamline production processes, reduce waste, and can be used for a wide range of products. Overall, square glass bottles vacuum capping machines are a valuable tool for businesses in the food and beverage industry looking to improve their packaging processes and deliver high-quality products to their customers.

How to Choose the Right Square Glass Bottles Vacuum Capping Machine for Your Business

When it comes to packaging products in square glass bottles, having the right vacuum capping machine is essential for ensuring a secure seal and maintaining product freshness. With so many options available on the market, choosing the right machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting a square glass bottles vacuum capping machine to meet your business needs.

One of the first things to consider when choosing a vacuum capping machine is the size and shape of your square glass bottles. Not all machines are designed to accommodate square bottles, so it is important to look for a machine specifically designed for this type of packaging. Additionally, you will need to consider the size of your bottles to ensure that the machine can handle the volume of production you require.

Another important factor to consider is the speed and efficiency of the vacuum capping machine. Depending on the size of your business and the volume of production, you may need a machine that can cap a large number of bottles quickly and efficiently. Look for a machine that offers adjustable speed settings to accommodate different production needs.

In addition to speed and efficiency, it is important to consider the level of automation offered by the vacuum capping machine. Fully automated machines can streamline the capping process and reduce the risk of human error. However, these machines may come with a higher price tag. If budget is a concern, you may opt for a semi-automated machine that still offers some level of automation while being more cost-effective.

When choosing a vacuum capping machine, it is also important to consider the type of caps that will be used on your square glass bottles. Different machines are designed to work with specific types of caps, so be sure to choose a machine that is compatible with the caps you plan to use. Additionally, consider the size and shape of the caps to ensure they will fit securely on your bottles.

Durability and reliability are also key factors to consider when selecting a vacuum capping machine. Look for a machine made from high-quality materials that can withstand the rigors of daily use in a production environment. Additionally, read reviews and testimonials from other users to gauge the reliability of the machine and the level of customer support offered by the manufacturer.

Finally, consider the overall cost of the vacuum capping machine, including any additional features or accessories that may be necessary for your business. While it is important to stay within budget, it is also important to invest in a machine that will meet your production needs and provide a secure seal for your square glass bottles.

In conclusion, choosing the right square glass bottles vacuum capping machine for your business requires careful consideration of factors such as bottle size, speed and efficiency, automation level, cap compatibility, durability, reliability, and overall cost. By taking the time to research and compare different machines, you can find the perfect machine to meet your business needs and ensure the quality and freshness of your products.