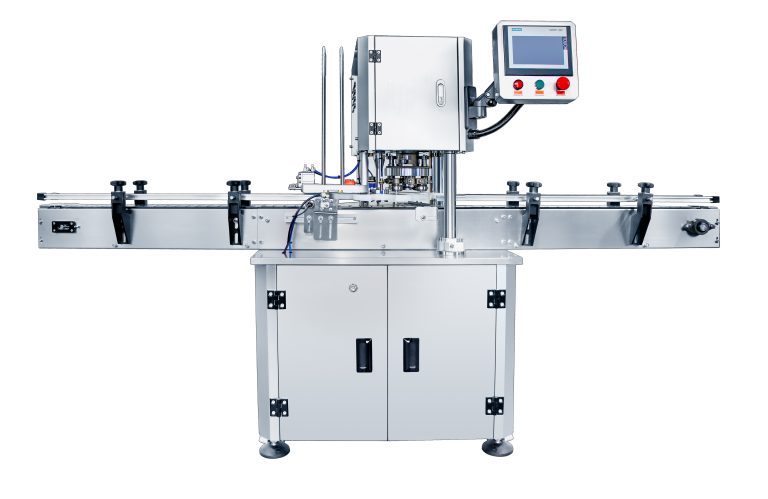

A single-head servo twist-off capping machine is a specialized piece of equipment designed for efficiently and accurately applying twist-off caps to containers.

This type of machine operates through a precise and controlled process. It begins with the containers being positioned on a conveyor or feeding system and moved into the capping station.

The single capping head, driven by servo technology, precisely grips the cap and applies a twisting motion to secure it onto the container. The servo system ensures consistent torque and rotational speed, guaranteeing a uniform and tight seal.

Sensors and control systems monitor the capping process, detecting factors such as the position of the container, the alignment of the cap, and the torque applied. This real-time feedback allows for immediate adjustments to ensure each cap is properly attached.

The machine is often programmable, allowing operators to set specific parameters based on the type of container, cap size, and desired capping specifications. This flexibility enables it to handle a variety of products and packaging requirements.

In summary, a single-head servo twist-off capping machine is a sophisticated device that uses advanced technology to provide reliable and consistent capping, enhancing the quality and integrity of packaged products.