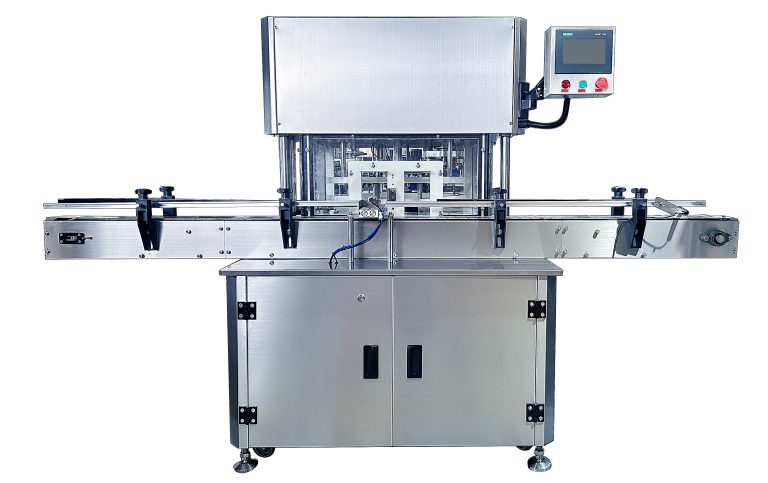

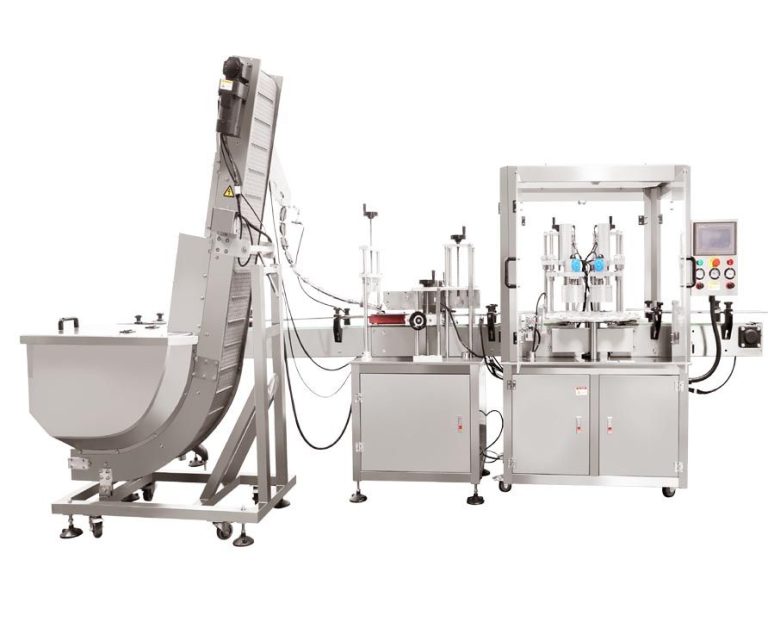

Hybrid linear-rotary filling systems combine the best features of linear and rotary filling methods. The linear component provides precise and controlled movement, ensuring accurate positioning of the packaging containers. Meanwhile, the rotary aspect adds speed and efficiency, allowing for a continuous filling process.

One of the key benefits of these systems is their enhanced flexibility. They can handle a wide variety of granule types, sizes, and packaging formats with ease. This adaptability makes them suitable for diverse product lines and changing market demands.

The increased productivity offered by hybrid systems is another significant factor. They can achieve higher filling rates without sacrificing quality or accuracy, enabling manufacturers to meet growing production volumes in a timely manner.

-1024x683.jpg)

In terms of quality control, these systems incorporate advanced sensors and monitoring capabilities. This ensures consistent filling weights, reduces rejects, and maintains the integrity of the packaged products.

Furthermore, the integration of smart technologies such as artificial intelligence and machine learning allows for predictive maintenance and optimization of the filling process. This not only reduces downtime but also maximizes the system’s overall performance.

The future of granule packaging lies in the adoption of hybrid linear-rotary filling systems. They offer a seamless blend of precision, speed, flexibility, and quality, setting new standards in the packaging industry and enabling businesses to stay competitive in an ever-changing marketplace.