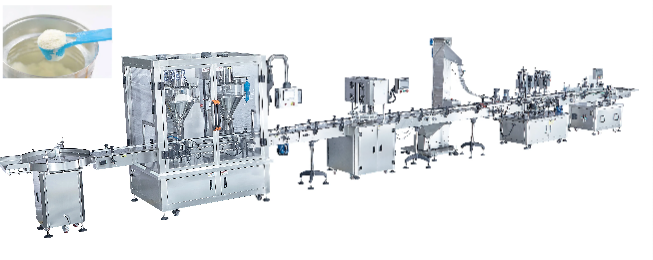

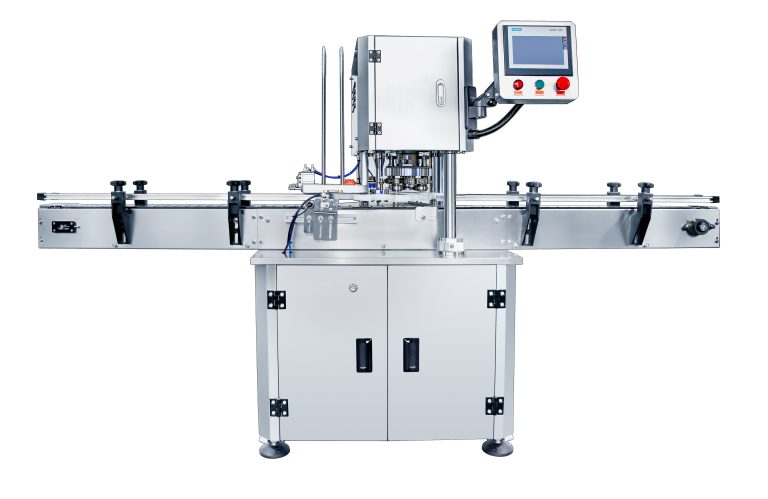

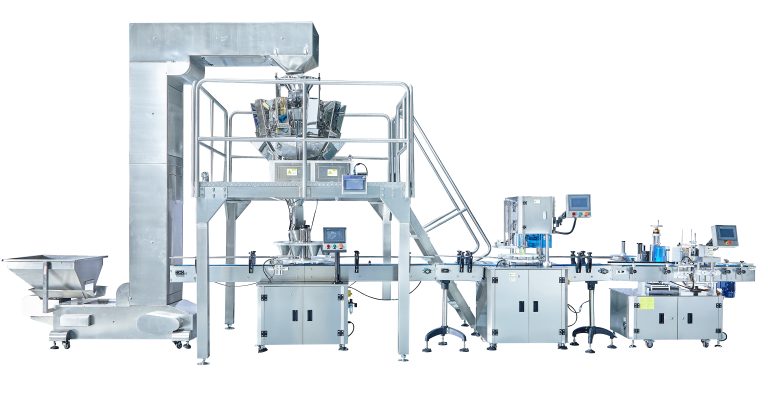

Enhanced Productivity: The dual-head design allows for the simultaneous sealing of two cans, significantly increasing the output rate. This means you can produce more cans in less time, meeting higher production demands and boosting your overall efficiency.

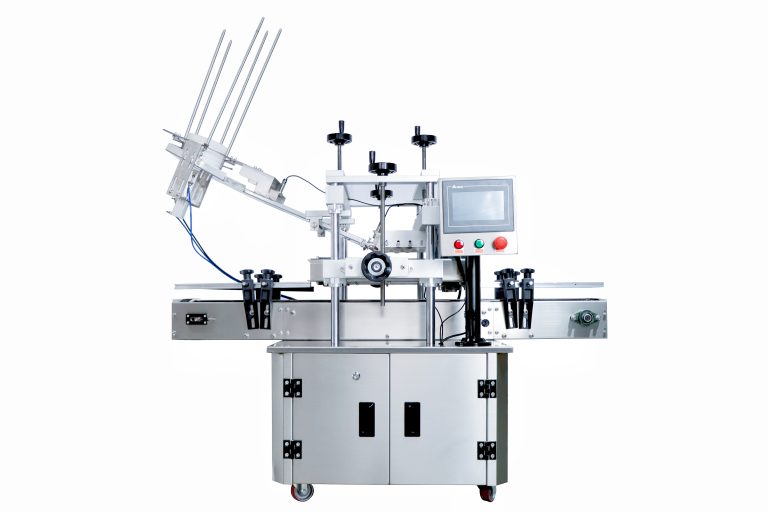

Precision Sealing: The servo technology ensures precise control over the sealing process. This leads to consistently tight and reliable seams, minimizing the risk of leaks and maintaining the quality and freshness of the contents inside the cans.

Versatility: These machines can handle a wide range of can sizes and shapes, giving you the flexibility to adapt to different packaging requirements without the need for extensive adjustments or additional equipment.

Reduced Labor Costs: The automation feature reduces the reliance on manual labor, saving you on wages and potentially reducing the chances of human error that could lead to defective seals.

Improved Consistency: The machine operates with consistent parameters and performance, ensuring that each can is sealed to the same high standards. This helps build a reliable brand image and reduces the likelihood of quality-related issues in the market.

In summary, an automatic dual-head servo can seaming machine offers a combination of increased productivity, superior sealing quality, flexibility, cost savings, and consistent performance, making it a valuable investment for any packaging operation.