Table of Contents

Benefits of Using an Automatic Protein Powder Filler Capper Seamer Labeler Packing Line

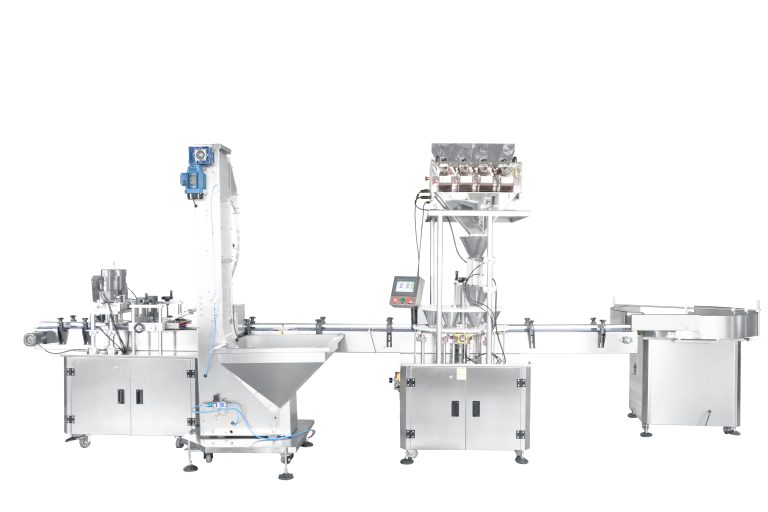

Protein powder is a popular supplement among fitness enthusiasts and athletes looking to increase their protein intake for muscle growth and recovery. With the growing demand for protein powder products, manufacturers are constantly looking for ways to streamline their production processes to meet the needs of consumers. One solution that has gained popularity in recent years is the use of automatic protein powder filler capper seamer labeler packing lines.

These automated packaging lines offer a range of benefits for manufacturers looking to increase efficiency and productivity in their production processes. One of the key advantages of using an automatic protein powder filler capper seamer labeler packing line is the speed at which it can package products. These machines are capable of filling, capping, sealing, and labeling containers at a much faster rate than manual labor, allowing manufacturers to meet high production demands and reduce lead times.

In addition to speed, automatic packaging lines also offer improved accuracy and consistency in the packaging process. By automating the filling, capping, and labeling processes, manufacturers can ensure that each container is filled with the correct amount of product, sealed properly, and labeled accurately. This helps to reduce the risk of errors and inconsistencies in the packaging process, leading to higher quality products and increased customer satisfaction.

Another benefit of using an automatic protein powder filler capper seamer labeler packing line is the reduction in labor costs. By automating the packaging process, manufacturers can reduce the need for manual labor, saving time and money on labor expenses. This allows manufacturers to reallocate resources to other areas of their business, such as product development or marketing, to further grow their brand and increase profitability.

Furthermore, automatic packaging lines also offer improved safety and hygiene in the production process. By minimizing human contact with the product during packaging, manufacturers can reduce the risk of contamination and ensure that products are packaged in a clean and sanitary environment. This is especially important in the food and beverage industry, where product safety and quality are top priorities for consumers.

In addition to these benefits, automatic packaging lines also offer increased flexibility and scalability for manufacturers. These machines are designed to handle a wide range of container sizes and shapes, allowing manufacturers to package products in various formats to meet the needs of different markets and customers. This flexibility also allows manufacturers to easily scale up production as demand for their products grows, without the need for significant investments in additional equipment or resources.

Overall, the use of an automatic protein powder filler capper seamer labeler packing line offers a range of benefits for manufacturers looking to improve efficiency, productivity, and quality in their production processes. From increased speed and accuracy to reduced labor costs and improved safety, these automated packaging lines are a valuable investment for manufacturers looking to stay competitive in the fast-paced world of protein powder production. By leveraging the benefits of automation, manufacturers can streamline their production processes, increase profitability, and deliver high-quality products to their customers.

How to Choose the Right Automatic Protein Powder Filler Capper Seamer Labeler Packing Line for Your Business

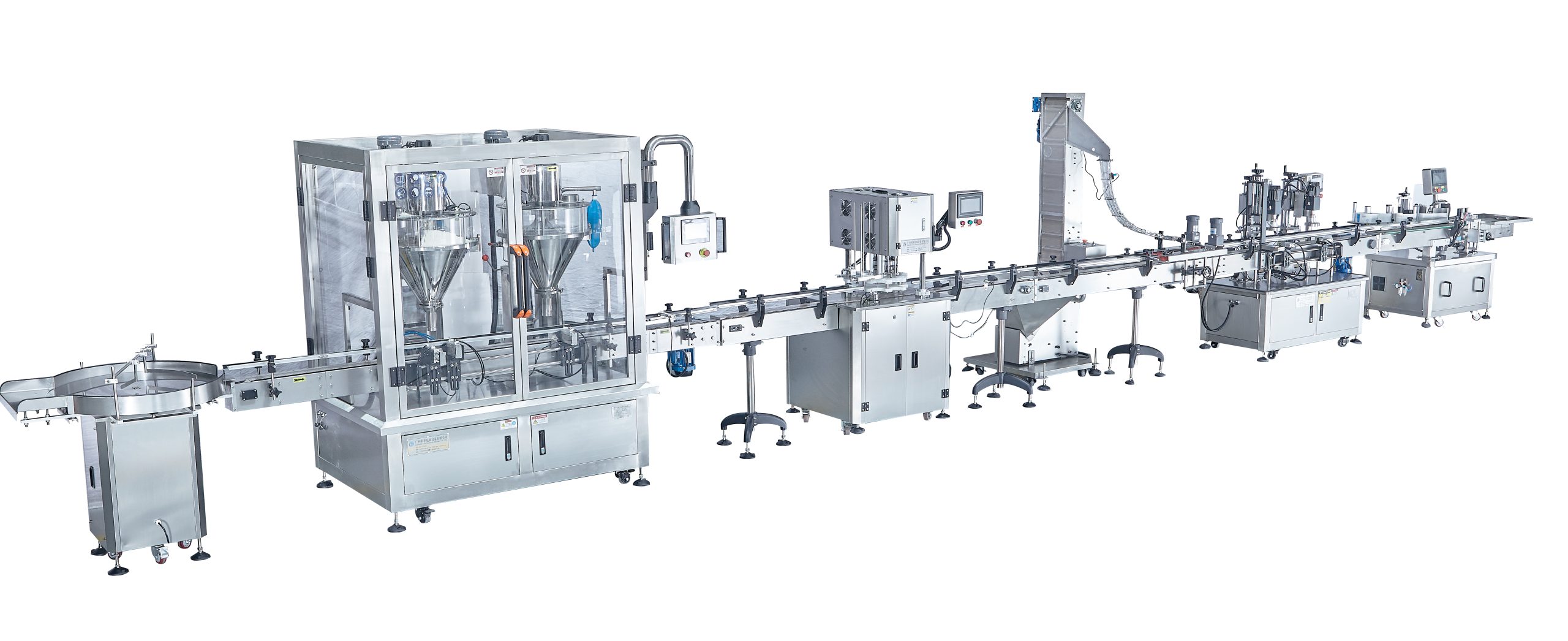

When it comes to packaging protein powder, having an efficient and reliable automatic filling, capping, sealing, labeling, and packing line is essential for any business. With the increasing demand for protein supplements in the health and fitness industry, choosing the right equipment can make a significant difference in the productivity and profitability of your operation.

One of the key factors to consider when selecting an automatic protein powder filler capper seamer labeler packing line is the production capacity. Depending on the size of your business and the volume of protein powder you need to package, you will need to choose a machine that can meet your specific production requirements. It is important to consider not only your current needs but also any potential growth in the future.

Another important consideration is the level of automation that the machine offers. An automatic filling, capping, sealing, labeling, and packing line can significantly increase efficiency and reduce labor costs. Look for a machine that offers features such as automatic feeding, filling, capping, sealing, labeling, and packing to streamline the packaging process and minimize human intervention.

In addition to automation, it is crucial to consider the accuracy and precision of the machine. Protein powder is a fine and powdery substance that can be challenging to handle. Look for a machine that can accurately measure and dispense the correct amount of powder into each container to ensure consistency and quality in your final product.

Furthermore, the reliability and durability of the equipment are essential factors to consider. A protein powder filler capper seamer labeler packing line is a significant investment for any business, so it is crucial to choose a machine that is built to last and can withstand the rigors of continuous use. Look for a machine made from high-quality materials and backed by a reputable manufacturer with a track record of producing reliable equipment.

When choosing an automatic protein powder filler capper seamer labeler packing line, it is also important to consider the flexibility and versatility of the machine. Look for a machine that can accommodate a variety of container sizes and shapes to meet the diverse needs of your customers. Additionally, consider whether the machine can handle different types of packaging materials, such as plastic jars, bottles, or pouches.

Finally, consider the ease of maintenance and serviceability of the equipment. Look for a machine that is easy to clean and maintain to ensure optimal performance and longevity. Additionally, choose a machine that is backed by a manufacturer that offers reliable customer support and service to address any issues that may arise.

In conclusion, choosing the right automatic protein powder filler capper seamer labeler packing line for your business is a crucial decision that can impact the efficiency and profitability of your operation. Consider factors such as production capacity, level of automation, accuracy and precision, reliability and durability, flexibility and versatility, and ease of maintenance when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure that your protein powder packaging process runs smoothly and efficiently.