Table of Contents

Benefits of Using Olive Granules Packing Machine Line

Olive granules are a popular ingredient used in various food products, such as salads, pasta dishes, and marinades. To meet the demand for these products, manufacturers rely on efficient packaging machines to ensure that the granules are properly sealed and preserved. One such machine that has gained popularity in the industry is the olive granules packing machine line.

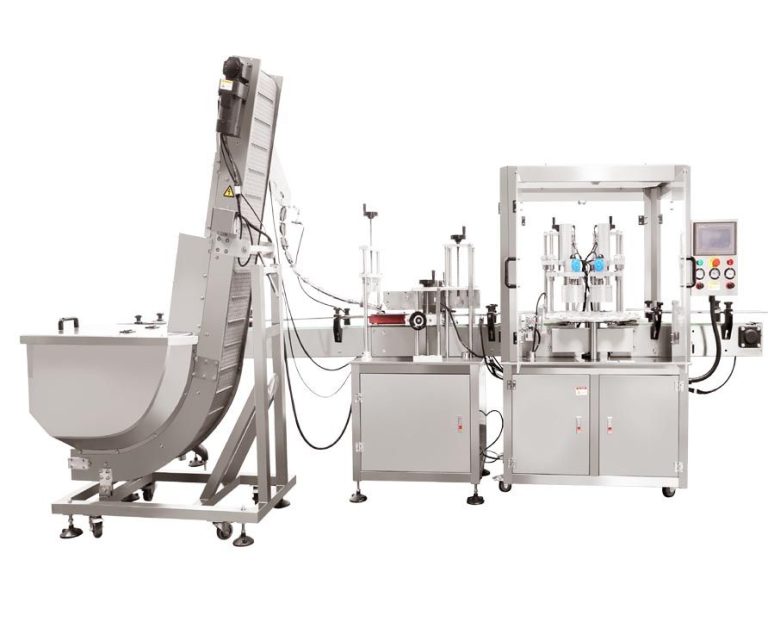

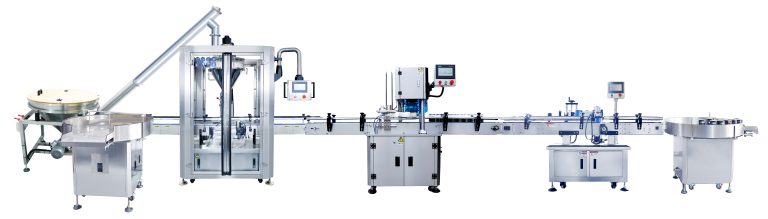

The olive granules packing machine line is a comprehensive solution that streamlines the packaging process from start to finish. It consists of several components, including a filling machine, a sealing machine, and a labeling machine. These machines work together seamlessly to ensure that the granules are accurately measured, sealed in airtight packaging, and labeled with important information such as expiration dates and batch numbers.

One of the key benefits of using an olive granules packing machine line is its efficiency. These machines are designed to handle high volumes of granules quickly and accurately, reducing the need for manual labor and increasing productivity. This is especially important for manufacturers who need to meet tight production deadlines and deliver products to market in a timely manner.

In addition to efficiency, the olive granules packing machine line also offers precision and consistency in packaging. The machines are equipped with advanced technology that ensures the granules are measured and sealed with precision, eliminating the risk of underfilling or overfilling. This level of accuracy is crucial for maintaining product quality and meeting regulatory standards.

Furthermore, the olive granules packing machine line helps to extend the shelf life of the granules by sealing them in airtight packaging. This prevents exposure to air, moisture, and contaminants, which can cause the granules to spoil or lose their freshness. By preserving the quality of the granules, manufacturers can ensure that their products reach consumers in optimal condition.

Another benefit of using an olive granules packing machine line is its versatility. These machines can be customized to accommodate different packaging sizes and formats, allowing manufacturers to package their granules in various ways to meet the needs of different markets. Whether it’s small sachets for individual servings or larger bags for bulk purchases, the olive granules packing machine line can handle it all.

Additionally, the olive granules packing machine line is easy to operate and maintain, making it a cost-effective solution for manufacturers. The machines are designed for user-friendly operation, with intuitive controls and minimal training required. They are also built to withstand the rigors of continuous use, reducing the need for frequent repairs and maintenance.

Overall, the olive granules packing machine line offers a range of benefits for manufacturers looking to streamline their packaging process and deliver high-quality products to consumers. From efficiency and precision to versatility and ease of use, these machines are a valuable investment for any food production facility. By incorporating an olive granules packing machine line into their operations, manufacturers can improve productivity, reduce costs, and enhance the overall quality of their products.

How to Choose the Right Olive Granules Packing Machine Line for Your Business

When it comes to packaging olive granules, having the right equipment is essential to ensure efficiency and quality. A packing machine line specifically designed for olive granules can streamline the packaging process and help you meet the demands of your business. However, with so many options available on the market, choosing the right olive granules packing machine line can be a daunting task. In this article, we will discuss some key factors to consider when selecting a packing machine line for your olive granules business.

One of the first things to consider when choosing a packing machine line for olive granules is the production capacity of the machine. You will need to determine how much product you need to package on a daily basis in order to select a machine that can meet your production requirements. It is important to choose a machine that can handle the volume of olive granules you need to package without causing bottlenecks in your production line.

In addition to production capacity, you should also consider the speed of the packing machine line. A faster machine can help you increase efficiency and meet tight deadlines, but it is important to balance speed with accuracy. Look for a machine that can package olive granules quickly without compromising the quality of the packaging.

Another important factor to consider when choosing a packing machine line for olive granules is the type of packaging materials the machine can handle. Some machines are designed to work with specific types of packaging materials, such as bags or pouches, while others are more versatile and can accommodate a variety of packaging options. Consider the type of packaging materials you will be using for your olive granules and choose a machine that is compatible with those materials.

It is also important to consider the level of automation offered by the packing machine line. Fully automated machines can help you save time and labor costs by reducing the need for manual intervention in the packaging process. However, fully automated machines can be more expensive than semi-automated or manual machines. Consider your budget and production requirements when deciding on the level of automation that is right for your business.

When choosing a packing machine line for olive granules, it is important to consider the overall reliability and durability of the machine. Look for a machine that is built to last and can withstand the rigors of daily use in a production environment. A reliable machine will help you avoid costly downtime and maintenance issues that can disrupt your production schedule.

In conclusion, choosing the right olive granules packing machine line for your business is a crucial decision that can impact the efficiency and quality of your packaging process. Consider factors such as production capacity, speed, packaging materials, automation level, and reliability when selecting a packing machine line for your olive granules business. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure that your packaging process runs smoothly and efficiently.

Tips for Maintaining and Troubleshooting Olive Granules Packing Machine Line

Olive granules packing machine lines are essential for efficiently packaging olive granules for distribution and sale. To ensure that these machines operate smoothly and effectively, it is important to properly maintain and troubleshoot them. By following these tips, you can maximize the performance of your olive granules packing machine line and minimize downtime.

Regular maintenance is key to keeping your olive granules packing machine line in top condition. One important aspect of maintenance is keeping the machine clean. Regularly cleaning the machine helps prevent build-up of dirt and debris, which can cause the machine to malfunction. It is also important to regularly inspect the machine for any signs of wear and tear, such as loose or damaged parts. By addressing these issues promptly, you can prevent more serious problems from occurring.

In addition to regular cleaning and inspection, it is important to follow the manufacturer’s recommended maintenance schedule. This may include tasks such as lubricating moving parts, replacing worn components, and calibrating the machine. By following the manufacturer’s guidelines, you can ensure that your olive granules packing machine line operates at peak performance.

Despite regular maintenance, issues may still arise with your olive granules packing machine line. When troubleshooting these issues, it is important to approach the problem systematically. Start by identifying the specific issue that is causing the machine to malfunction. This may involve observing the machine in action, listening for unusual noises, or checking for error messages on the control panel.

Once you have identified the issue, you can begin troubleshooting. One common issue with olive granules packing machine lines is jammed or misaligned components. If you suspect that this is the problem, carefully inspect the machine to locate the source of the jam or misalignment. Once you have identified the issue, you can take steps to correct it, such as clearing the jam or realigning the components.

Another common issue with olive granules packing machine lines is faulty sensors or controls. If you suspect that this is the problem, check the sensors and controls for any signs of damage or malfunction. If necessary, replace the faulty components to restore the machine to proper working order.

In some cases, troubleshooting may require more advanced techniques, such as adjusting the machine’s settings or recalibrating its controls. If you are unsure how to perform these tasks, consult the machine’s manual or contact the manufacturer for assistance. By taking a systematic approach to troubleshooting, you can quickly identify and resolve issues with your olive granules packing machine line.

In conclusion, proper maintenance and troubleshooting are essential for keeping your olive granules packing machine line running smoothly. By following these tips, you can maximize the performance of your machine and minimize downtime. Remember to regularly clean and inspect the machine, follow the manufacturer’s maintenance schedule, and approach troubleshooting systematically. By taking these steps, you can ensure that your olive granules packing machine line operates at peak performance for years to come.