Inhoudsopgave

Benefits of Implementing a Can Packaging Line in Industrial Processes

In the world of industrial manufacturing, efficiency and productivity are key factors in ensuring success. One important aspect of this is the packaging process, which plays a crucial role in the overall production line. Can packaging lines are a vital component of many industrial processes, providing a streamlined and efficient way to package products for distribution.

Implementing a can packaging line in industrial processes offers a wide range of benefits. One of the most significant advantages is the increase in production speed and efficiency. Can packaging lines are designed to automate the packaging process, reducing the need for manual labor and increasing the speed at which products can be packaged. This not only saves time but also allows for higher production volumes, ultimately leading to increased profitability for the company.

Another key benefit of implementing a can packaging line is the improvement in product quality and consistency. Manual packaging processes can often lead to inconsistencies in the packaging of products, which can affect the overall quality and appearance of the final product. Can packaging lines are designed to ensure that each product is packaged in a uniform and consistent manner, resulting in a higher quality end product that meets the standards of both the company and the consumer.

In addition to improving production speed and product quality, can packaging lines also offer cost savings for industrial manufacturers. By automating the packaging process, companies can reduce the need for manual labor, which can be a significant cost savings in the long run. Additionally, can packaging lines are designed to be highly efficient, reducing waste and minimizing the risk of errors in the packaging process. This can lead to further cost savings for the company and ultimately improve the bottom line.

Furthermore, implementing a can packaging line can also improve workplace safety for employees. Manual packaging processes can be physically demanding and repetitive, leading to an increased risk of injury for workers. Can packaging lines are designed to automate the packaging process, reducing the need for manual labor and minimizing the risk of injury for employees. This not only creates a safer work environment but also improves employee morale and productivity.

Overall, the implementation of a can packaging line in industrial processes plays a crucial role in the development and success of industrial manufacturing. From increasing production speed and efficiency to improving product quality and consistency, can packaging lines offer a wide range of benefits for companies looking to streamline their packaging processes. Additionally, the cost savings and improved workplace safety that come with implementing a can packaging line make it a valuable investment for industrial manufacturers looking to stay competitive in today’s market.

In conclusion, can packaging lines are an essential component of industrial manufacturing processes, offering a wide range of benefits that can help companies improve efficiency, productivity, and profitability. By automating the packaging process, companies can increase production speed, improve product quality, reduce costs, and create a safer work environment for employees. Ultimately, the implementation of a can packaging line is a valuable investment for companies looking to stay ahead in today’s competitive industrial landscape.

How Can Packaging Line Improves Efficiency and Productivity in Manufacturing Industries

In the world of manufacturing industries, efficiency and productivity are key factors that can make or break a business. One crucial aspect of achieving these goals is the implementation of a well-designed can packaging line. Can packaging lines play a vital role in streamlining the production process, ensuring that products are packaged quickly and accurately. This not only saves time and labor costs but also helps to maintain the quality and consistency of the final product.

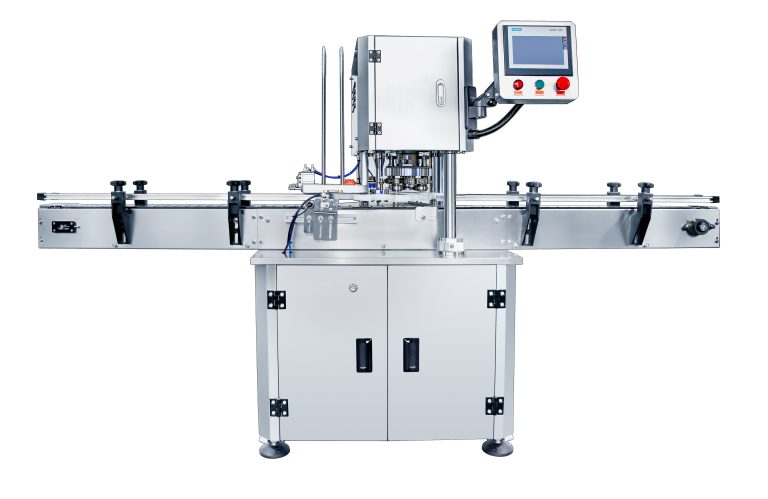

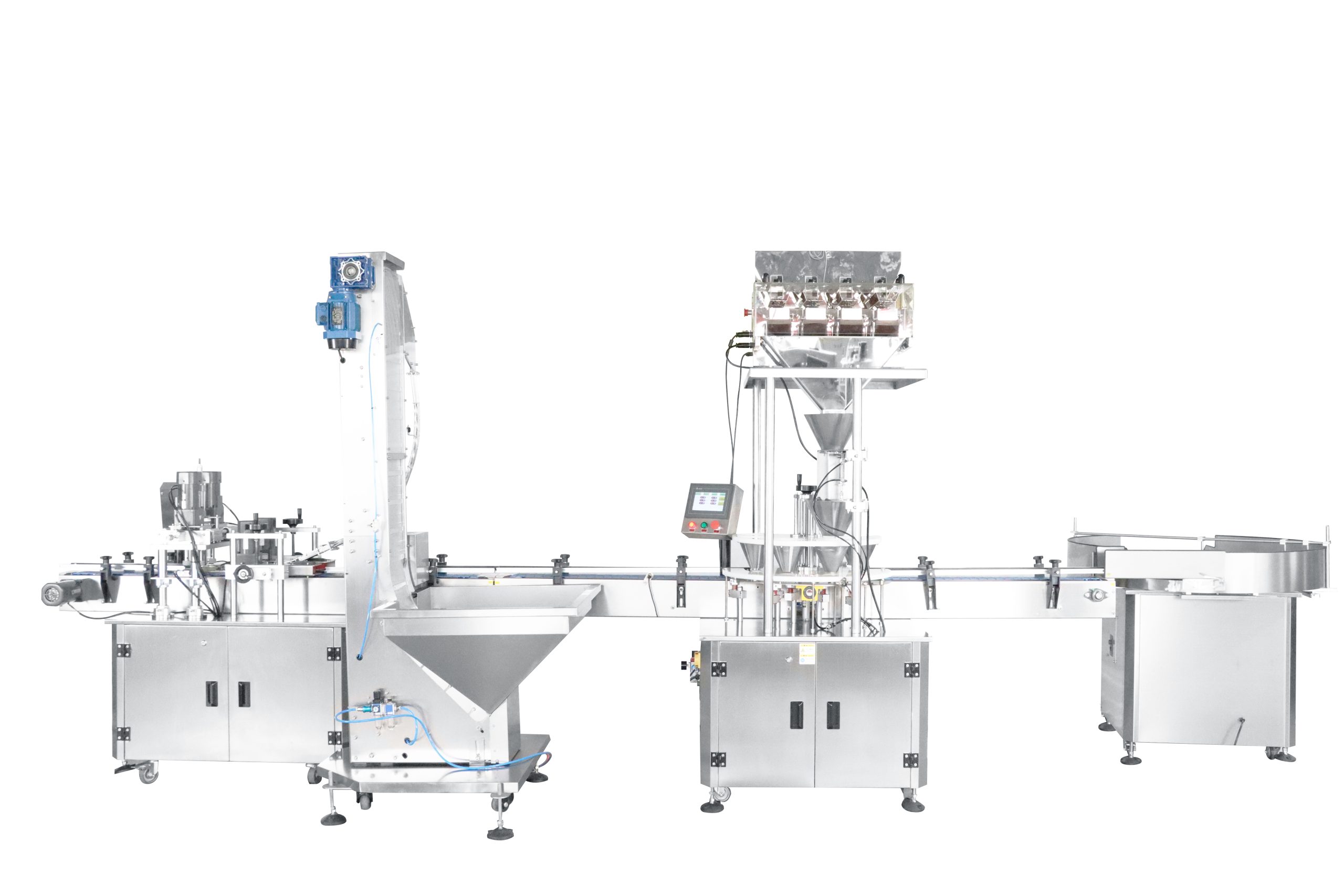

One of the primary ways in which can packaging lines improve efficiency is by automating the packaging process. By using automated machinery to fill, seal, and label cans, manufacturers can significantly reduce the amount of manual labor required. This not only speeds up the packaging process but also minimizes the risk of human error, resulting in a more consistent and reliable end product. Additionally, automated can packaging lines can operate continuously, 24 hours a day, seven days a week, further increasing productivity and output.

Another key benefit of can packaging lines is their ability to handle a wide range of can sizes and shapes. This flexibility allows manufacturers to package a variety of products on the same line, without the need for costly and time-consuming changeovers. By simply adjusting the settings on the machinery, manufacturers can switch between different can sizes and shapes quickly and easily, maximizing efficiency and minimizing downtime.

Furthermore, can packaging lines are designed to optimize space and layout, making the most of the available floor space in a manufacturing facility. By arranging the machinery in a logical and efficient manner, manufacturers can minimize the distance that cans need to travel during the packaging process, reducing the risk of damage and ensuring a smooth and continuous flow of production. This not only improves efficiency but also helps to create a safer and more organized work environment for employees.

In addition to improving efficiency and productivity, can packaging lines also play a crucial role in ensuring the quality and safety of the final product. By using automated machinery to handle and package cans, manufacturers can minimize the risk of contamination and ensure that products are sealed and labeled correctly. This not only helps to maintain the integrity of the product but also ensures compliance with industry regulations and standards.

Overall, can packaging lines are an essential component of modern manufacturing industries, helping to improve efficiency, productivity, and quality. By automating the packaging process, handling a variety of can sizes and shapes, and optimizing space and layout, can packaging lines play a vital role in streamlining production and ensuring the success of a business. As technology continues to advance, the role of can packaging lines in industrial development will only become more important, driving innovation and growth in the manufacturing sector.