Table of Contents

Benefits of Using Mix Nuts Filling Sealing Capping Labeling Packaging Line

Mix nuts are a popular snack enjoyed by people all over the world. They are not only delicious but also packed with essential nutrients that provide numerous health benefits. In recent years, the demand for mix nuts has been steadily increasing, leading to the need for efficient and reliable packaging solutions. This is where mix nuts filling sealing capping labeling packaging lines come into play.

One of the main benefits of using a mix nuts filling sealing capping labeling packaging line is efficiency. These automated systems are designed to streamline the packaging process, allowing for faster production and increased output. By automating the filling, sealing, capping, labeling, and packaging of mix nuts, companies can significantly reduce the time and labor required to package their products. This not only saves money but also ensures that the products are packaged consistently and accurately every time.

Another benefit of using a mix nuts filling sealing capping labeling packaging line is improved product quality. These systems are equipped with advanced technology that ensures the mix nuts are sealed and packaged in a way that preserves their freshness and flavor. This helps to extend the shelf life of the products and maintain their quality for longer periods. Additionally, the automated labeling process ensures that each package is accurately labeled with the necessary information, such as ingredients, nutritional information, and expiration dates.

In addition to efficiency and product quality, mix nuts filling sealing capping labeling packaging lines also offer increased flexibility. These systems can be easily customized to accommodate different packaging sizes and formats, allowing companies to package their mix nuts in various ways to meet the needs of their customers. Whether it’s individual snack packs, bulk packaging, or custom packaging designs, these systems can handle it all with ease.

Furthermore, mix nuts filling sealing capping labeling packaging lines are designed to improve safety and hygiene in the packaging process. By automating the filling and sealing of mix nuts, companies can reduce the risk of contamination and ensure that the products are packaged in a clean and sanitary environment. This helps to protect the integrity of the products and maintain the trust of consumers.

Overall, the benefits of using a mix nuts filling sealing capping labeling packaging line are clear. From increased efficiency and product quality to improved flexibility and safety, these systems offer a range of advantages for companies looking to streamline their packaging process. By investing in a mix nuts filling sealing capping labeling packaging line, companies can not only save time and money but also ensure that their products are packaged to the highest standards.

How to Optimize Efficiency in Mix Nuts Filling Sealing Capping Labeling Packaging Line

In the food industry, efficiency is key to success. When it comes to packaging lines for products like mix nuts, optimizing efficiency is crucial to meet production demands and ensure quality control. One way to achieve this is by implementing a filling, sealing, capping, labeling, and packaging line that is designed to streamline the process from start to finish.

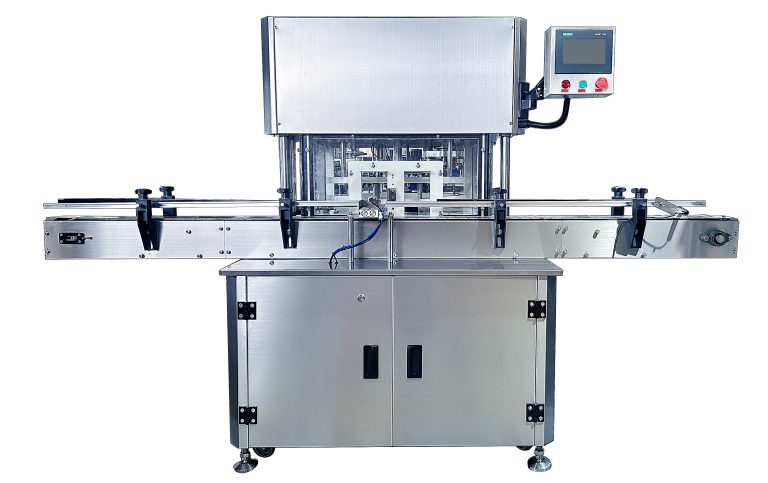

To begin with, the filling stage is where the mix nuts are loaded into containers. This step can be optimized by using a high-speed filling machine that can accurately dispense the correct amount of product into each container. This not only speeds up the process but also reduces waste and ensures consistency in the final product.

Once the containers are filled, they need to be sealed to prevent contamination and maintain freshness. A sealing machine that can quickly and effectively seal each container is essential for efficiency. This machine should be able to handle a variety of container sizes and materials to accommodate different packaging requirements.

After sealing, the containers need to be capped to further protect the product. A capping machine that can securely seal each container with the appropriate cap is essential for maintaining product integrity. This machine should be able to handle different types of caps and apply them quickly and accurately.

Next, the containers need to be labeled with important information such as ingredients, expiration dates, and barcodes. A labeling machine that can print and apply labels efficiently is crucial for compliance with regulations and customer expectations. This machine should be able to handle different label sizes and shapes to accommodate various packaging designs.

Finally, the labeled containers need to be packaged for distribution. A packaging machine that can efficiently pack the containers into boxes or crates is essential for streamlining the process. This machine should be able to handle different packaging materials and sizes to meet the needs of different distribution channels.

By implementing a filling, sealing, capping, labeling, and packaging line that is designed for efficiency, food manufacturers can optimize their production process and meet the demands of the market. This not only improves productivity but also ensures the quality and safety of the final product.

In conclusion, optimizing efficiency in a mix nuts filling, sealing, capping, labeling, and packaging line is essential for success in the food industry. By using high-speed machines that can accurately and quickly perform each step of the process, manufacturers can streamline production and meet customer expectations. Investing in the right equipment and technology is key to achieving this goal and staying competitive in the market.

Latest Technological Advancements in Mix Nuts Filling Sealing Capping Labeling Packaging Line

Mix nuts have become a popular snack choice for many consumers due to their health benefits and delicious taste. As the demand for mix nuts continues to rise, manufacturers are constantly looking for ways to improve their production processes to meet this growing demand. One area where significant advancements have been made is in the mix nuts filling sealing capping labeling packaging line.

One of the latest technological advancements in mix nuts filling sealing capping labeling packaging line is the use of automated systems. These systems are designed to streamline the production process, increase efficiency, and reduce the risk of human error. By automating the filling, sealing, capping, labeling, and packaging processes, manufacturers can significantly increase their output while maintaining high levels of quality and consistency.

Another key advancement in mix nuts filling sealing capping labeling packaging line is the use of advanced sensors and monitoring systems. These systems are able to detect any issues or abnormalities in the production process in real-time, allowing for immediate intervention and correction. This helps to minimize downtime and reduce the risk of product defects, ensuring that only high-quality mix nuts reach the consumer.

Furthermore, the integration of smart technology into mix nuts filling sealing capping labeling packaging line has revolutionized the way manufacturers operate. Smart technology allows for remote monitoring and control of the production line, giving manufacturers greater flexibility and control over their operations. This not only improves efficiency but also allows for quick adjustments to be made in response to changing market demands.

In addition to automation and smart technology, advancements in packaging materials have also played a significant role in improving the mix nuts filling sealing capping labeling packaging line. Manufacturers now have access to a wide range of packaging materials that offer enhanced protection, preservation, and shelf life for mix nuts. From barrier films to vacuum-sealed bags, these materials help to maintain the freshness and quality of the product, ensuring that consumers receive a superior product every time.

Moreover, sustainability has become a key focus in the mix nuts filling sealing capping labeling packaging line. Manufacturers are increasingly turning to eco-friendly packaging materials and processes to reduce their environmental impact. From biodegradable packaging to energy-efficient production methods, sustainability is now a top priority for many manufacturers in the mix nuts industry.

Overall, the latest technological advancements in mix nuts filling sealing capping labeling packaging line have revolutionized the way manufacturers operate. From automation and smart technology to advanced sensors and sustainable packaging materials, these advancements have helped to improve efficiency, quality, and sustainability in the production process. As the demand for mix nuts continues to grow, manufacturers will need to continue to innovate and adapt to stay ahead of the competition and meet the needs of consumers.