Table of Contents

Benefits of Using Lotus Root Powder in Packaging Line

Lotus root powder has been gaining popularity in the food industry for its numerous health benefits and versatility in cooking. This nutritious ingredient is not only delicious but also offers a wide range of benefits when used in a packaging line. In this article, we will explore the advantages of incorporating lotus root powder into your packaging line.

One of the key benefits of using lotus root powder in a packaging line is its ability to extend the shelf life of products. Lotus root powder contains natural antioxidants that help prevent oxidation and spoilage, keeping products fresh for longer periods. This can be particularly beneficial for companies looking to reduce food waste and improve the overall quality of their products.

In addition to its preservation properties, lotus root powder also acts as a natural thickening agent in food products. This can be especially useful in packaging lines where consistency and texture are important factors. By adding lotus root powder to products such as sauces, soups, and dressings, manufacturers can achieve a smooth and creamy texture without the need for artificial thickeners or stabilizers.

Furthermore, lotus root powder is a gluten-free and non-GMO ingredient, making it a popular choice for consumers with dietary restrictions or preferences. By incorporating lotus root powder into their packaging line, companies can cater to a wider range of customers and appeal to health-conscious consumers looking for clean and natural ingredients.

Another advantage of using lotus root powder in a packaging line is its versatility in product development. This ingredient can be used in a variety of food products, including baked goods, snacks, and beverages, allowing manufacturers to create innovative and unique offerings for their customers. Whether used as a flavor enhancer, thickening agent, or nutritional supplement, lotus root powder adds value to products and enhances their overall appeal.

Moreover, lotus root powder is rich in essential nutrients such as vitamins, minerals, and dietary fiber, making it a healthy addition to any packaging line. By incorporating this ingredient into their products, companies can boost the nutritional profile of their offerings and appeal to health-conscious consumers seeking wholesome and nourishing options.

In conclusion, the benefits of using lotus root powder in a packaging line are numerous and varied. From extending shelf life and improving texture to catering to dietary restrictions and enhancing nutritional value, this versatile ingredient offers a range of advantages for manufacturers and consumers alike. By incorporating lotus root powder into their products, companies can create high-quality offerings that stand out in the market and meet the evolving needs of today’s health-conscious consumers.

How to Optimize Efficiency in Lotus Root Powder Can Packaging Line

Lotus root powder is a popular ingredient in many Asian cuisines, known for its unique flavor and health benefits. As demand for this product continues to grow, manufacturers are constantly looking for ways to optimize efficiency in their packaging lines to meet the increasing market demands. One key aspect of this process is the can packaging line, where the lotus root powder is filled, sealed, and labeled before being shipped out to retailers and consumers.

To ensure that the can packaging line operates at maximum efficiency, it is important to carefully plan and organize the workflow. This includes determining the optimal layout of the equipment, as well as establishing clear procedures for each step of the packaging process. By streamlining the workflow and eliminating unnecessary steps, manufacturers can reduce downtime and increase productivity.

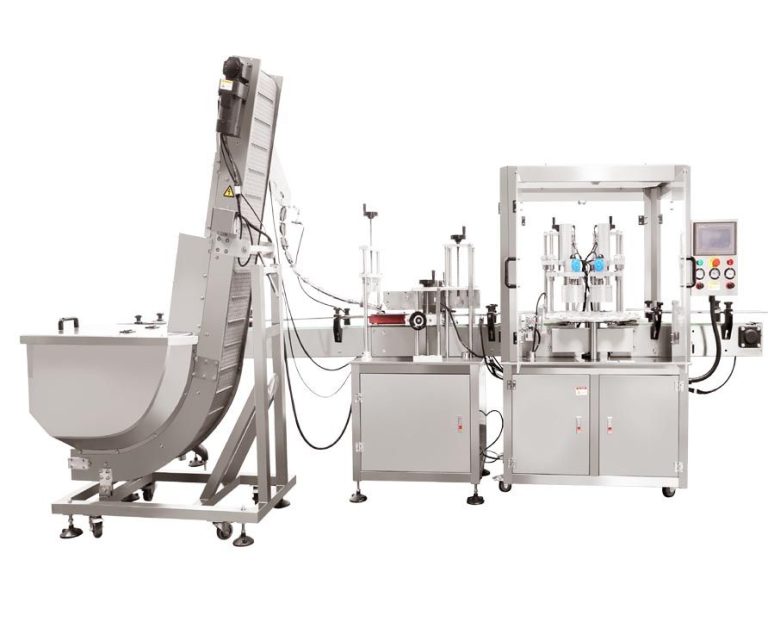

Another important factor in optimizing efficiency in the can packaging line is the use of automation technology. Automated equipment can significantly speed up the packaging process, allowing for faster production and higher output. This can help manufacturers meet tight deadlines and fulfill large orders more quickly, ultimately improving customer satisfaction and increasing profitability.

In addition to automation, it is also important to invest in high-quality equipment that is reliable and durable. This includes filling machines, sealing machines, labeling machines, and other packaging equipment. By using top-of-the-line equipment, manufacturers can minimize the risk of breakdowns and ensure that the packaging line runs smoothly and efficiently.

Regular maintenance and servicing of the equipment is also crucial to optimizing efficiency in the can packaging line. By keeping the machinery in good working condition, manufacturers can prevent unexpected breakdowns and minimize downtime. This can help to avoid costly delays in production and ensure that orders are completed on time.

Furthermore, it is important to train staff properly on how to operate the equipment and follow the packaging procedures. Well-trained employees are more likely to work efficiently and effectively, reducing the risk of errors and improving overall productivity. By investing in employee training and development, manufacturers can create a skilled workforce that is capable of running the can packaging line at peak efficiency.

To further optimize efficiency in the can packaging line, manufacturers should also consider implementing quality control measures. This includes regular inspections of the packaging materials, as well as testing the filled cans for accuracy and consistency. By maintaining high quality standards, manufacturers can ensure that their products meet customer expectations and comply with industry regulations.

In conclusion, optimizing efficiency in the lotus root powder can packaging line is essential for manufacturers looking to meet the growing demand for this popular product. By carefully planning the workflow, investing in automation technology, using high-quality equipment, maintaining machinery, training staff, and implementing quality control measures, manufacturers can streamline their packaging process and increase productivity. Ultimately, by optimizing efficiency in the can packaging line, manufacturers can improve customer satisfaction, reduce costs, and stay competitive in the market.