Table of Contents

Emerging Trends in Liquid Filling and Sealing Machine Line Global Market

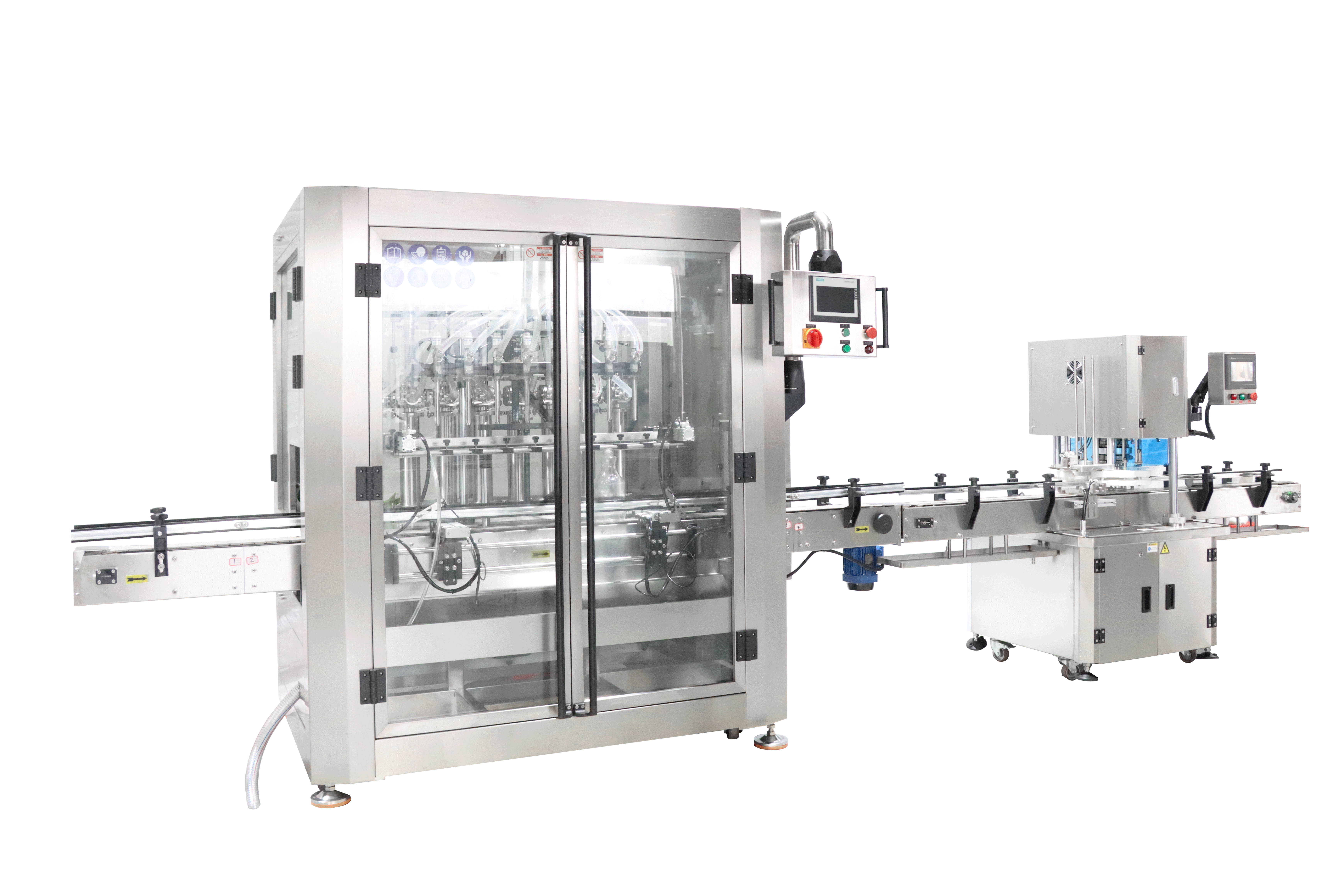

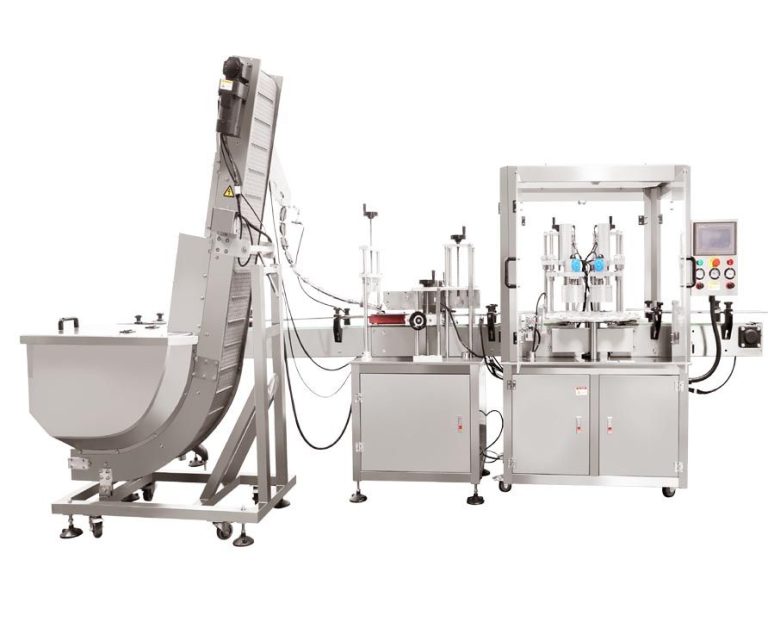

The global market for liquid filling and sealing machines is experiencing significant growth, driven by the increasing demand for efficient and automated packaging solutions across various industries. These machines play a crucial role in the packaging process by accurately filling containers with liquid products and sealing them to ensure product integrity and safety.

One of the key trends in the liquid filling and sealing machine market is the growing adoption of advanced technologies such as robotics and automation. Manufacturers are increasingly investing in these technologies to improve the efficiency and accuracy of their packaging processes. Automated filling and sealing machines not only help in reducing labor costs but also minimize the risk of human error, resulting in higher productivity and consistent product quality.

Another emerging trend in the market is the focus on sustainability and eco-friendly packaging solutions. With increasing awareness about environmental issues, manufacturers are looking for ways to reduce their carbon footprint and minimize waste. As a result, there is a growing demand for liquid filling and sealing machines that are designed to use less energy and produce less waste. Some manufacturers are also exploring the use of biodegradable materials for packaging to further reduce their environmental impact.

The food and beverage industry is one of the major end-users of liquid filling and sealing machines, and this sector is witnessing a surge in demand for these machines. With the growing popularity of convenience foods and beverages, manufacturers are looking for efficient and reliable packaging solutions to meet the increasing demand from consumers. Liquid filling and sealing machines play a crucial role in ensuring that products are packaged safely and efficiently, meeting the stringent quality standards of the industry.

In addition to the food and beverage industry, the pharmaceutical and cosmetic industries are also driving the growth of the liquid filling and sealing machine market. These industries have strict regulations and quality standards when it comes to packaging, and manufacturers are increasingly turning to automated filling and sealing machines to ensure compliance with these standards. These machines help in maintaining the integrity of the products and reducing the risk of contamination, making them an essential part of the packaging process in these industries.

The global market for liquid filling and sealing machines is highly competitive, with several key players dominating the market. These players are constantly innovating and introducing new technologies to stay ahead of the competition. Some of the key trends in the market include the development of multi-functional machines that can handle different types of containers and products, as well as the integration of smart technologies such as IoT and AI to improve efficiency and productivity.

Overall, the liquid filling and sealing machine market is witnessing rapid growth, driven by the increasing demand for efficient and automated packaging solutions across various industries. With the adoption of advanced technologies and a focus on sustainability, manufacturers are looking for innovative solutions to meet the evolving needs of the market. As the market continues to evolve, we can expect to see further advancements in liquid filling and sealing machines that will revolutionize the packaging industry.

Impact of Technological Advancements on Liquid Filling and Sealing Machine Line Global Market

The global market for liquid filling and sealing machines has seen significant growth in recent years, thanks in large part to technological advancements in the industry. These advancements have not only improved the efficiency and accuracy of liquid filling and sealing machines but have also expanded their capabilities, making them more versatile and adaptable to a wide range of products and industries.

One of the key technological advancements that has had a major impact on the liquid filling and sealing machine market is the development of automated systems. Automated liquid filling and sealing machines are able to perform tasks with a level of speed and precision that is simply not possible with manual systems. This has led to increased productivity and efficiency in manufacturing processes, as well as reduced labor costs.

Another important technological advancement in the industry is the development of intelligent control systems. These systems use advanced sensors and software to monitor and adjust the filling and sealing process in real-time, ensuring that each product is filled and sealed to the exact specifications required. This level of precision and control has helped to improve product quality and consistency, leading to higher customer satisfaction and reduced waste.

Advances in materials and design have also had a significant impact on the liquid filling and sealing machine market. New materials and coatings have been developed that are more durable and resistant to corrosion, extending the lifespan of machines and reducing maintenance costs. In addition, new designs and configurations have been introduced that allow for greater flexibility and customization, making it easier for manufacturers to adapt their machines to different products and production requirements.

The integration of digital technologies, such as IoT (Internet of Things) and cloud computing, has further enhanced the capabilities of liquid filling and sealing machines. These technologies allow for remote monitoring and control of machines, as well as the collection and analysis of data to optimize performance and identify potential issues before they become problems. This has helped to improve overall equipment effectiveness and reduce downtime, leading to increased productivity and profitability for manufacturers.

Overall, the impact of technological advancements on the liquid filling and sealing machine market has been overwhelmingly positive. These advancements have not only improved the efficiency and accuracy of machines but have also expanded their capabilities and versatility, making them indispensable tools for manufacturers in a wide range of industries. As technology continues to evolve, we can expect to see even more innovations in the liquid filling and sealing machine market, further driving growth and innovation in the industry.