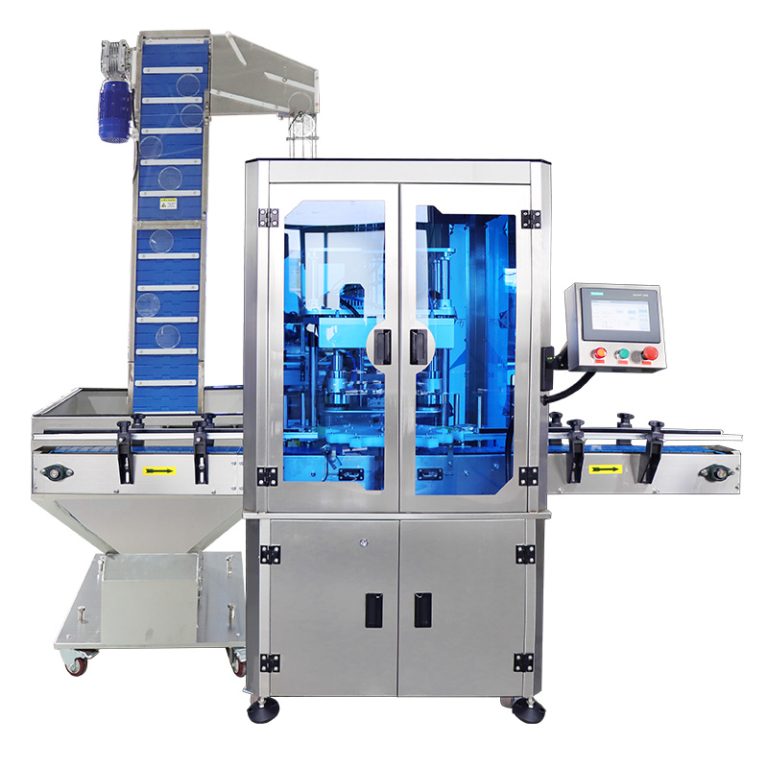

Automatic Double-Head Glass Bottle Vacuum Cappers come with several remarkable features that set them apart in the packaging industry.

One of the key features is the dual-head design. This allows for simultaneous capping of two glass bottles, significantly increasing the production rate and efficiency. It enables businesses to meet higher demands and deadlines with ease.

The vacuum sealing technology is another essential aspect. By creating a vacuum inside the bottles before capping, it ensures a tight and airtight seal. This helps to preserve the quality and freshness of the contents, especially for products that are sensitive to air or moisture.

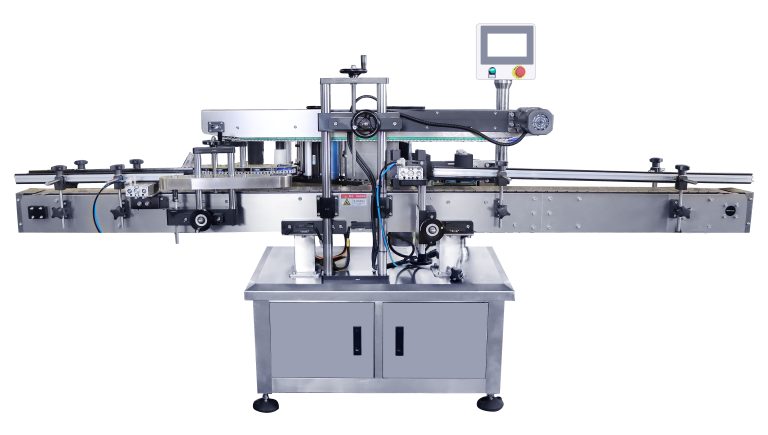

Precision and accuracy are also crucial features. These cappers are equipped with advanced control systems that precisely apply the caps, ensuring consistent and reliable sealing every time. This reduces the risk of leaks or improper seals, enhancing the overall quality of the packaged products.

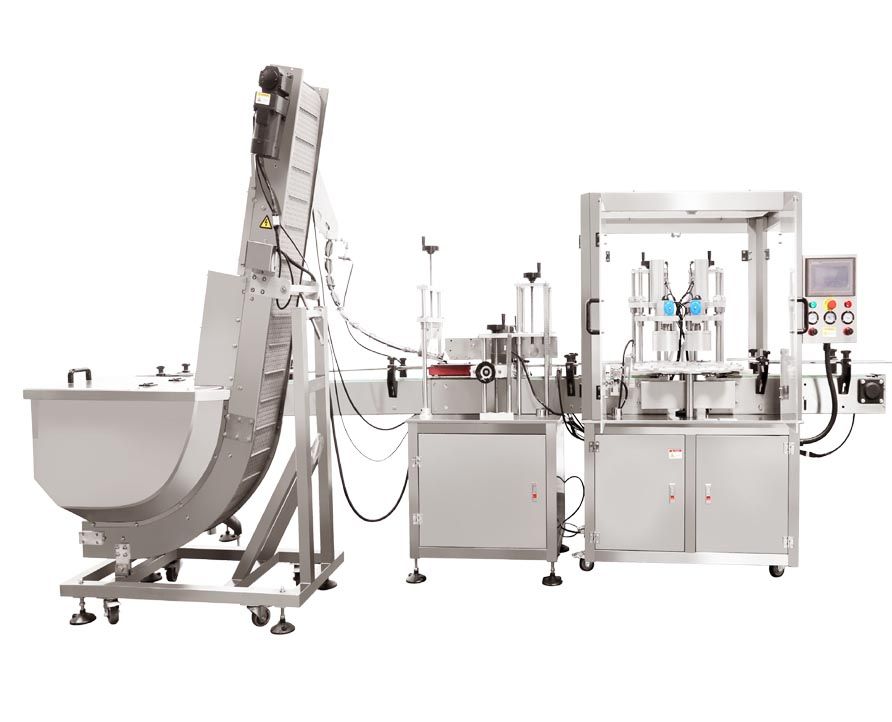

The adaptability of these machines is notable. They can handle a wide range of glass bottle sizes and shapes, as well as different types of caps. This flexibility makes them suitable for various packaging needs and applications.

Furthermore, they often come with user-friendly interfaces and intuitive controls. This simplifies operation and makes it easier for operators to adjust settings and monitor the capping process.

In addition, many Automatic Double-Head Glass Bottle Vacuum Cappers are built with durable materials and components to ensure long-term reliable performance and minimal maintenance requirements.

In conclusion, the combination of these key features makes Automatic Double-Head Glass Bottle Vacuum Cappers a valuable and efficient solution for packaging operations.