Table of Contents

Benefits of Using Automatic Tea Nitrogen Flushing Gas Can Seaming Machine

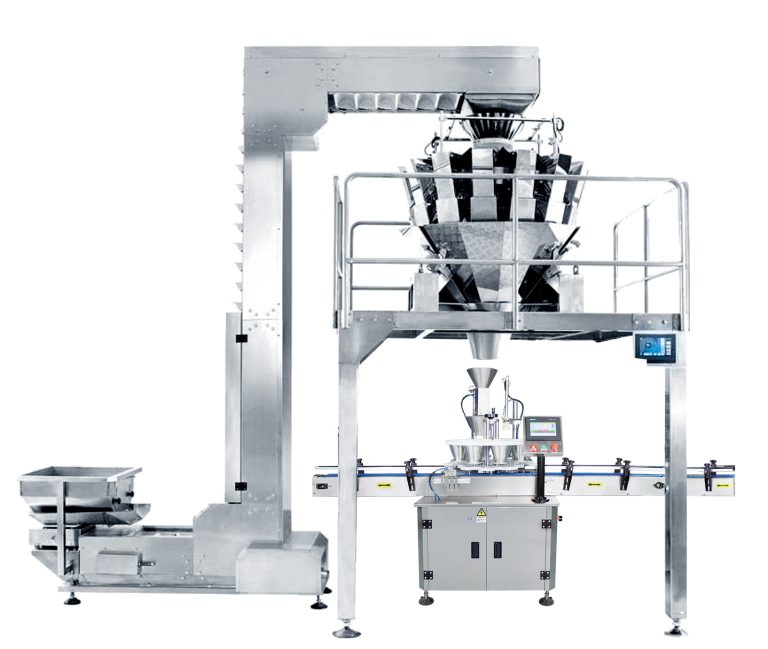

In the world of food packaging, preserving the freshness and quality of products is essential. This is especially true for tea, a delicate and aromatic beverage that can easily lose its flavor if not properly stored. One of the most effective ways to ensure the longevity of tea is through nitrogen flushing, a process that removes oxygen from the packaging to prevent oxidation. When combined with can seaming, which seals the package tightly, the result is a product that stays fresh for longer periods of time. This is where the automatic tea nitrogen flushing gas can seaming machine comes into play.

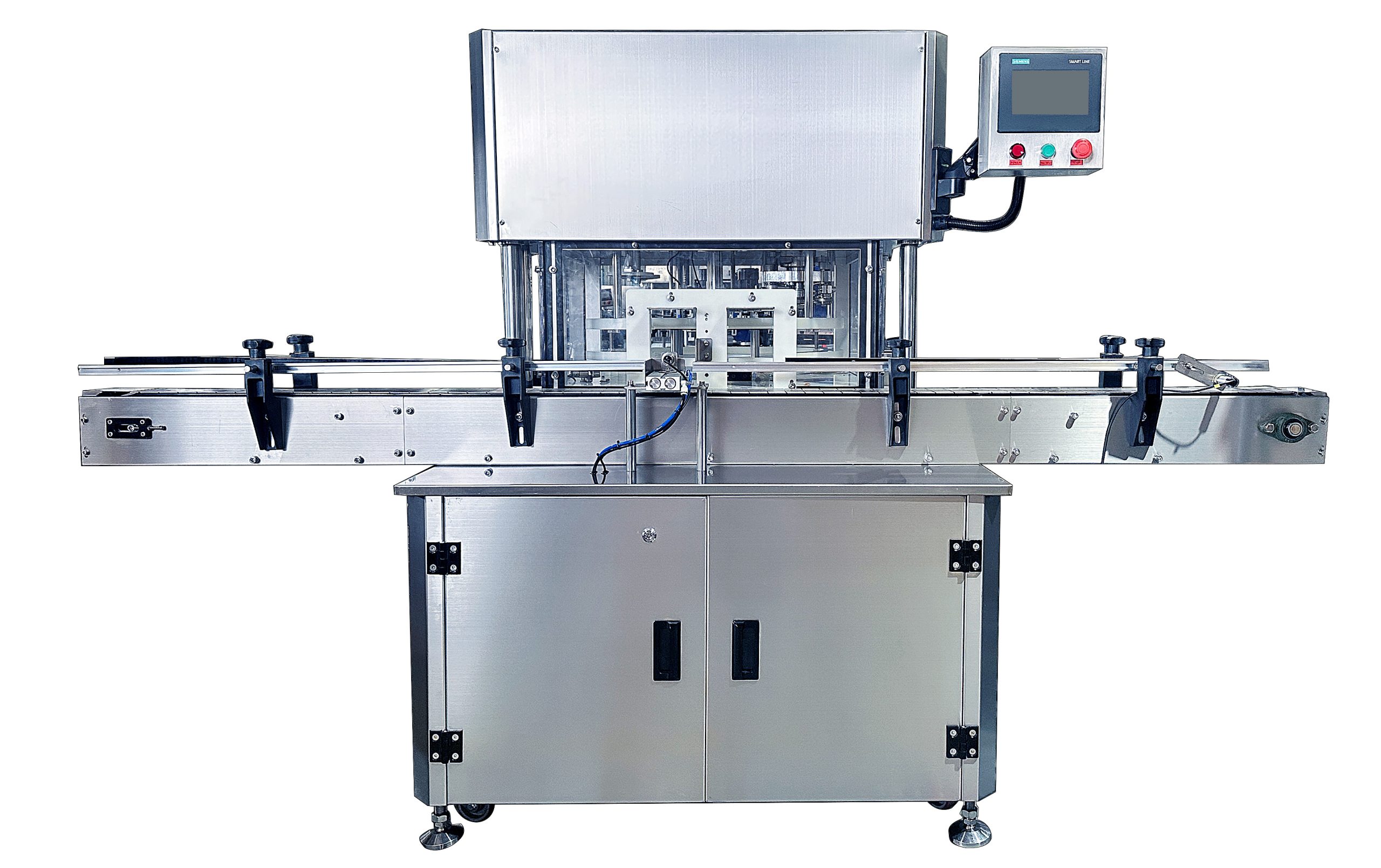

This innovative machine offers a range of benefits for tea producers and consumers alike. Firstly, it streamlines the packaging process, allowing for faster and more efficient production. With the ability to automatically flush nitrogen gas into the cans before sealing them, this machine eliminates the need for manual labor, reducing the risk of human error and ensuring consistency in the packaging process. This not only saves time and labor costs for producers but also guarantees a higher quality product for consumers.

Additionally, the automatic tea nitrogen flushing gas can seaming machine helps to extend the shelf life of tea. By removing oxygen from the packaging, the machine creates an oxygen-free environment that prevents oxidation and preserves the freshness of the tea. This means that consumers can enjoy their favorite teas for longer periods of time without worrying about them losing their flavor or aroma. This is particularly important for premium teas that are often more expensive and sought after for their unique taste profiles.

Furthermore, the nitrogen flushing process helps to protect the tea from external factors that can degrade its quality. By creating a barrier between the tea and the outside environment, the machine shields the product from moisture, light, and other contaminants that can affect its taste and aroma. This ensures that the tea remains in pristine condition from the moment it is packaged until it is consumed, providing a superior drinking experience for consumers.

Another key benefit of the automatic tea nitrogen flushing gas can seaming machine is its versatility. This machine can be used for a wide range of tea products, including loose leaf tea, tea bags, and powdered tea. This flexibility allows producers to package different types of tea with ease, catering to the diverse preferences of consumers. Whether it is a fragrant green tea or a robust black tea, this machine can handle it all, making it a valuable asset for tea producers looking to expand their product offerings.

In conclusion, the automatic tea nitrogen flushing gas can seaming machine offers a host of benefits for both tea producers and consumers. From streamlining the packaging process to extending the shelf life of tea, this machine is a game-changer in the world of food packaging. With its ability to preserve the freshness and quality of tea, while also providing efficiency and versatility, it is a must-have tool for any tea producer looking to deliver a superior product to their customers.

How to Choose the Right Automatic Tea Nitrogen Flushing Gas Can Seaming Machine for Your Business

In the world of tea packaging, the use of automatic tea nitrogen flushing gas can seaming machines has become increasingly popular. These machines are designed to seal cans filled with tea while also flushing out oxygen and replacing it with nitrogen gas to preserve the freshness and quality of the tea. With so many options available on the market, choosing the right automatic tea nitrogen flushing gas can seaming machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting the right machine for your needs.

One of the first things to consider when choosing an automatic tea nitrogen flushing gas can seaming machine is the size and capacity of the machine. You will need to determine how many cans you plan to seal per hour and choose a machine that can handle that volume. It is important to select a machine that is not only capable of meeting your current production needs but also has the capacity to grow with your business in the future.

Another important factor to consider is the level of automation that the machine offers. Some machines are fully automatic, meaning they require minimal human intervention, while others may require more manual operation. Depending on your production requirements and budget, you will need to decide which level of automation is right for your business.

In addition to size and automation, it is also important to consider the quality and reliability of the machine. Look for a machine that is made from high-quality materials and is built to last. You will want a machine that can withstand the rigors of daily use and continue to perform at a high level for years to come. It is also a good idea to read reviews and testimonials from other users to get an idea of the machine’s performance and reliability.

Cost is another important factor to consider when choosing an automatic tea nitrogen flushing gas can seaming machine. While it is important to stay within your budget, it is also important to remember that quality and reliability should not be sacrificed for a lower price. Look for a machine that offers the best value for your money and provides the features and capabilities that you need to run your business efficiently.

When selecting an automatic tea nitrogen flushing gas can seaming machine, it is also important to consider the level of customer support and service that the manufacturer provides. Look for a company that offers comprehensive training and support to help you get the most out of your machine. It is also a good idea to choose a manufacturer that offers a warranty on their products to protect your investment.

In conclusion, choosing the right automatic tea nitrogen flushing gas can seaming machine for your business is a decision that should not be taken lightly. Consider factors such as size, capacity, automation, quality, reliability, cost, and customer support when making your decision. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure that your tea packaging operation runs smoothly and efficiently for years to come.

Maintenance Tips for Automatic Tea Nitrogen Flushing Gas Can Seaming Machine

Maintaining an automatic tea nitrogen flushing gas can seaming machine is essential to ensure its optimal performance and longevity. Regular maintenance not only helps prevent breakdowns and costly repairs but also ensures that the machine operates efficiently, producing high-quality sealed cans of tea. In this article, we will discuss some important maintenance tips for automatic tea nitrogen flushing gas can seaming machines.

One of the most important maintenance tasks for an automatic tea nitrogen flushing gas can seaming machine is cleaning. Regular cleaning of the machine helps prevent the buildup of dirt, dust, and other debris that can affect its performance. It is recommended to clean the machine after each use to remove any residue or particles that may have accumulated during the sealing process. Use a soft cloth or brush to gently clean the machine, paying special attention to the seaming rollers and other moving parts.

In addition to regular cleaning, it is important to lubricate the moving parts of the machine to ensure smooth operation. Lubrication helps reduce friction between the parts, preventing wear and tear and extending the life of the machine. Use a high-quality lubricant recommended by the manufacturer and apply it to the moving parts according to the manufacturer’s instructions. Be sure to lubricate the machine regularly to keep it running smoothly.

Another important maintenance task for automatic tea nitrogen flushing gas can seaming machines is inspecting the machine for any signs of wear or damage. Check the seaming rollers, can guides, and other components for any signs of wear, such as cracks, dents, or corrosion. Replace any damaged parts immediately to prevent further damage to the machine and ensure its proper functioning. Regular inspections can help identify potential issues before they escalate into major problems.

It is also important to calibrate the machine regularly to ensure accurate sealing of the cans. Calibration helps maintain the proper pressure, temperature, and other settings required for sealing the cans effectively. Follow the manufacturer’s guidelines for calibrating the machine and perform this task regularly to ensure consistent and reliable sealing of the cans.

In addition to these maintenance tasks, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic tea nitrogen flushing gas can seaming machine. This schedule may include tasks such as replacing worn parts, checking the electrical connections, and performing other routine maintenance procedures. By following the manufacturer’s guidelines, you can ensure that your machine operates at its best and produces high-quality sealed cans of tea.

In conclusion, regular maintenance is essential for automatic tea nitrogen flushing gas can seaming machines to ensure their optimal performance and longevity. By following the maintenance tips outlined in this article, you can keep your machine running smoothly and producing high-quality sealed cans of tea. Remember to clean the machine regularly, lubricate the moving parts, inspect for wear or damage, calibrate the machine, and follow the manufacturer’s recommended maintenance schedule. With proper maintenance, your automatic tea nitrogen flushing gas can seaming machine will continue to operate efficiently and effectively for years to come.