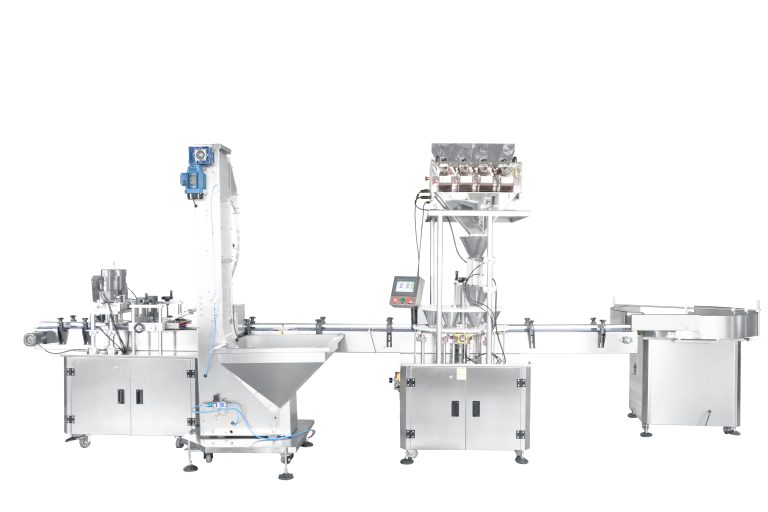

In the realm of medical manufacturing, the fully automatic medical powder auger filling machine has emerged as a game-changer. This sophisticated piece of equipment is specifically engineered to meet the rigorous demands of filling medical powders with accuracy and consistency.

One of the most significant advantages of this machine is its high level of automation. It operates with minimal human intervention, reducing the potential for errors and ensuring a seamless filling process. The auger mechanism precisely measures and dispenses the powder, guaranteeing each container receives the exact dosage prescribed.

The fully automatic medical powder auger filling machine is designed to adhere to strict hygiene and quality standards. Materials used in its construction are non-reactive and easy to clean, preventing any contamination of the medical powder. This is crucial in maintaining the purity and efficacy of the final product.

It also offers remarkable speed and efficiency. The ability to fill a large number of containers in a short period is essential in meeting the high production demands of the medical industry. At the same time, it doesn’t compromise on accuracy, ensuring that every batch is filled to perfection.

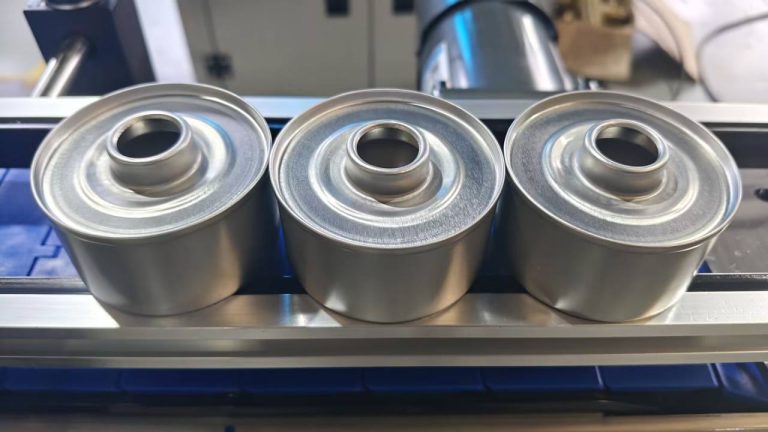

The fully automatic medical powder auger filling machine is highly customizable. It can be adjusted to handle different powder consistencies, container sizes, and filling volumes, providing flexibility for various medical formulations.

Advanced control systems and sensors monitor the filling process in real-time. Any deviations from the set parameters are immediately detected and corrected, ensuring that every container meets the strict quality control standards of the medical sector.

Investing in this fully automatic medical powder auger filling machine is not only a step towards enhanced productivity but also a commitment to patient safety and the integrity of medical products.

Stay updated with the latest in medical packaging technology by following our blogs!