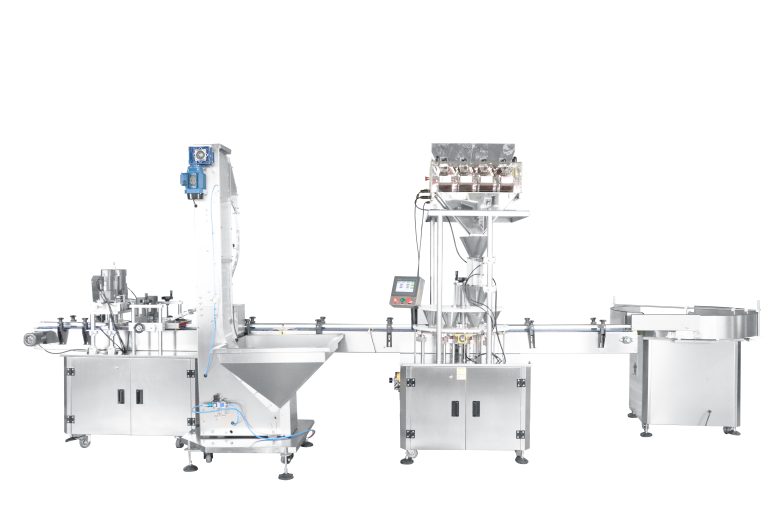

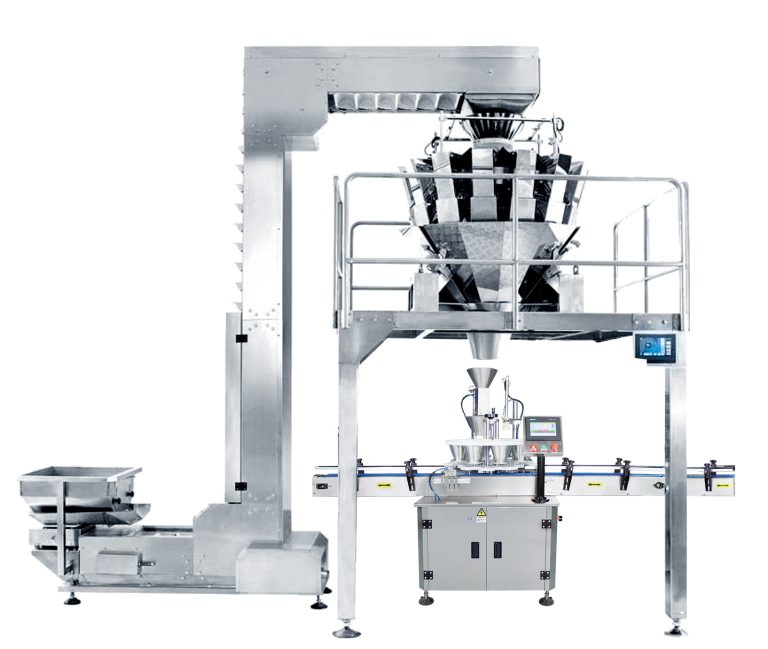

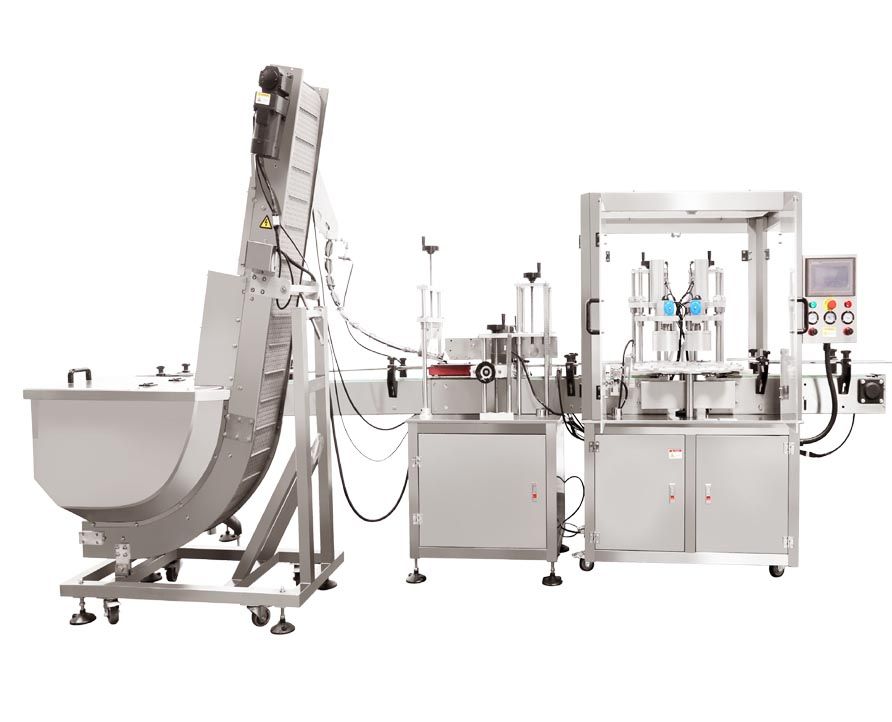

In the world of almond butter production, the automatic almond butter glass bottle vacuum capping machine is a game-changer. This advanced piece of equipment is specifically designed to ensure the highest level of preservation and presentation for almond butter in glass bottles.

One of the key benefits of this vacuum capping machine is its ability to create an airtight seal. By removing the air from inside the bottle, it helps prevent oxidation and spoilage, allowing the almond butter to maintain its fresh flavor and texture for an extended period.

The automatic operation of the machine ensures consistent and accurate capping every time. This eliminates the potential for human error and guarantees that each bottle is sealed to the same high standard. The precision of the sealing process also enhances the overall appearance of the packaged product, making it more appealing to consumers on store shelves.

The machine is engineered to handle glass bottles of various sizes and shapes, providing flexibility for manufacturers. It can adapt to different production volumes, making it suitable for both small-scale artisanal producers and larger industrial operations.

The use of vacuum capping technology not only preserves the quality of the almond butter but also helps to extend its shelf life. This is a significant advantage for both manufacturers and distributors, as it reduces the risk of product spoilage and waste.

Maintenance of the automatic almond butter glass bottle vacuum capping machine is relatively straightforward. Regular cleaning and inspection of key components ensure its continued reliable performance and longevity.

In conclusion, the aautomatic almond butter glass bottle vacuum capping machine is an essential tool for the almond butter industry. It combines efficiency, quality, and functionality to deliver a superior packaged product that meets the expectations of consumers and the demands of the market.

Stay tuned to our blogs for more detailed insights and updates on the latest advancements in food packaging machinery!