Table of Contents

Automation in Can Packaging Line

In the world of manufacturing, efficiency is key. This is especially true in the can packaging industry, where every second counts in getting products out the door and into the hands of consumers. One way to improve efficiency in a can packaging line is through automation. By implementing automated systems and processes, companies can streamline their operations, reduce labor costs, and increase overall productivity.

One of the first steps in improving can packaging line efficiency through automation is to assess the current state of the line. This involves looking at each step in the packaging process, from filling and sealing cans to labeling and palletizing. By identifying areas where bottlenecks occur or where manual labor is slowing down the process, companies can pinpoint where automation can make the biggest impact.

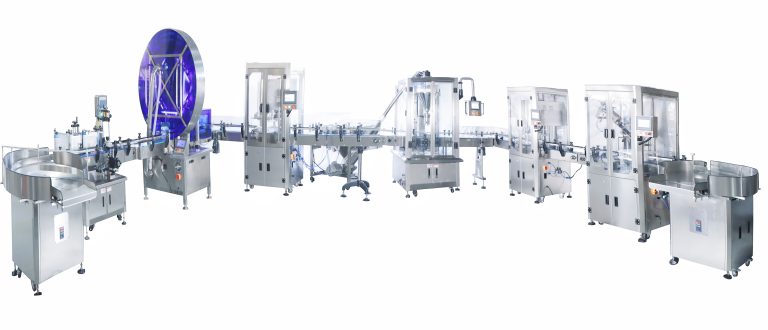

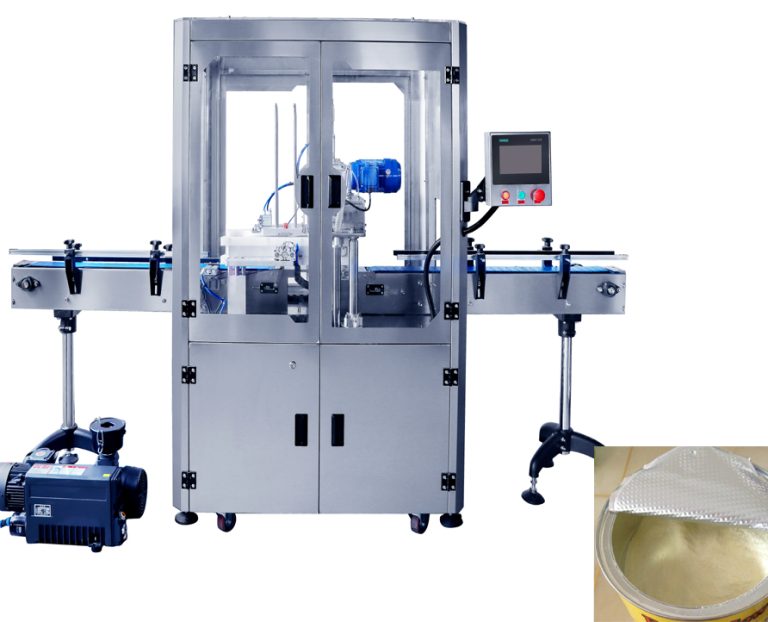

Once areas for improvement have been identified, companies can begin to implement automated solutions. This can include installing robotic arms to handle tasks such as picking and placing cans, or using conveyor systems to transport cans from one part of the line to another. By automating these tasks, companies can reduce the risk of human error and increase the speed at which products are packaged and shipped.

Another way to improve can packaging line efficiency through automation is by implementing software systems that can monitor and control the entire packaging process. These systems can track the flow of cans through the line, alerting operators to any issues that may arise and providing real-time data on line performance. By having this information at their fingertips, companies can make quick adjustments to the line to keep it running smoothly and efficiently.

In addition to improving efficiency, automation in can packaging lines can also help companies reduce costs. By reducing the need for manual labor, companies can lower their labor costs and reallocate resources to other areas of the business. Automation can also help companies reduce waste by ensuring that products are packaged correctly the first time, reducing the need for rework or scrap.

Overall, automation in can packaging lines can have a significant impact on a company’s bottom line. By streamlining operations, reducing labor costs, and increasing productivity, companies can improve their competitiveness in the market and better meet the demands of consumers. As technology continues to advance, companies that invest in automation will be better positioned to succeed in the fast-paced world of manufacturing.

In conclusion, improving can packaging line efficiency through automation is a smart investment for companies looking to stay ahead in the competitive packaging industry. By assessing current processes, implementing automated solutions, and monitoring performance, companies can streamline their operations, reduce costs, and increase productivity. Automation is the future of manufacturing, and companies that embrace it will be well-positioned for success in the years to come.

Lean Manufacturing Principles in Can Packaging Line

In the world of manufacturing, efficiency is key. This is especially true in the can packaging industry, where every second counts in getting products out the door and into the hands of consumers. Improving the efficiency of your can packaging line can have a significant impact on your bottom line, as well as on the overall quality of your products. By implementing lean manufacturing principles, you can streamline your processes, reduce waste, and increase productivity.

One of the first steps in improving the efficiency of your can packaging line is to analyze your current processes. Take a close look at each step in the packaging process, from filling the cans to sealing them and labeling them for shipment. Identify any bottlenecks or inefficiencies that are slowing down your production line. Once you have a clear understanding of where improvements can be made, you can begin to implement changes that will help to streamline your processes.

One of the key principles of lean manufacturing is to eliminate waste. This can include anything from excess inventory to unnecessary movements on the production line. By reducing waste in your packaging processes, you can improve efficiency and reduce costs. Look for ways to optimize your workflow, such as by reorganizing workstations or implementing automated systems that can help to speed up production.

Another important aspect of improving efficiency in your can packaging line is to standardize your processes. By creating standardized work instructions and procedures, you can ensure that every employee is following the same steps and using the same techniques to package your products. This can help to reduce errors and inconsistencies in your packaging process, leading to higher quality products and faster production times.

In addition to standardizing your processes, it is also important to empower your employees to make improvements to the packaging line. Encourage them to identify areas where efficiency can be improved and to suggest solutions for making those improvements. By involving your employees in the process of improving efficiency, you can tap into their knowledge and experience to help make your packaging line more streamlined and effective.

One of the key principles of lean manufacturing is continuous improvement. This means that you should always be looking for ways to make your packaging line more efficient, even after you have implemented initial changes. Regularly review your processes and look for opportunities to make further improvements. This could involve investing in new technology, reorganizing workstations, or implementing new training programs for your employees.

By implementing lean manufacturing principles in your can packaging line, you can improve efficiency, reduce waste, and increase productivity. By analyzing your current processes, eliminating waste, standardizing your procedures, empowering your employees, and continuously improving your processes, you can create a more streamlined and effective packaging line that will help to drive your business forward. By focusing on efficiency and quality in your packaging processes, you can ensure that your products are delivered to consumers in a timely manner and meet the highest standards of quality.