Table of Contents

Benefits of Investing in a High-Quality Can Packaging Production Line

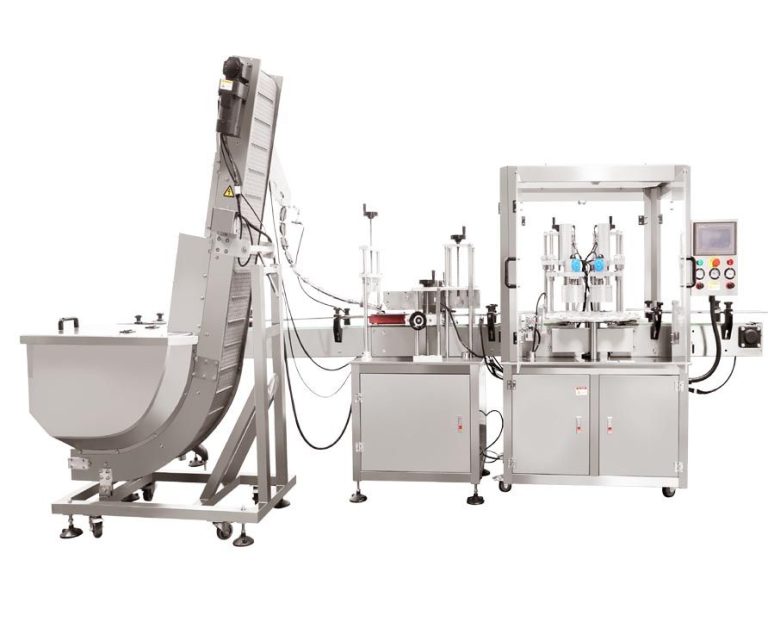

When it comes to packaging products in cans, having an efficient and high-quality can packaging production line is essential for businesses looking to streamline their operations and ensure the quality of their products. Investing in a high-quality can packaging production line can offer a range of benefits, from increased productivity and efficiency to improved product quality and reduced waste. In this article, we will explore the benefits of investing in a high-quality can packaging production line and provide some tips on how to choose the right one for your business.

One of the key benefits of investing in a high-quality can packaging production line is increased productivity. A high-quality production line can help to automate many of the packaging processes, reducing the need for manual labor and speeding up the production process. This can help businesses to increase their output and meet customer demand more efficiently, ultimately leading to higher profits and a more competitive edge in the market.

In addition to increased productivity, a high-quality can packaging production line can also help to improve product quality. By automating the packaging process, businesses can ensure that each can is filled and sealed correctly, reducing the risk of errors and defects. This can help to improve the overall quality of the products being packaged, leading to higher customer satisfaction and repeat business.

Another benefit of investing in a high-quality can packaging production line is reduced waste. By automating the packaging process and reducing the risk of errors, businesses can minimize the amount of product that is wasted due to packaging defects or mistakes. This can help to improve the overall efficiency of the production process and reduce costs associated with waste disposal.

When choosing a can packaging production line for your business, there are a few key factors to consider. First and foremost, it is important to choose a production line that is efficient and reliable. Look for a production line that is designed to handle the specific needs of your business, whether that be high-speed production or specialized packaging requirements.

It is also important to consider the quality of the production line and the reputation of the manufacturer. Look for a production line that is made from high-quality materials and components, and choose a manufacturer with a track record of producing reliable and durable equipment. Investing in a high-quality production line may require a larger upfront investment, but the long-term benefits in terms of increased productivity, improved product quality, and reduced waste can far outweigh the initial cost.

In conclusion, investing in a high-quality can packaging production line can offer a range of benefits for businesses looking to streamline their operations and improve the quality of their products. By choosing a production line that is efficient, reliable, and made from high-quality materials, businesses can increase productivity, improve product quality, and reduce waste. When considering a can packaging production line for your business, be sure to carefully evaluate your needs and choose a production line that is tailored to meet those needs. With the right production line in place, businesses can enjoy increased efficiency, improved product quality, and a more competitive edge in the market.

Key Factors to Consider When Choosing an Efficient Can Packaging Production Line

When it comes to choosing a can packaging production line for your business, there are several key factors to consider in order to ensure that you are selecting an efficient and high-quality system. The packaging process is a critical component of any manufacturing operation, as it directly impacts the speed, accuracy, and overall quality of the final product. By carefully evaluating these key factors, you can make an informed decision that will benefit your business in the long run.

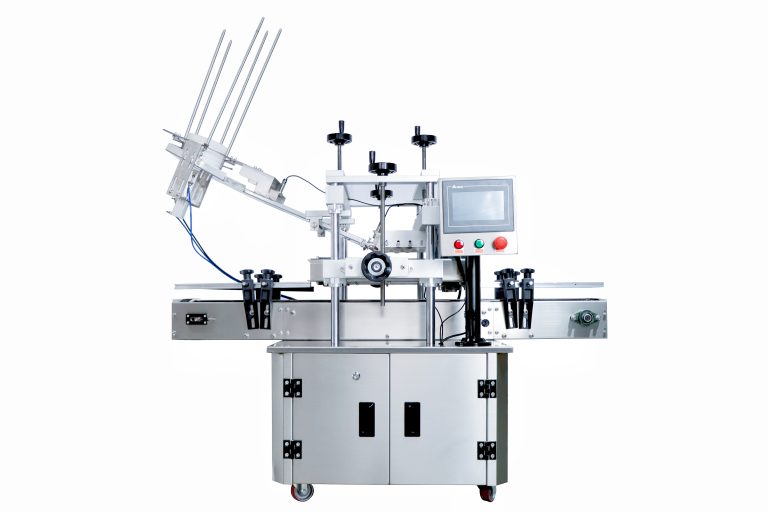

One of the first factors to consider when choosing a can packaging production line is the speed and efficiency of the system. The production line should be able to handle the volume of cans that your business requires, while also maintaining a high level of speed and accuracy. A slow or inefficient system can lead to bottlenecks in the production process, causing delays and potentially impacting the quality of the final product. Look for a production line that is designed to maximize efficiency and minimize downtime, in order to keep your operations running smoothly.

Another important factor to consider is the quality of the packaging materials used in the production line. The packaging materials should be durable, reliable, and able to withstand the rigors of the packaging process. Low-quality materials can lead to damaged or compromised cans, which can result in product waste and loss of revenue. Choose a production line that uses high-quality materials and components, in order to ensure that your cans are packaged securely and safely.

In addition to speed and quality, it is also important to consider the flexibility and versatility of the can packaging production line. The system should be able to accommodate a variety of can sizes and shapes, in order to meet the diverse needs of your business. A flexible production line can adapt to changing production requirements and allow for easy customization of packaging options. Look for a system that offers modular components and adjustable settings, in order to maximize the versatility of the production line.

Cost is another key factor to consider when choosing a can packaging production line. While it is important to invest in a high-quality system, it is also essential to consider the overall cost of the system and its long-term value to your business. Compare the upfront costs of different production lines, as well as the ongoing maintenance and operating expenses. Look for a system that offers a good balance of quality and affordability, in order to maximize the return on your investment.

Finally, consider the reputation and track record of the manufacturer when choosing a can packaging production line. Look for a manufacturer with a proven history of producing high-quality packaging systems, and check for customer reviews and testimonials to gauge the satisfaction of previous clients. A reputable manufacturer will stand behind their products and provide excellent customer support, in order to ensure that your production line operates smoothly and efficiently.

In conclusion, choosing an efficient and high-quality can packaging production line is a critical decision for any business. By carefully evaluating key factors such as speed, quality, flexibility, cost, and manufacturer reputation, you can select a system that meets your production needs and delivers long-term value to your business. Take the time to research and compare different options, in order to make an informed decision that will benefit your operations in the long run.

Top Features to Look for in a High-Quality Can Packaging Production Line

When it comes to choosing a can packaging production line for your business, there are several key features that you should look for to ensure that you are getting a high-quality and efficient machine. Investing in the right packaging equipment can make a significant difference in the productivity and profitability of your operation. In this article, we will discuss some of the top features to look for in a high-quality can packaging production line.

One of the most important features to consider when choosing a can packaging production line is the speed and efficiency of the machine. A high-quality production line should be able to handle a large volume of cans quickly and accurately. Look for a machine that has a high production rate and can keep up with the demands of your business. Additionally, the machine should be able to operate efficiently without frequent breakdowns or maintenance issues.

Another important feature to consider is the versatility of the can packaging production line. The machine should be able to handle a variety of can sizes and shapes, as well as different types of packaging materials. This will allow you to adapt to changing market demands and offer a wider range of products to your customers. Look for a machine that can be easily adjusted to accommodate different can sizes and packaging configurations.

Durability and reliability are also key features to look for in a high-quality can packaging production line. The machine should be built to last and able to withstand the rigors of continuous use in a production environment. Look for a machine that is made from high-quality materials and has a solid construction. Additionally, the machine should be backed by a reliable manufacturer with a good reputation for customer service and support.

Ease of use and maintenance is another important factor to consider when choosing a can packaging production line. The machine should be user-friendly and easy to operate, with intuitive controls and clear instructions. Additionally, the machine should be easy to clean and maintain, with accessible components that can be easily replaced or repaired if necessary. Look for a machine that comes with comprehensive training and support to ensure that your operators can use it effectively.

Finally, consider the overall cost of the can packaging production line, including the initial purchase price, installation costs, and ongoing maintenance expenses. While it is important to invest in a high-quality machine, you should also consider the long-term return on investment and the total cost of ownership. Look for a machine that offers good value for money and can help you improve efficiency and reduce waste in your packaging process.

In conclusion, choosing a high-quality can packaging production line is a critical decision for any business that relies on efficient and reliable packaging equipment. By considering the key features discussed in this article, you can select a machine that meets your needs and helps you achieve your production goals. Invest in a high-quality can packaging production line today and take your packaging operation to the next level.