Table of Contents

Increased Efficiency

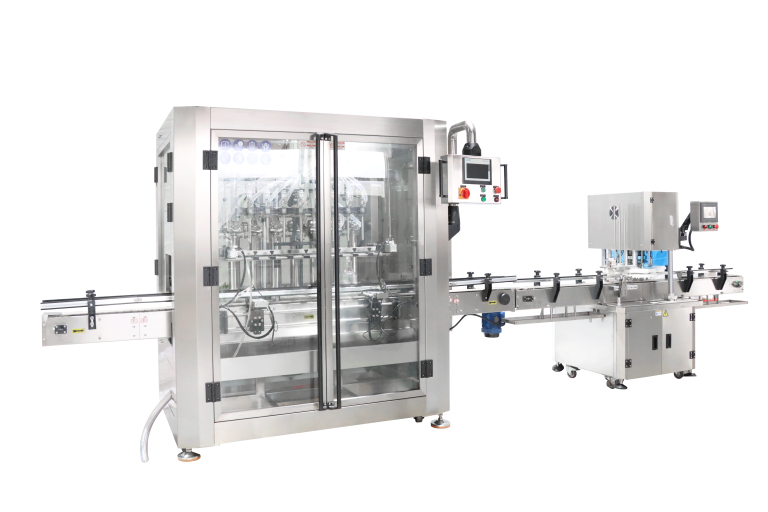

Milk powder filling machines are a valuable asset for any production line looking to increase efficiency and streamline operations. These machines are designed to accurately fill containers with powdered milk, reducing the risk of human error and ensuring consistent product quality. By automating the filling process, companies can save time and resources while also improving overall productivity.

One of the key benefits of using milk powder filling machines is the speed at which they can fill containers. These machines are capable of filling hundreds of containers per minute, far surpassing the speed at which a human operator could fill them manually. This increased speed not only allows for higher production volumes but also helps to reduce bottlenecks in the production line, leading to a more efficient overall process.

In addition to speed, milk powder filling machines also offer a high level of accuracy in filling containers. These machines are equipped with precision measuring systems that ensure each container is filled to the exact specifications required. This level of accuracy helps to minimize product waste and ensures that customers receive consistent and high-quality products every time.

Furthermore, milk powder filling machines are designed to be easy to operate and maintain. Many machines come with user-friendly interfaces that allow operators to quickly set up and adjust filling parameters as needed. Additionally, these machines are built to withstand the rigors of continuous use, reducing the likelihood of breakdowns and costly downtime.

By incorporating milk powder filling machines into their production lines, companies can also improve overall safety and hygiene standards. These machines are typically made from stainless steel, which is easy to clean and sanitize, reducing the risk of contamination. Additionally, the automated nature of these machines means that there is less direct contact with the product, further reducing the risk of contamination and ensuring a safer working environment for employees.

Overall, milk powder filling machines offer a wide range of benefits for companies looking to improve their production lines. From increased speed and accuracy to improved safety and hygiene standards, these machines can help companies save time and resources while also ensuring consistent product quality. By investing in a milk powder filling machine, companies can streamline their operations, increase efficiency, and ultimately improve their bottom line.

In conclusion, milk powder filling machines are a valuable asset for any production line looking to improve efficiency and productivity. These machines offer a range of benefits, including increased speed and accuracy, improved safety and hygiene standards, and ease of operation and maintenance. By incorporating a milk powder filling machine into their production line, companies can save time and resources while also ensuring consistent product quality. Ultimately, investing in a milk powder filling machine can help companies stay competitive in today’s fast-paced market and drive success in the long term.

Cost Savings

Milk powder filling machines are a valuable asset for any production line in the dairy industry. These machines are designed to efficiently and accurately fill containers with powdered milk, reducing the risk of human error and ensuring consistent product quality. In addition to improving the overall efficiency of the production process, milk powder filling machines can also help companies save money in the long run.

One of the primary ways in which milk powder filling machines can help companies save money is by reducing product waste. When filling containers manually, there is a higher risk of overfilling or underfilling, which can result in product being wasted. By using a milk powder filling machine, companies can ensure that each container is filled with the exact amount of product required, minimizing waste and maximizing product yield.

Furthermore, milk powder filling machines can also help companies save money by increasing production speed. These machines are designed to fill containers quickly and accurately, allowing companies to produce more product in a shorter amount of time. This increased production speed can help companies meet customer demand more efficiently, leading to higher sales and increased revenue.

In addition to reducing product waste and increasing production speed, milk powder filling machines can also help companies save money by reducing labor costs. When filling containers manually, companies must employ workers to perform this task, which can be time-consuming and costly. By using a milk powder filling machine, companies can automate the filling process, reducing the need for manual labor and saving money on labor costs.

Overall, milk powder filling machines are a cost-effective solution for companies in the dairy industry looking to improve their production line. By reducing product waste, increasing production speed, and minimizing labor costs, these machines can help companies save money and increase their bottom line. Investing in a milk powder filling machine is a smart decision for any company looking to improve efficiency and profitability in their production process.

Consistent Quality

Milk powder filling machines are a crucial component in the production line of dairy products. These machines play a significant role in ensuring consistent quality and efficiency in the manufacturing process. By automating the filling process, milk powder filling machines can help improve the overall productivity of a production line.

One of the key benefits of using milk powder filling machines is the ability to maintain consistent quality in the final product. These machines are designed to accurately measure and dispense the correct amount of milk powder into each package, ensuring that every product meets the same high standards. This level of precision is difficult to achieve with manual filling methods, which can lead to variations in product quality.

In addition to maintaining consistent quality, milk powder filling machines can also help improve the efficiency of a production line. These machines are capable of filling a large number of packages in a short amount of time, reducing the need for manual labor and increasing overall output. This can result in cost savings for manufacturers, as well as faster turnaround times for customers.

Another advantage of using milk powder filling machines is the ability to reduce waste. By accurately measuring and dispensing the correct amount of milk powder, these machines can help minimize product overfill and spillage. This not only saves money for manufacturers but also helps reduce the environmental impact of the production process.

Furthermore, milk powder filling machines are designed to be easy to operate and maintain. Most machines come with user-friendly interfaces and can be easily adjusted to accommodate different package sizes and production requirements. This makes it simple for operators to quickly set up the machine and start filling packages, without the need for extensive training or technical expertise.

Additionally, milk powder filling machines are built to be durable and reliable, ensuring consistent performance over time. This can help manufacturers avoid costly downtime and repairs, allowing them to keep their production line running smoothly and efficiently.

Overall, milk powder filling machines offer a range of benefits for manufacturers looking to improve the quality and efficiency of their production line. By automating the filling process, these machines can help ensure consistent quality, increase productivity, reduce waste, and streamline operations. With their user-friendly design and reliable performance, milk powder filling machines are a valuable investment for any dairy product manufacturer looking to enhance their production capabilities.