Table of Contents

Benefits of Using Powder Filling Machines in Manufacturing Processes

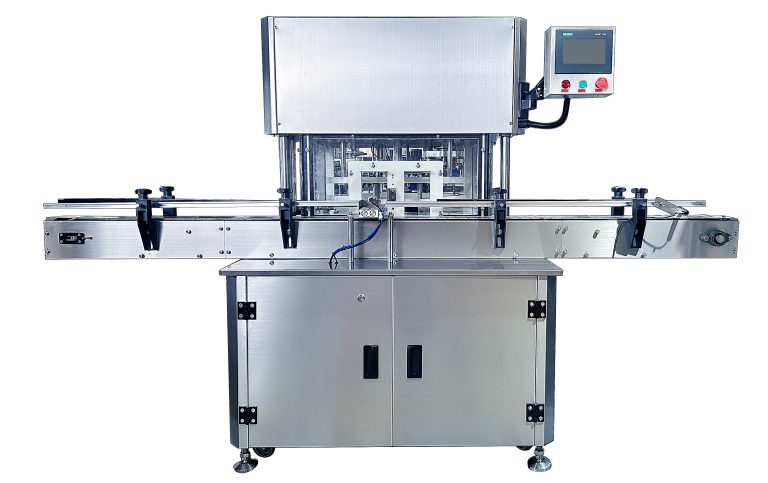

Powder filling machines and sealing machines are essential tools in the manufacturing industry, particularly for companies that deal with powdered products. These machines play a crucial role in ensuring efficiency, accuracy, and consistency in the production process. In this article, we will explore the benefits of using powder filling machines in manufacturing processes and how they work in conjunction with sealing machines to deliver high-quality products.

One of the primary advantages of using powder filling machines is their ability to automate the filling process. Manual filling can be time-consuming and prone to errors, leading to inconsistencies in product quality. Powder filling machines, on the other hand, are designed to accurately measure and dispense the desired amount of powder into containers, ensuring uniformity across all products. This not only saves time but also reduces waste and improves overall productivity.

Another benefit of powder filling machines is their versatility. These machines can handle a wide range of powdered products, from fine powders to granules, making them suitable for various industries such as pharmaceuticals, food and beverage, and cosmetics. Additionally, powder filling machines can be customized to accommodate different container sizes and shapes, allowing manufacturers to meet the specific requirements of their products.

In terms of operation, powder filling machines work by feeding the powder into a hopper, which then dispenses the powder into containers through a filling nozzle. The machine is equipped with sensors and controls that regulate the flow of powder, ensuring accurate filling. Some powder filling machines also come with features such as dust extraction systems to maintain a clean working environment.

Sealing machines are another essential component in the manufacturing process, as they ensure that the products are securely sealed to prevent contamination and maintain product freshness. These machines come in various types, including induction sealers, vacuum sealers, and heat sealers, each suited for different packaging requirements.

Induction sealers, for example, use electromagnetic induction to create a hermetic seal on containers with foil liners. This method is commonly used for sealing bottles and jars containing liquids or powders. Vacuum sealers, on the other hand, remove air from the packaging before sealing it, extending the shelf life of perishable products. Heat sealers use heat to melt the packaging material, creating a tight seal that is resistant to tampering.

When used in conjunction with powder filling machines, sealing machines ensure that the products are securely packaged and ready for distribution. By automating the sealing process, manufacturers can increase efficiency and reduce the risk of human error. Additionally, sealed products are less susceptible to damage during transportation, ensuring that they reach consumers in optimal condition.

In conclusion, powder filling machines and sealing machines are indispensable tools in the manufacturing industry, offering numerous benefits such as automation, accuracy, and versatility. By investing in these machines, manufacturers can streamline their production processes, improve product quality, and enhance overall efficiency. Whether you are in the pharmaceutical, food and beverage, or cosmetics industry, incorporating powder filling and sealing machines into your manufacturing process can help you stay ahead of the competition and deliver high-quality products to your customers.

Step-by-Step Guide to Understanding the Functionality of Sealing Machines

Powder filling machines and sealing machines are essential pieces of equipment in various industries, including food, pharmaceuticals, and cosmetics. These machines play a crucial role in packaging products efficiently and effectively. Understanding how these machines work can help businesses improve their production processes and ensure the quality of their products. In this article, we will provide a step-by-step guide to understanding the functionality of sealing machines.

Sealing machines are used to create airtight seals on packaging materials, such as bags, pouches, and containers. These machines come in different types, including heat sealers, induction sealers, and vacuum sealers. Each type of sealing machine operates differently, but they all serve the same purpose of sealing products securely.

The first step in the sealing process is to prepare the packaging material. This may involve filling the bags or pouches with the product, ensuring that they are properly sealed, and placing them on the sealing machine. Once the packaging material is ready, the sealing machine is activated.

The sealing machine uses heat, pressure, or a combination of both to create a seal on the packaging material. Heat sealers, for example, use heat to melt the packaging material and create a bond between the layers. Induction sealers use electromagnetic induction to heat a foil liner, which then bonds to the container. Vacuum sealers remove air from the packaging material before sealing it, creating a vacuum seal.

As the sealing machine operates, it applies the necessary heat, pressure, or vacuum to the packaging material to create a secure seal. The sealing process may take a few seconds to a few minutes, depending on the type of machine and the size of the packaging material. Once the seal is complete, the packaging material is removed from the machine and inspected for quality.

Sealing machines are designed to be efficient and reliable, ensuring that products are sealed properly every time. These machines are equipped with sensors and controls to monitor the sealing process and make adjustments as needed. Some sealing machines also have features such as automatic shut-off and temperature control to prevent overheating and ensure consistent sealing.

In conclusion, sealing machines play a vital role in the packaging industry by creating airtight seals on products. Understanding how these machines work can help businesses improve their production processes and ensure the quality of their products. By following this step-by-step guide to the functionality of sealing machines, businesses can make informed decisions about which type of machine is best suited for their needs. Whether using heat sealers, induction sealers, or vacuum sealers, businesses can rely on sealing machines to seal their products securely and efficiently.