Table of Contents

Benefits of Investing in a Fully Automatic Juice Aluminum Can Filling and Seaming Machine

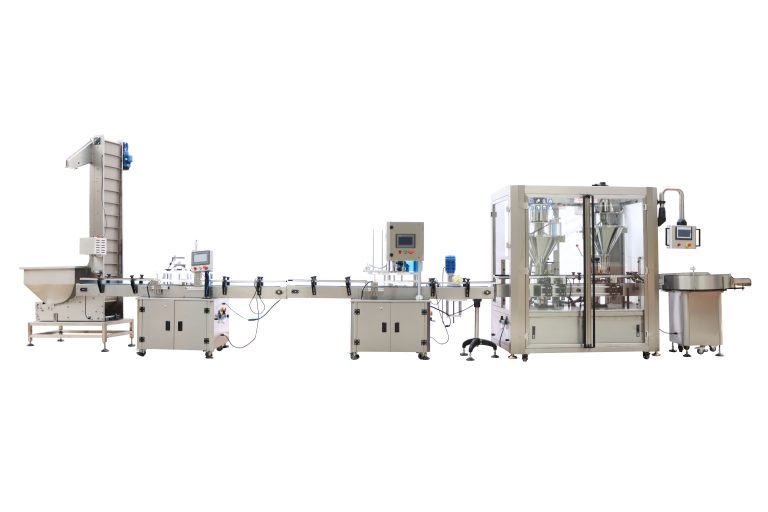

In the world of beverage production, efficiency and consistency are key factors in ensuring a successful operation. One piece of equipment that can greatly enhance these aspects is a fully automatic juice aluminum can filling and seaming machine. This advanced machine is designed to streamline the process of filling and sealing aluminum cans with juice, providing numerous benefits to manufacturers who invest in this technology.

One of the primary benefits of a fully automatic juice aluminum can filling and seaming machine is its ability to increase production output. By automating the filling and sealing process, this machine can significantly reduce the time and labor required to package juice in aluminum cans. This means that manufacturers can produce a larger volume of product in a shorter amount of time, ultimately leading to increased efficiency and profitability.

Additionally, a fully automatic juice aluminum can filling and seaming machine can improve the overall quality and consistency of the finished product. Manual filling and sealing processes are prone to human error, which can result in inconsistencies in the fill level and seal integrity of the cans. By using an automated machine, manufacturers can ensure that each can is filled to the exact same level and sealed with precision, resulting in a more uniform and professional-looking product.

Furthermore, investing in a fully automatic juice aluminum can filling and seaming machine can help manufacturers meet the growing demand for convenience and portability in the beverage industry. Aluminum cans are a popular packaging option for juice due to their lightweight and recyclable nature, making them ideal for on-the-go consumption. By using a fully automatic machine to fill and seal these cans, manufacturers can quickly and efficiently meet the needs of consumers who are looking for convenient and portable beverage options.

Another key benefit of a fully automatic juice aluminum can filling and seaming machine is its ability to improve overall safety and hygiene in the production process. Manual filling and sealing processes can expose workers to potential hazards, such as spills and contamination. By automating these processes, manufacturers can reduce the risk of accidents and ensure that the product is packaged in a clean and sanitary environment.

In conclusion, investing in a fully automatic juice aluminum can filling and seaming machine can provide numerous benefits to manufacturers in the beverage industry. From increased production output and improved product quality to meeting consumer demand for convenience and ensuring safety and hygiene in the production process, this advanced machine offers a wide range of advantages. By incorporating this technology into their operations, manufacturers can streamline their production process, enhance the quality of their product, and ultimately increase their competitiveness in the market.

How to Choose the Right Fully Automatic Juice Aluminum Can Filling and Seaming Machine for Your Production Line

Fully automatic juice aluminum can filling and seaming machines are essential equipment for any beverage production line. These machines are designed to efficiently fill aluminum cans with juice and seal them with a lid, ensuring a hygienic and airtight seal. Choosing the right fully automatic juice aluminum can filling and seaming machine for your production line is crucial to ensure smooth operations and high-quality output.

When selecting a fully automatic juice aluminum can filling and seaming machine, there are several factors to consider. One of the most important factors to consider is the production capacity of the machine. You need to determine the volume of juice cans you need to fill and seal per hour to meet your production requirements. Make sure to choose a machine that can handle your desired production capacity to avoid bottlenecks in your production line.

Another important factor to consider is the size and shape of the aluminum cans that the machine can handle. Different machines are designed to accommodate different sizes and shapes of cans, so make sure to choose a machine that is compatible with the cans you will be using. Additionally, consider the flexibility of the machine in terms of adjusting to different can sizes and shapes, as this can be beneficial if you plan to introduce new products in the future.

The filling accuracy of the machine is also a crucial factor to consider. You want to ensure that the machine can accurately fill each can with the correct amount of juice to maintain consistency in your product quality. Look for a machine that offers precise filling controls and adjustments to meet your specific filling requirements.

In addition to filling accuracy, consider the sealing quality of the machine. A fully automatic juice aluminum can filling and seaming machine should be able to seal each can with a tight and secure lid to prevent leakage and contamination. Look for a machine that offers reliable seaming technology to ensure a consistent and reliable seal on each can.

Ease of operation and maintenance are also important considerations when choosing a fully automatic juice aluminum can filling and seaming machine. Look for a machine that is user-friendly and easy to operate, with intuitive controls and minimal training requirements for your operators. Additionally, consider the maintenance requirements of the machine and choose a model that is easy to clean and maintain to minimize downtime and ensure smooth operations.

Finally, consider the overall reliability and reputation of the manufacturer when choosing a fully automatic juice aluminum can filling and seaming machine. Look for a reputable manufacturer with a track record of producing high-quality and reliable machines. Read reviews and testimonials from other customers to gauge the performance and reliability of the machine before making a decision.

In conclusion, choosing the right fully automatic juice aluminum can filling and seaming machine for your production line is essential to ensure efficient operations and high-quality output. Consider factors such as production capacity, can size compatibility, filling accuracy, sealing quality, ease of operation and maintenance, and manufacturer reputation when making your decision. By carefully evaluating these factors, you can select a machine that meets your specific requirements and helps you achieve success in your beverage production operations.