Maximizing Efficiency with the Fully Automatic Coffee Beans 4 Head Linear Weighing Filling Production Line

Maximizing efficiency in the coffee production industry is a critical aspect that can significantly impact the overall productivity and profitability of a business. One of the most innovative solutions that have revolutionized this sector is the Fully Automatic Coffee Beans 4 Head Linear Weighing Filling Production Line. This state-of-the-art technology has been designed to streamline the coffee production process, ensuring precision, speed, and consistency.

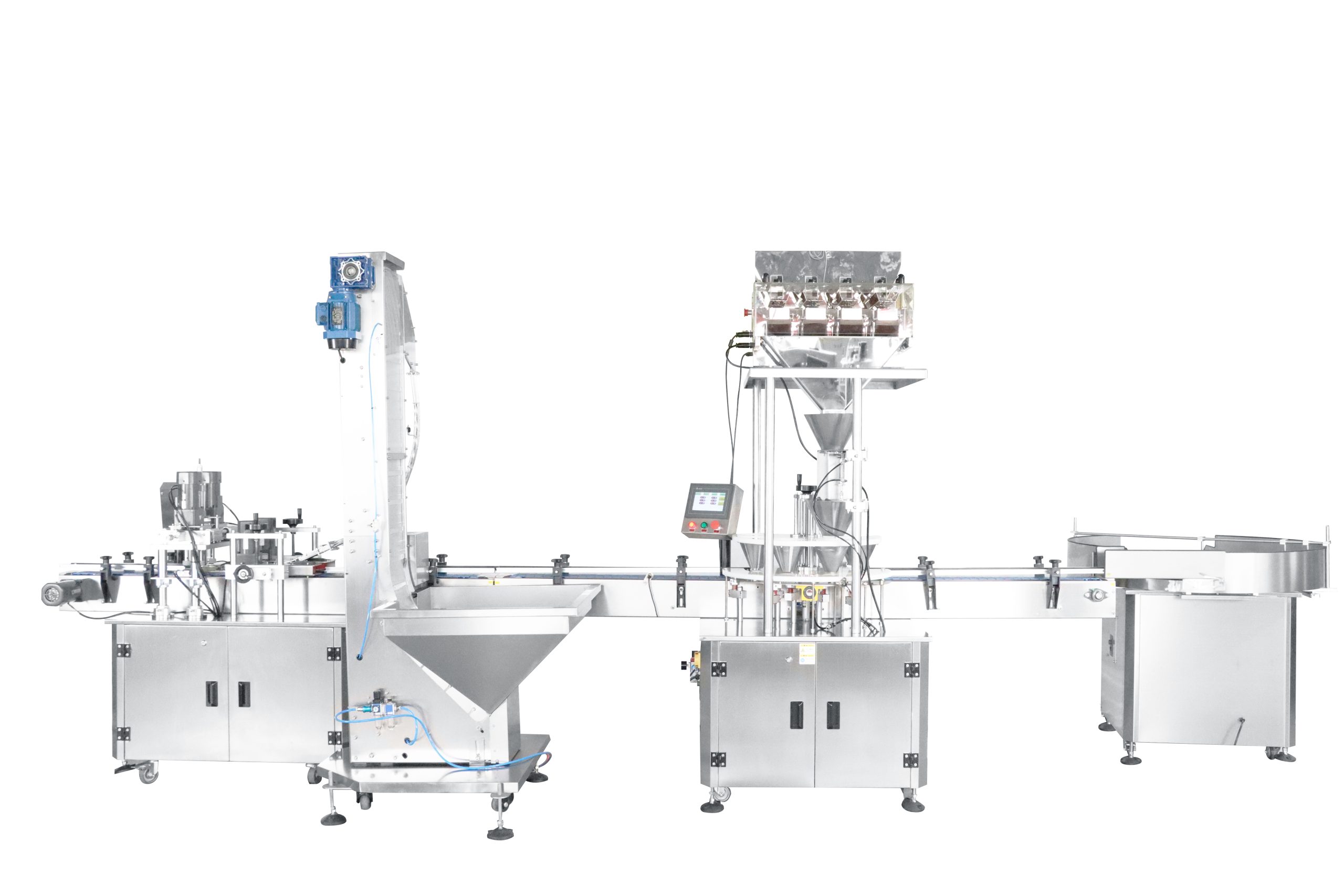

The Fully Automatic Coffee Beans 4 Head Linear Weighing Filling Production Line is a comprehensive system that integrates several functions into one seamless operation. It is primarily designed to handle the weighing and filling of coffee beans, but its capabilities extend far beyond these tasks. The system is fully automated, which eliminates the need for manual intervention, thereby reducing the risk of human error and increasing the overall efficiency of the production process.

The system operates by first dispensing the coffee beans into a weighing chamber. Here, the beans are accurately weighed to ensure that each package contains the exact amount of product. This precision is crucial in maintaining consistency in product quality and meeting customer expectations. Once the beans are weighed, they are then automatically transferred to the filling station. The filling process is also automated, ensuring that each package is filled quickly and accurately.

One of the most significant advantages of the Fully Automatic Coffee Beans 4 Head Linear Weighing Filling Production Line is its speed. The system can handle a high volume of coffee beans, making it an ideal solution for large-scale coffee producers. The four-head design allows the system to weigh and fill multiple packages simultaneously, significantly reducing the time it takes to complete the production process.

Moreover, the Fully Automatic Coffee Beans 4 Head Linear Weighing Filling Production Line is designed with user-friendly interfaces that make it easy to operate. The system’s settings can be easily adjusted to accommodate different types of coffee beans and package sizes. This flexibility allows coffee producers to diversify their product offerings without having to invest in additional equipment.

The system’s automation also contributes to its cost-effectiveness. By eliminating the need for manual labor, the Fully Automatic Coffee Beans 4 Head Linear Weighing Filling Production Line reduces labor costs. Additionally, the system’s precision in weighing and filling reduces waste, which can result in significant cost savings in the long run.

In conclusion, the Fully Automatic Coffee Beans 4 Head Linear Weighing Filling Production Line is a game-changer in the coffee production industry. Its integration of weighing and filling functions, high-speed operation, user-friendly design, and cost-effectiveness make it an invaluable asset for any coffee producer looking to maximize efficiency. By investing in this innovative technology, coffee producers can significantly enhance their productivity, improve product quality, and increase their profitability.