Table of Contents

Maximizing Efficiency with Fully Automatic Bowl Cans Packaging Production Line

Maximizing efficiency in the production process is a key objective for any manufacturing business. One area where efficiency can be significantly improved is in the packaging process. This is particularly true in the food industry, where the packaging of bowl cans is a critical step in the production line. The introduction of fully automatic bowl cans packaging production lines has revolutionized this process, offering a host of benefits that can greatly enhance operational efficiency.

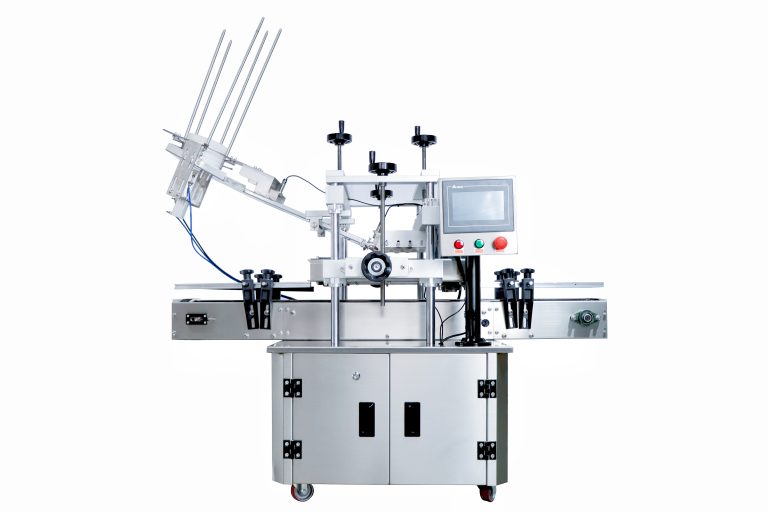

A fully automatic bowl cans packaging production line is a sophisticated piece of machinery that automates the entire packaging process. This includes everything from filling the cans with the product, sealing them, labeling, and finally, packing them into boxes for shipment. The automation of these steps eliminates the need for manual labor, thereby reducing the risk of human error and increasing the speed of production.

One of the primary advantages of a fully automatic bowl cans packaging production line is its speed. These machines can package hundreds, if not thousands, of cans per hour. This is significantly faster than what could be achieved manually, allowing businesses to meet high demand levels more effectively. Moreover, the speed of these machines can be adjusted to match the pace of other processes in the production line, ensuring a smooth and seamless operation.

Another significant benefit of these machines is their precision. The fully automatic bowl cans packaging production line is designed to fill each can with an exact amount of product. This precision ensures consistency across all products, which is crucial for maintaining quality standards and customer satisfaction. Furthermore, the machine’s precision extends to its sealing and labeling functions, ensuring that each can is perfectly sealed and accurately labeled.

The fully automatic nature of these machines also reduces labor costs. With less need for manual labor, businesses can redirect their workforce to other areas where they can add more value. Additionally, the reduction in labor also minimizes the risk of workplace injuries, as the machine handles the heavy lifting and repetitive tasks.

The use of a fully automatic bowl cans packaging production line also contributes to waste reduction. The precision of these machines ensures that there is minimal product wastage during the filling process. Moreover, the machines are designed to handle each can carefully, reducing the likelihood of damage and subsequent waste.

In terms of maintenance, these machines are designed for durability and long-term use. Regular maintenance checks and timely repairs can ensure that the machine continues to operate at optimal efficiency. Moreover, many of these machines come with built-in diagnostic tools that can identify and troubleshoot issues, minimizing downtime.

In conclusion, a fully automatic bowl cans packaging production line offers numerous benefits that can significantly enhance operational efficiency. Its speed, precision, and automation can lead to increased production, reduced labor costs, and minimized waste. While the initial investment in these machines may be substantial, the long-term benefits they offer make them a worthwhile investment for businesses looking to maximize their efficiency in the packaging process.

Innovations in Food Industry: The Role of Fully Automatic Bowl Cans Packaging Production Line

In the ever-evolving food industry, technological advancements have played a pivotal role in enhancing efficiency, productivity, and quality. One such innovation that has revolutionized the sector is the fully automatic bowl cans packaging production line. This state-of-the-art technology has not only streamlined the packaging process but also significantly reduced manual labor, thereby increasing the overall output.

The fully automatic bowl cans packaging production line is a comprehensive system that integrates various functions such as filling, sealing, and labeling into a single, seamless operation. This technology is designed to handle a wide range of products, from soups and sauces to ready-to-eat meals, making it a versatile solution for food manufacturers.

The process begins with the automatic feeding of empty cans onto the production line. These cans are then filled with the product using precision technology that ensures consistent quantity and quality. Following this, the cans are sealed to preserve the freshness and flavor of the food. The sealing process is crucial as it prevents contamination and extends the shelf life of the product. Once sealed, the cans are labeled with relevant information such as ingredients, nutritional facts, and expiry dates. The entire process is carried out at a rapid pace, enabling manufacturers to package thousands of cans in a single hour.

One of the key benefits of the fully automatic bowl cans packaging production line is its high efficiency. By automating the packaging process, manufacturers can significantly increase their production capacity. This not only helps meet the growing demand for packaged food but also reduces the time to market, giving manufacturers a competitive edge.

Moreover, this technology eliminates the need for manual labor in the packaging process, thereby reducing the risk of human error. This ensures that each can is filled, sealed, and labeled accurately, resulting in a high-quality product. Additionally, automation reduces the risk of workplace injuries, creating a safer environment for employees.

Another significant advantage of the fully automatic bowl cans packaging production line is its cost-effectiveness. While the initial investment may be substantial, the long-term savings in terms of labor costs and increased productivity make it a worthwhile investment. Furthermore, the use of advanced technology ensures minimal wastage, further contributing to cost savings.

The fully automatic bowl cans packaging production line also offers flexibility. It can be easily adjusted to handle different sizes and types of cans, making it suitable for a wide range of products. This allows manufacturers to diversify their product range without the need for additional equipment.

In conclusion, the fully automatic bowl cans packaging production line is a game-changer in the food industry. Its high efficiency, accuracy, cost-effectiveness, and flexibility make it an invaluable tool for food manufacturers. As consumer demand for packaged food continues to grow, this technology is set to play an increasingly important role in meeting this demand. By embracing this innovation, food manufacturers can not only enhance their productivity but also improve the quality of their products, thereby gaining a competitive advantage in the market.