Table of Contents

Maximizing Efficiency with Fully Auto Chili Sauce Can Packaging Production Line

In the fast-paced world of food production, efficiency is key. One area where this is particularly evident is in the packaging of chili sauce. The fully auto chili sauce can packaging production line is a game-changer in this regard, offering a host of benefits that can significantly enhance productivity and profitability.

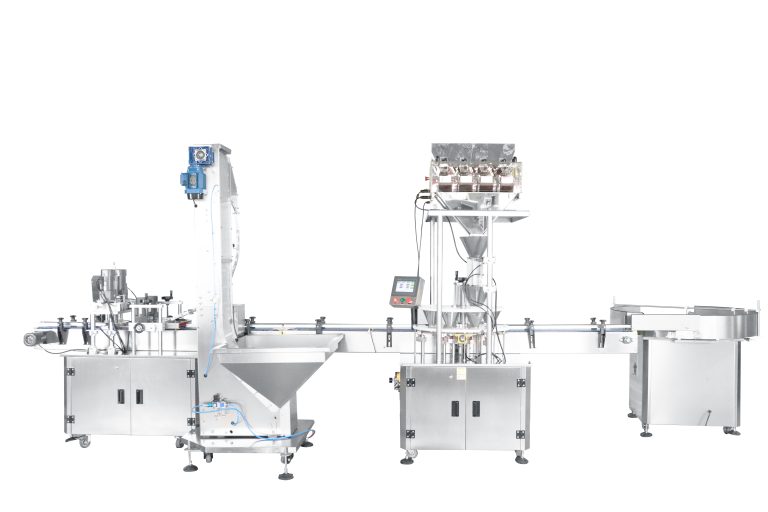

The fully auto chili sauce can packaging production line is a marvel of modern engineering. It integrates various processes such as filling, sealing, and labeling into a single, streamlined operation. This not only saves time but also reduces the potential for errors that can occur when these tasks are performed separately. The result is a more efficient production process that can handle large volumes of chili sauce cans quickly and accurately.

One of the most significant advantages of the fully auto chili sauce can packaging production line is its speed. With the ability to process hundreds, if not thousands, of cans per hour, it far outpaces manual or semi-automatic methods. This high-speed operation is made possible by advanced automation technology, which ensures that each can is filled, sealed, and labeled with precision and consistency.

Moreover, the fully auto chili sauce can packaging production line is designed to minimize waste. The filling mechanism is engineered to dispense the exact amount of chili sauce into each can, eliminating overfilling or underfilling. This not only conserves resources but also ensures that each can contains the correct amount of product, which is crucial for maintaining quality standards and customer satisfaction.

In addition to speed and accuracy, the fully auto chili sauce can packaging production line also offers exceptional reliability. Built with high-quality materials and components, it is designed to withstand the rigors of continuous operation. Regular maintenance is straightforward and downtime is minimal, ensuring that production can continue uninterrupted.

Furthermore, the fully auto chili sauce can packaging production line is remarkably flexible. It can accommodate cans of different sizes and shapes, making it suitable for a wide range of chili sauce products. This versatility means that manufacturers can easily switch between different products without having to invest in separate packaging equipment.

The fully auto chili sauce can packaging production line also contributes to improved workplace safety. By automating the packaging process, it reduces the need for manual labor, thereby minimizing the risk of injuries that can result from handling heavy equipment or exposure to hot chili sauce.

Finally, the fully auto chili sauce can packaging production line is a cost-effective solution. While the initial investment may be higher than for manual or semi-automatic methods, the long-term savings in terms of time, labor, and resources can more than offset the upfront cost. Moreover, the increased productivity and efficiency can lead to higher profits, making the fully auto chili sauce can packaging production line a sound investment for any chili sauce manufacturer.

In conclusion, the fully auto chili sauce can packaging production line is a powerful tool for maximizing efficiency in chili sauce production. With its speed, accuracy, reliability, flexibility, safety features, and cost-effectiveness, it offers a comprehensive solution that can meet the demands of today’s competitive food industry. By embracing this technology, chili sauce manufacturers can not only enhance their productivity but also gain a competitive edge in the market.

Innovations in Food Industry: The Impact of Fully Auto Chili Sauce Can Packaging Production Line

In the ever-evolving food industry, technological advancements have been instrumental in enhancing efficiency, productivity, and quality. One such innovation that has significantly impacted the sector is the fully auto chili sauce can packaging production line. This state-of-the-art technology has revolutionized the packaging process, offering a myriad of benefits to manufacturers and consumers alike.

The fully auto chili sauce can packaging production line is a marvel of modern engineering. It integrates various processes such as filling, sealing, and labeling into a single, streamlined operation. This automated system is designed to handle the packaging of chili sauce in cans, a task that was traditionally labor-intensive and time-consuming. The automation of these processes has not only increased the speed of production but also significantly reduced the risk of human error, ensuring a consistently high quality of the final product.

The introduction of this technology has had a profound impact on the food industry. For manufacturers, the fully auto chili sauce can packaging production line has resulted in substantial cost savings. By eliminating the need for manual labor in the packaging process, companies can redirect their resources towards other critical areas of their business. Furthermore, the increased speed of production has enabled manufacturers to meet the growing demand for chili sauce, thereby boosting their profitability.

In addition to the economic benefits, the fully auto chili sauce can packaging production line also offers significant environmental advantages. The system is designed to minimize waste, making it a more sustainable option compared to traditional packaging methods. By reducing the amount of packaging material used and optimizing the use of resources, this technology contributes to the industry’s efforts to reduce its environmental footprint.

From a consumer perspective, the fully auto chili sauce can packaging production line ensures the delivery of high-quality products. The automation of the packaging process eliminates the risk of contamination, which is a common concern with manual packaging. Moreover, the precise filling and sealing mechanisms of the system ensure that each can of chili sauce is perfectly packaged, enhancing the overall consumer experience.

The fully auto chili sauce can packaging production line also has the potential to drive innovation in the food industry. As this technology continues to evolve, it could pave the way for the development of new packaging solutions that further enhance efficiency and sustainability. For instance, the system could be adapted to package other types of sauces or condiments, expanding its applicability and impact.

In conclusion, the fully auto chili sauce can packaging production line is a game-changing innovation in the food industry. By automating the packaging process, this technology has enhanced efficiency, reduced costs, and improved product quality. Moreover, its potential to drive further innovation and sustainability in the sector underscores its significance. As the food industry continues to evolve, technologies like the fully auto chili sauce can packaging production line will undoubtedly play a pivotal role in shaping its future.