Table of Contents

Benefits of Using Automated Fruit Juice Filling and Capping Machines

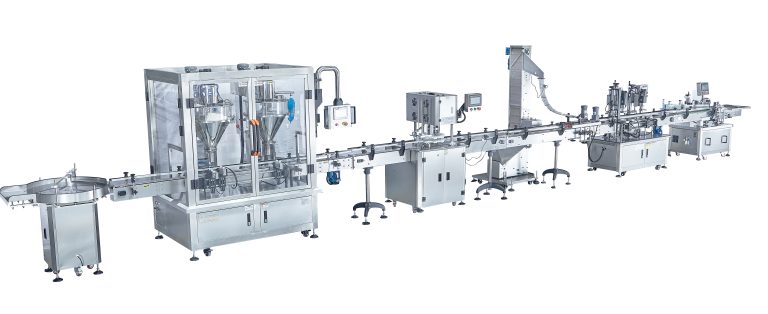

In the world of food and beverage production, efficiency and consistency are key factors in ensuring a successful operation. When it comes to filling and capping fruit juice bottles, having an automated system in place can greatly improve the overall process. Automated fruit juice filling and capping machines offer a wide range of benefits that can help streamline production and increase output.

One of the main advantages of using automated fruit juice filling and capping machines is the speed at which they can operate. These machines are designed to fill and cap bottles at a much faster rate than manual labor, allowing for higher production volumes in a shorter amount of time. This increased speed can help companies meet demand and fulfill orders more efficiently, ultimately leading to higher profits.

In addition to speed, automated fruit juice filling and capping machines also offer a higher level of accuracy and consistency. These machines are programmed to fill each bottle with the exact amount of juice, ensuring that every product meets the same quality standards. This level of precision is difficult to achieve with manual labor, where human error can lead to inconsistencies in product quality. By using automated machines, companies can guarantee that every bottle of fruit juice is filled and capped correctly, leading to a more reliable and reputable product.

Another benefit of using automated fruit juice filling and capping machines is the reduction of labor costs. By automating the filling and capping process, companies can significantly decrease the amount of manual labor required to produce their products. This not only saves money on labor expenses but also frees up employees to focus on other tasks within the production line. With automated machines handling the filling and capping process, employees can be reassigned to more skilled or specialized roles, further improving overall efficiency and productivity.

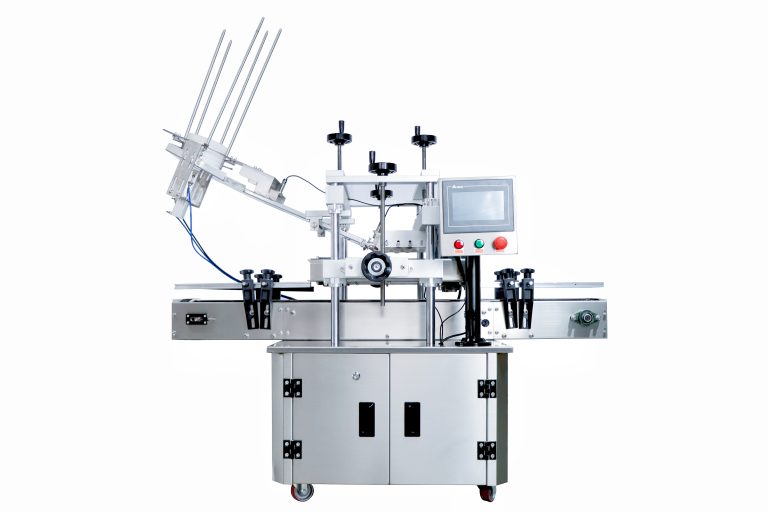

Furthermore, automated fruit juice filling and capping machines are designed to be easy to operate and maintain. These machines are equipped with user-friendly interfaces that allow operators to quickly set up and adjust the machine for different bottle sizes and production runs. Additionally, automated machines require less maintenance than manual labor, as they are built to withstand the rigors of continuous use. This means that companies can rely on their automated machines to consistently perform at a high level without the need for frequent repairs or downtime.

Overall, the benefits of using automated fruit juice filling and capping machines are clear. From increased speed and accuracy to reduced labor costs and ease of operation, these machines offer a wide range of advantages that can help companies improve their production processes and increase profitability. By investing in automated machines, companies can streamline their operations, produce higher quality products, and ultimately achieve greater success in the competitive food and beverage industry.

How to Ensure Proper Labeling and Packaging of Fruit Juice Products

Fruit juice is a popular beverage enjoyed by people of all ages around the world. With its refreshing taste and numerous health benefits, it’s no wonder that fruit juice products are in high demand. However, in order to ensure that these products reach consumers in the best possible condition, proper labeling and packaging are essential.

When it comes to fruit juice filling and capping labeling packaging lines, there are several key factors to consider. First and foremost, it is important to ensure that the labeling and packaging process is efficient and accurate. This means using high-quality equipment that is capable of handling the specific requirements of fruit juice products.

One of the most important aspects of the labeling and packaging process is ensuring that the correct information is displayed on the product packaging. This includes details such as the product name, ingredients, nutritional information, and expiration date. Inaccurate or incomplete labeling can lead to confusion among consumers and may even result in legal issues for the manufacturer.

To ensure that the labeling and packaging process runs smoothly, it is important to invest in equipment that is specifically designed for fruit juice products. This includes filling machines that are capable of accurately measuring and dispensing the correct amount of juice into each bottle, as well as capping machines that can securely seal the bottles to prevent leakage.

In addition to using the right equipment, it is also important to have a well-trained and experienced team overseeing the labeling and packaging process. This includes individuals who are familiar with the specific requirements of fruit juice products and who can ensure that all labeling and packaging is done correctly.

Another important consideration when it comes to fruit juice filling and capping labeling packaging lines is the use of high-quality packaging materials. This includes bottles that are durable and leak-proof, as well as labels that are resistant to moisture and fading. Using subpar packaging materials can result in product spoilage and can damage the reputation of the brand.

In order to ensure that fruit juice products are properly labeled and packaged, it is also important to adhere to all relevant regulations and guidelines. This includes following food safety standards and ensuring that all labeling is compliant with local and international regulations. Failure to comply with these regulations can result in fines and other penalties for the manufacturer.

Overall, proper labeling and packaging are essential for ensuring that fruit juice products reach consumers in the best possible condition. By investing in high-quality equipment, using the right packaging materials, and adhering to regulations, manufacturers can ensure that their products are safe, attractive, and appealing to consumers. With the right approach, fruit juice filling and capping labeling packaging lines can be efficient, accurate, and successful in delivering high-quality products to the market.

Tips for Increasing Efficiency in Fruit Juice Filling and Capping Lines

Fruit juice filling and capping lines are essential components of any fruit juice production facility. These lines are responsible for filling bottles with juice, capping them securely, labeling them accurately, and packaging them for distribution. Efficiency in these processes is crucial for maximizing productivity and minimizing waste. Here are some tips for increasing efficiency in fruit juice filling and capping lines.

One of the key factors in improving efficiency in fruit juice filling and capping lines is proper maintenance of equipment. Regular maintenance and cleaning of filling and capping machines can help prevent breakdowns and ensure smooth operation. It is important to follow the manufacturer’s guidelines for maintenance and to schedule routine inspections to identify and address any issues before they become major problems.

Another important aspect of increasing efficiency in fruit juice filling and capping lines is optimizing the production process. This includes streamlining the workflow, minimizing downtime between batches, and maximizing the use of available resources. By carefully planning and organizing the production process, you can reduce bottlenecks and improve overall efficiency.

Investing in automation technology can also help increase efficiency in fruit juice filling and capping lines. Automated filling and capping machines can significantly speed up the production process and reduce the risk of human error. By automating repetitive tasks, you can free up your workforce to focus on more complex and value-added activities, further improving efficiency.

In addition to automation, implementing quality control measures can help ensure that only high-quality products are being produced. By regularly testing and monitoring the quality of the fruit juice throughout the production process, you can identify and address any issues before they impact the final product. This can help reduce waste and improve overall efficiency.

Proper training of staff is another important factor in increasing efficiency in fruit juice filling and capping lines. By providing comprehensive training on equipment operation, safety procedures, and quality control measures, you can ensure that your workforce is equipped to perform their jobs effectively and efficiently. Regular training sessions and refresher courses can help keep staff up to date on best practices and new technologies.

Finally, optimizing packaging and labeling processes can help increase efficiency in fruit juice filling and capping lines. By using standardized packaging materials and labeling templates, you can streamline the packaging process and reduce the risk of errors. Investing in high-quality labeling equipment can also help ensure that labels are applied accurately and securely, further improving efficiency.

In conclusion, increasing efficiency in fruit juice filling and capping lines requires a combination of proper maintenance, optimized production processes, automation technology, quality control measures, staff training, and packaging and labeling optimization. By implementing these tips, you can improve productivity, reduce waste, and ultimately increase profitability in your fruit juice production facility.