Table of Contents

Benefits of Using Fruit Jam Filling Capping Machine Production Line

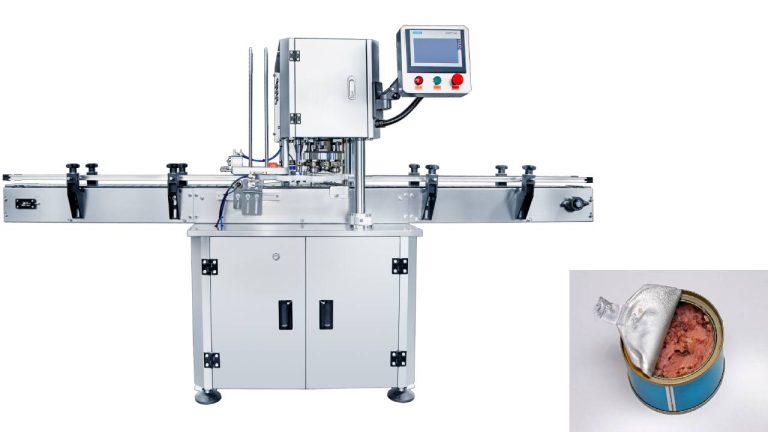

Fruit jam filling capping machine production lines are an essential component of any food processing facility that produces fruit jams and preserves. These machines offer a range of benefits that can help streamline the production process and improve overall efficiency.

One of the key benefits of using a fruit jam filling capping machine production line is the increased speed and consistency of production. These machines are designed to fill and cap jars of fruit jam quickly and accurately, reducing the need for manual labor and ensuring that each jar is filled to the correct level. This can help to increase output and reduce production times, allowing manufacturers to meet demand more effectively.

In addition to increased speed, fruit jam filling capping machines also offer improved accuracy and consistency. These machines are equipped with sensors and controls that ensure each jar is filled with the correct amount of jam and capped securely. This helps to reduce waste and ensure that every jar meets the same high-quality standards, improving overall product consistency and customer satisfaction.

Another benefit of using a fruit jam filling capping machine production line is the reduction of labor costs. By automating the filling and capping process, manufacturers can reduce the need for manual labor and reallocate resources to other areas of the production process. This can help to lower overall production costs and improve profitability in the long run.

Furthermore, fruit jam filling capping machines are designed to be easy to operate and maintain, reducing the need for specialized training and technical expertise. This can help to streamline the production process and minimize downtime, ensuring that manufacturers can continue to meet demand without interruption.

Additionally, fruit jam filling capping machines are versatile and can be easily customized to meet the specific needs of different products and production lines. Manufacturers can adjust settings such as filling speed, jar size, and capping pressure to ensure that each jar is filled and capped correctly. This flexibility can help to improve overall efficiency and productivity, allowing manufacturers to adapt to changing market demands quickly.

Overall, the benefits of using a fruit jam filling capping machine production line are clear. These machines offer increased speed, accuracy, and consistency, as well as reduced labor costs and improved versatility. By investing in a fruit jam filling capping machine production line, manufacturers can streamline their production process, improve product quality, and ultimately increase profitability.

How to Choose the Right Fruit Jam Filling Capping Machine for Your Production Line

When it comes to choosing the right fruit jam filling capping machine for your production line, there are several factors to consider. From the size and speed of the machine to the type of fruit jam you will be filling and capping, it’s important to carefully evaluate your needs before making a decision. In this article, we will discuss some key considerations to keep in mind when selecting a fruit jam filling capping machine for your production line.

One of the first things to consider when choosing a fruit jam filling capping machine is the size and speed of the machine. The size of the machine will depend on the volume of fruit jam you plan to produce, so it’s important to choose a machine that can handle your production needs. Additionally, the speed of the machine will impact the efficiency of your production line, so be sure to select a machine that can keep up with your desired output.

Another important factor to consider is the type of fruit jam you will be filling and capping. Different types of fruit jam may require different filling and capping techniques, so it’s important to choose a machine that is compatible with the specific type of fruit jam you will be working with. Additionally, some machines may be better suited for certain types of fruit jam, so be sure to do your research and choose a machine that is designed for the specific needs of your product.

In addition to size, speed, and compatibility, it’s also important to consider the quality and reliability of the machine. Look for a machine that is made from high-quality materials and is built to last. Additionally, choose a machine from a reputable manufacturer with a track record of producing reliable and efficient equipment. Investing in a high-quality machine will help ensure that your production line runs smoothly and efficiently, minimizing downtime and maximizing productivity.

When selecting a fruit jam filling capping machine, it’s also important to consider the level of automation you require. Some machines offer fully automated filling and capping processes, while others may require more manual intervention. Consider your production needs and the level of automation that will best suit your operation. Additionally, consider any additional features or capabilities that may be important for your production line, such as the ability to fill multiple containers at once or the option to customize filling and capping settings.

In conclusion, choosing the right fruit jam filling capping machine for your production line is a critical decision that can impact the efficiency and success of your operation. Consider factors such as size, speed, compatibility, quality, reliability, and automation when making your decision. By carefully evaluating your needs and selecting a machine that meets your specific requirements, you can ensure that your production line runs smoothly and efficiently, producing high-quality fruit jam products for your customers.

Maintenance Tips for Fruit Jam Filling Capping Machine Production Line

Fruit jam filling capping machines are essential equipment in the food processing industry, particularly for companies that produce jams and preserves on a large scale. These machines are designed to efficiently fill jars with fruit jam, seal them with caps, and ensure airtight packaging to preserve the freshness and quality of the product. To ensure the smooth operation of a fruit jam filling capping machine production line, regular maintenance is crucial.

One of the most important maintenance tasks for a fruit jam filling capping machine production line is cleaning. Regular cleaning of the machine components, such as the filling nozzles, capping heads, and conveyor belts, is essential to prevent the buildup of jam residue and other contaminants that can affect the quality of the product and the efficiency of the machine. It is recommended to clean the machine after each production run and conduct a more thorough cleaning at the end of each day.

In addition to cleaning, it is important to inspect the machine regularly for any signs of wear and tear. Check for loose or damaged parts, such as belts, gears, and seals, and replace them as needed to prevent breakdowns and ensure the smooth operation of the machine. It is also important to lubricate the moving parts of the machine regularly to reduce friction and prevent premature wear.

Another important maintenance task for a fruit jam filling capping machine production line is calibration. Calibration ensures that the machine is filling jars with the correct amount of jam and sealing them properly. It is important to calibrate the machine regularly to maintain the accuracy of the filling and capping processes and ensure consistent product quality. If the machine is not calibrated correctly, it can result in underfilled or overfilled jars, which can affect the shelf life and appearance of the product.

Regular inspection of the electrical components of the machine is also important to prevent electrical issues that can cause downtime and affect production. Check the wiring, switches, and control panels for any signs of damage or wear, and replace any faulty components to prevent electrical malfunctions. It is also important to ensure that the machine is properly grounded to prevent electrical hazards.

In conclusion, regular maintenance is essential for ensuring the smooth operation of a fruit jam filling capping machine production line. By following these maintenance tips, companies can prevent breakdowns, ensure consistent product quality, and prolong the lifespan of their equipment. Investing time and resources in maintenance can help companies avoid costly repairs and downtime, ultimately leading to increased efficiency and profitability in the long run.