Table of Contents

Benefits of Using Automated Fish Feed Can Packaging Line

Fish feed can packaging lines are an essential component of the aquaculture industry, providing a convenient and efficient way to package and distribute fish feed to farms and fisheries. These automated packaging lines offer a range of benefits that can help improve productivity, reduce costs, and ensure the quality and freshness of the fish feed.

One of the key benefits of using an automated fish feed can packaging line is the increased efficiency it provides. These packaging lines are designed to handle large volumes of fish feed quickly and accurately, reducing the need for manual labor and streamlining the packaging process. This can help to increase productivity and reduce the time and resources required to package and distribute fish feed.

In addition to improving efficiency, automated fish feed can packaging lines can also help to reduce costs. By automating the packaging process, companies can save money on labor costs and minimize waste. These packaging lines are designed to be highly efficient and accurate, ensuring that each can of fish feed is filled to the correct weight and sealed properly. This can help to reduce the amount of product that is wasted due to overfilling or underfilling, saving companies money in the long run.

Another benefit of using an automated fish feed can packaging line is the improved quality and freshness of the fish feed. These packaging lines are designed to protect the fish feed from contamination and spoilage, ensuring that it remains fresh and safe for consumption. The automated packaging process helps to seal the fish feed in airtight cans, preventing exposure to air, moisture, and other contaminants that can degrade the quality of the product. This can help to extend the shelf life of the fish feed and ensure that it reaches customers in optimal condition.

Furthermore, automated fish feed can packaging lines can help to improve the overall safety and hygiene of the packaging process. These packaging lines are designed to meet strict food safety standards and regulations, ensuring that the fish feed is packaged in a clean and sanitary environment. The automated process helps to minimize the risk of contamination and cross-contamination, reducing the likelihood of foodborne illnesses and ensuring the safety of the product for consumers.

In conclusion, automated fish feed can packaging lines offer a range of benefits that can help to improve productivity, reduce costs, and ensure the quality and freshness of the fish feed. These packaging lines are designed to be efficient, accurate, and hygienic, providing companies with a reliable and cost-effective way to package and distribute fish feed. By investing in an automated fish feed can packaging line, companies can streamline their packaging process, reduce waste, and ensure that their product reaches customers in optimal condition.

How to Choose the Right Fish Feed Can Packaging Line for Your Business

When it comes to packaging fish feed cans, choosing the right packaging line for your business is crucial. The packaging line you select will impact the efficiency, productivity, and overall success of your operation. With so many options available on the market, it can be overwhelming to decide which fish feed can packaging line is the best fit for your business. In this article, we will discuss some key factors to consider when choosing a fish feed can packaging line to help you make an informed decision.

One of the first things to consider when selecting a fish feed can packaging line is the production capacity of your business. You need to determine how many cans of fish feed you need to package per hour or per day to meet the demands of your customers. This will help you narrow down your options and choose a packaging line that can handle the volume of production required for your business.

Another important factor to consider is the size and shape of the fish feed cans you will be packaging. Different packaging lines are designed to accommodate different sizes and shapes of cans, so it is essential to choose a packaging line that is compatible with the cans you will be using. This will ensure that your cans are properly sealed and packaged, preventing any damage or contamination during the packaging process.

In addition to production capacity and can size, you should also consider the level of automation you require in a fish feed can packaging line. Some packaging lines are fully automated, while others require more manual labor. The level of automation you choose will depend on your budget, production volume, and the level of precision required in the packaging process. Fully automated packaging lines can increase efficiency and reduce labor costs, but they may also require a larger upfront investment.

Furthermore, it is essential to consider the quality and reliability of the packaging line manufacturer. You want to choose a reputable manufacturer with a track record of producing high-quality packaging lines that are durable and reliable. Researching customer reviews and testimonials can help you determine the reputation of a manufacturer and ensure that you are investing in a packaging line that will meet your business needs.

Cost is another critical factor to consider when choosing a fish feed can packaging line. You need to determine your budget and find a packaging line that fits within your financial constraints. While it may be tempting to choose the cheapest option available, it is essential to consider the long-term costs of maintenance, repairs, and downtime. Investing in a high-quality packaging line may cost more upfront but can save you money in the long run by reducing maintenance and repair costs.

In conclusion, choosing the right fish feed can packaging line for your business is a decision that should not be taken lightly. Consider factors such as production capacity, can size, level of automation, manufacturer reputation, and cost when making your decision. By carefully evaluating these factors and conducting thorough research, you can select a packaging line that will help your business operate efficiently and effectively.

Top Trends in Fish Feed Can Packaging Line Technology

Fish feed can packaging lines have seen significant advancements in technology in recent years, with manufacturers constantly striving to improve efficiency, productivity, and overall quality. These advancements have been driven by the increasing demand for high-quality fish feed products, as well as the need for more sustainable packaging solutions. In this article, we will explore some of the top trends in fish feed can packaging line technology.

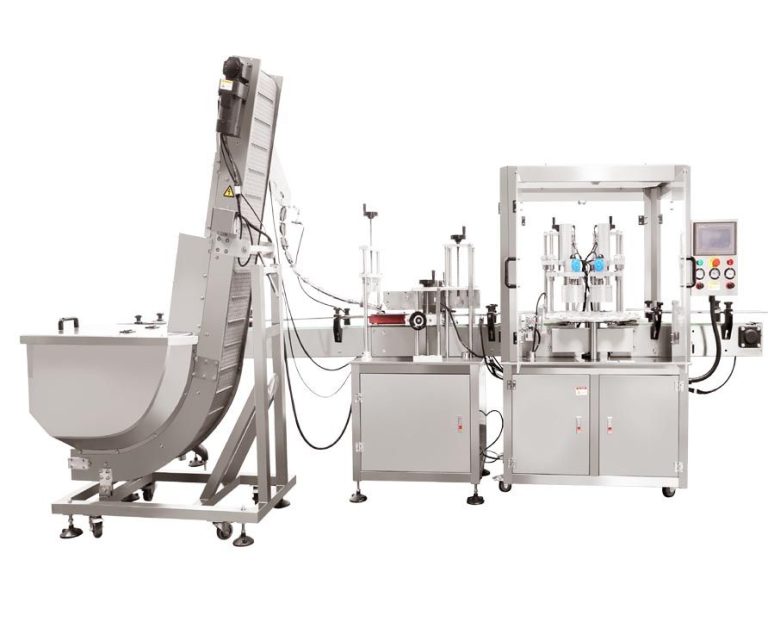

One of the key trends in fish feed can packaging line technology is the use of automation and robotics. Automation has revolutionized the packaging industry, allowing manufacturers to increase production speeds, reduce labor costs, and improve overall efficiency. Robotics, in particular, have played a crucial role in streamlining the packaging process, with robots being used to handle tasks such as filling cans, sealing lids, and labeling products. This not only speeds up the packaging process but also ensures greater accuracy and consistency in the final product.

Another important trend in fish feed can packaging line technology is the use of advanced packaging materials. Manufacturers are increasingly turning to sustainable and eco-friendly packaging solutions, such as biodegradable cans and recyclable materials. These materials not only help reduce the environmental impact of packaging but also appeal to environmentally conscious consumers. In addition, advanced packaging materials can also help extend the shelf life of fish feed products, ensuring that they remain fresh and high-quality for longer periods.

In line with the growing demand for sustainable packaging solutions, another trend in fish feed can packaging line technology is the use of smart packaging technologies. Smart packaging technologies incorporate features such as RFID tags, QR codes, and sensors to provide real-time information about the product, such as its origin, production date, and expiration date. This not only helps consumers make more informed purchasing decisions but also allows manufacturers to track and monitor their products throughout the supply chain, ensuring quality control and traceability.

Furthermore, the integration of data analytics and machine learning algorithms into fish feed can packaging lines is another emerging trend in the industry. By analyzing data collected from sensors and other sources, manufacturers can gain valuable insights into their packaging processes, identify areas for improvement, and optimize production efficiency. Machine learning algorithms can also help predict maintenance needs and prevent downtime, ensuring that packaging lines operate at peak performance.

Lastly, the trend towards customization and personalization in fish feed can packaging line technology is gaining momentum. Consumers are increasingly looking for products that cater to their specific needs and preferences, and packaging plays a crucial role in delivering a personalized experience. Manufacturers are responding to this demand by offering customizable packaging options, such as personalized labels, packaging designs, and portion sizes. This not only enhances the overall consumer experience but also helps build brand loyalty and differentiate products in a competitive market.

In conclusion, fish feed can packaging line technology is constantly evolving to meet the changing demands of the industry and consumers. From automation and robotics to sustainable packaging materials and smart packaging technologies, manufacturers are embracing innovation to improve efficiency, quality, and sustainability. By staying abreast of these top trends in fish feed can packaging line technology, manufacturers can position themselves for success in a rapidly evolving market.