Table of Contents

Benefits of Using Explosion-Proof Super Glue Can Filling and Sealing Machine Line

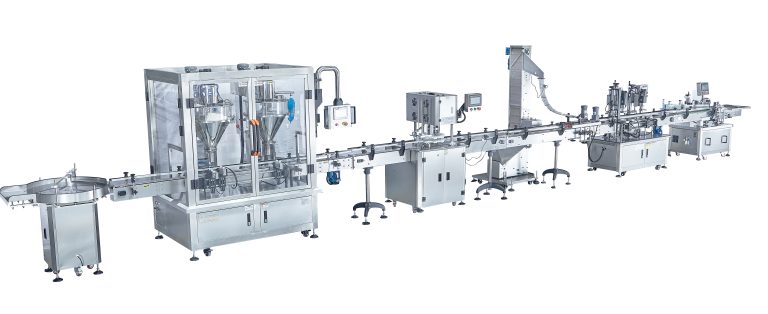

In industries where flammable materials are present, safety is of utmost importance. One such industry is the manufacturing of super glue, where the risk of explosion is a constant concern. To mitigate this risk, explosion-proof super glue can filling and sealing machine lines are used. These machines are designed to prevent sparks or heat from igniting flammable vapors, ensuring a safe working environment for operators.

One of the key benefits of using an explosion-proof super glue can filling and sealing machine line is the enhanced safety it provides. By eliminating the risk of sparks or heat sources igniting flammable vapors, these machines significantly reduce the likelihood of an explosion occurring. This not only protects the operators working with the machines but also safeguards the entire facility from potential damage.

Furthermore, the use of explosion-proof super glue can filling and sealing machine lines can help companies comply with safety regulations and standards. In industries where flammable materials are present, such as the manufacturing of super glue, strict safety guidelines must be followed to prevent accidents and ensure the well-being of employees. By investing in explosion-proof machinery, companies can demonstrate their commitment to safety and adherence to industry regulations.

In addition to safety benefits, explosion-proof super glue can filling and sealing machine lines also offer efficiency advantages. These machines are designed to fill and seal cans quickly and accurately, increasing productivity and reducing downtime. By automating the filling and sealing process, companies can streamline their operations and improve overall efficiency.

Moreover, explosion-proof super glue can filling and sealing machine lines are designed to be durable and long-lasting. These machines are built to withstand the rigors of industrial use, ensuring reliable performance over an extended period of time. By investing in high-quality machinery, companies can minimize maintenance costs and maximize the lifespan of their equipment.

Another benefit of using explosion-proof super glue can filling and sealing machine lines is the versatility they offer. These machines can be customized to meet the specific needs of different products and production processes. Whether filling small or large cans, or working with different types of super glue formulations, these machines can be tailored to accommodate a variety of requirements.

Overall, the use of explosion-proof super glue can filling and sealing machine lines offers a range of benefits for companies operating in industries where flammable materials are present. From enhanced safety and compliance with regulations to improved efficiency and durability, these machines provide a comprehensive solution for filling and sealing super glue cans. By investing in explosion-proof machinery, companies can protect their employees, streamline their operations, and demonstrate their commitment to safety and quality.

How to Choose the Right Explosion-Proof Super Glue Can Filling and Sealing Machine Line for Your Business

Explosion-proof super glue can filling and sealing machines are essential equipment for businesses that deal with flammable materials. These machines are designed to safely and efficiently fill and seal cans of super glue without the risk of sparking an explosion. Choosing the right explosion-proof super glue can filling and sealing machine line for your business is crucial to ensure the safety of your employees and the quality of your products.

When selecting an explosion-proof super glue can filling and sealing machine line, there are several factors to consider. The first and most important factor is the level of explosion protection that the machine line offers. Look for machines that are certified as explosion-proof and meet all relevant safety standards. These machines are designed to prevent sparks and other sources of ignition from coming into contact with flammable materials, reducing the risk of an explosion.

Another important factor to consider when choosing an explosion-proof super glue can filling and sealing machine line is the capacity of the machines. Consider the volume of super glue cans that your business produces and choose a machine line that can handle your production needs. It is important to select machines that are capable of filling and sealing cans quickly and efficiently to keep up with demand.

In addition to capacity, consider the flexibility of the machine line. Look for machines that can handle a variety of can sizes and shapes to accommodate different products. This will allow you to easily switch between different types of super glue cans without having to invest in multiple machine lines.

When selecting an explosion-proof super glue can filling and sealing machine line, it is also important to consider the ease of maintenance and operation. Look for machines that are easy to clean and maintain to ensure smooth operation and prevent downtime. Additionally, choose machines that are user-friendly and come with clear instructions for operation to minimize the risk of accidents.

Finally, consider the reputation of the manufacturer when choosing an explosion-proof super glue can filling and sealing machine line. Look for a manufacturer with a proven track record of producing high-quality, reliable machines. Reading reviews and testimonials from other businesses that have used the machine line can help you gauge the quality and performance of the machines.

In conclusion, choosing the right explosion-proof super glue can filling and sealing machine line for your business is essential to ensure the safety of your employees and the quality of your products. Consider factors such as explosion protection, capacity, flexibility, ease of maintenance and operation, and the reputation of the manufacturer when making your decision. By carefully evaluating these factors, you can select a machine line that meets your production needs and ensures the safe and efficient filling and sealing of super glue cans.

Safety Measures to Follow When Operating an Explosion-Proof Super Glue Can Filling and Sealing Machine Line

Explosion-proof super glue can filling and sealing machine lines are essential equipment in various industries that deal with hazardous materials. These machines are designed to safely fill and seal cans with super glue, ensuring that the product is securely packaged and ready for distribution. However, operating an explosion-proof super glue can filling and sealing machine line requires strict adherence to safety measures to prevent accidents and ensure the well-being of operators.

One of the most important safety measures to follow when operating an explosion-proof super glue can filling and sealing machine line is to wear appropriate personal protective equipment (PPE). This includes safety goggles, gloves, and a lab coat to protect against any potential splashes or spills of super glue. Additionally, operators should ensure that their clothing is not loose-fitting and that they tie back long hair to prevent it from getting caught in the machinery.

Before starting the machine line, operators should familiarize themselves with the operating manual and ensure that all safety features are in place and functioning properly. This includes checking that emergency stop buttons are easily accessible and that all guards and shields are in place to prevent contact with moving parts. Operators should also be trained on how to safely operate the machine line and what to do in case of an emergency.

When filling and sealing cans with super glue, operators should be mindful of the potential for spills or leaks. It is important to work in a well-ventilated area to prevent the buildup of fumes and to have spill kits on hand in case of any accidents. Operators should also be trained on how to properly clean up spills and leaks to prevent them from spreading and causing further hazards.

In addition to wearing PPE and following safety protocols, operators should also be aware of the potential for explosions when working with super glue. Super glue is a highly flammable material, and any sparks or heat sources near the filling and sealing machine line could ignite the fumes and cause an explosion. Operators should be trained on how to safely handle super glue and how to prevent ignition sources from coming into contact with the material.

Regular maintenance and inspections of the explosion-proof super glue can filling and sealing machine line are also essential for ensuring safe operation. Operators should regularly check for any signs of wear or damage to the machinery and report any issues to maintenance personnel immediately. Keeping the machine line in good working condition will help prevent accidents and ensure the safety of operators.

In conclusion, operating an explosion-proof super glue can filling and sealing machine line requires strict adherence to safety measures to prevent accidents and ensure the well-being of operators. By wearing appropriate PPE, following safety protocols, and being aware of the potential hazards of working with super glue, operators can safely and efficiently fill and seal cans with this hazardous material. Regular maintenance and inspections of the machinery are also essential for preventing accidents and ensuring safe operation.