Understanding the Different Types of Liquid Filling Machines

Liquid filling machines are essential equipment in various industries that deal with liquids, such as pharmaceuticals, food and beverage, cosmetics, and chemicals. These machines are designed to efficiently fill containers with liquid products, ensuring accuracy and consistency in the filling process. There are several types of liquid filling machines available on the market, each with its own unique features and capabilities. In this article, we will explore the different types of liquid filling machines and their applications.

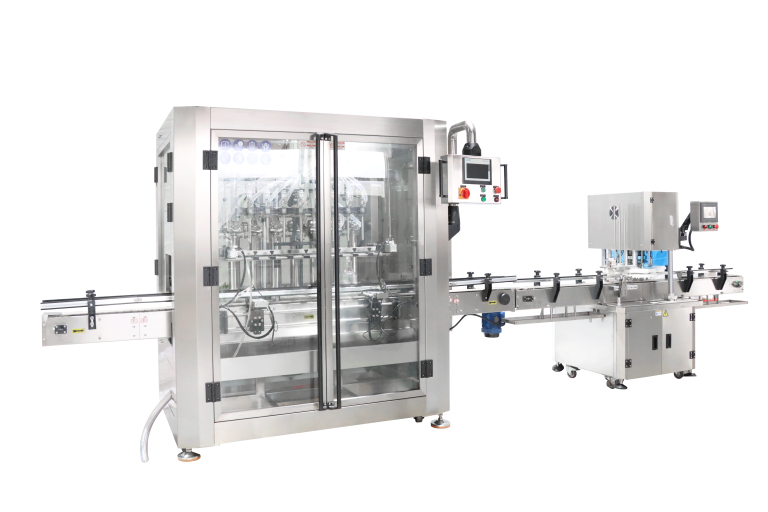

One of the most common types of liquid filling machines is the piston filler. Piston fillers are versatile machines that can handle a wide range of liquid viscosities, from thin liquids like water to thick pastes like peanut butter. These machines use a piston mechanism to draw liquid from a reservoir and dispense it into containers. Piston fillers are ideal for filling products that require precise measurements, such as pharmaceuticals and cosmetics.

Another popular type of liquid filling machine is the gravity filler. Gravity fillers rely on the force of gravity to fill containers with liquid. These machines are simple in design and are suitable for filling thin liquids that do not require precise measurements. Gravity fillers are commonly used in industries such as food and beverage, where speed and efficiency are essential.

For products that are sensitive to air or require a sterile filling environment, a vacuum filler may be the best option. Vacuum fillers work by creating a vacuum in the container before filling it with liquid. This process helps to remove air from the container, preventing oxidation and contamination of the product. Vacuum fillers are commonly used in the pharmaceutical and cosmetic industries, where product quality and safety are top priorities.

In industries where high-speed production is required, rotary fillers are often used. Rotary fillers are designed to fill multiple containers simultaneously, increasing efficiency and productivity. These machines can handle a wide range of container sizes and shapes, making them ideal for industries that produce a variety of products. Rotary fillers are commonly used in the food and beverage industry, where large quantities of liquid products need to be filled quickly.

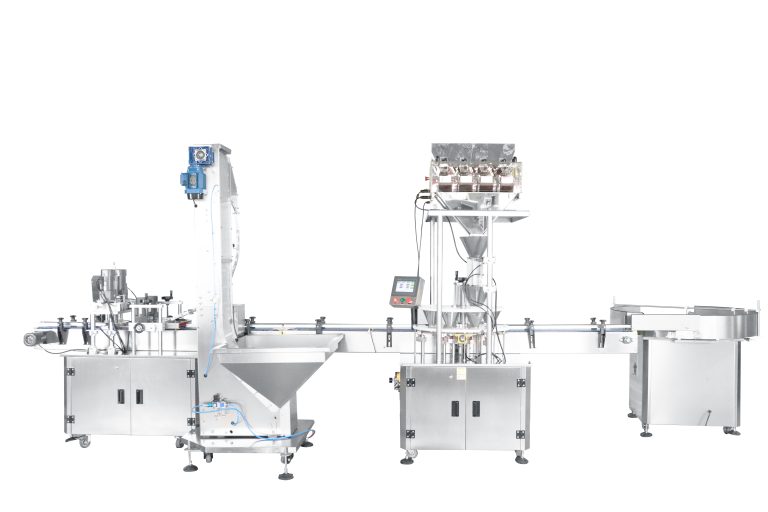

In addition to the types of liquid filling machines mentioned above, there are also specialized machines designed for specific applications. For example, a volumetric filler is used for filling containers with a specific volume of liquid, while a net weight filler is used for filling containers based on weight. These specialized machines are ideal for industries that require precise measurements and accuracy in the filling process.

Overall, the choice of liquid filling machine will depend on the specific requirements of the industry and the type of product being filled. It is essential to consider factors such as liquid viscosity, container size, production speed, and product sensitivity when selecting a liquid filling machine. By understanding the different types of liquid filling machines available, industries can choose the right machine to meet their production needs and ensure the quality and consistency of their liquid products.