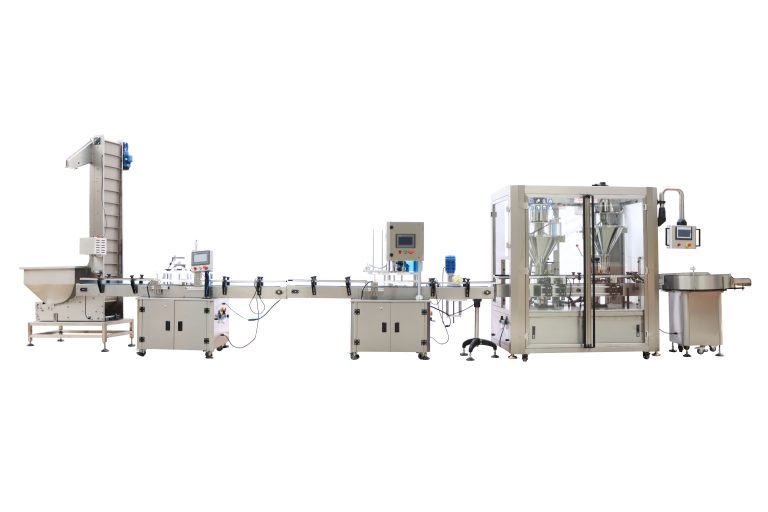

In the world of milk powder packaging, the plastic cover capping machines produced by China factories are making a significant impact.

These machines are a testament to China’s manufacturing excellence. They are engineered with precision and innovation to meet the specific requirements of the milk powder industry.

One of the key features of these capping machines is their high speed and efficiency. They can cap a large number of milk powder cans in a short period, ensuring a smooth and rapid production process. This is crucial for meeting the ever-growing demand for milk powder products.

The quality of the capping is top-notch. The machines apply the plastic covers with perfect alignment and tightness, preventing any leakage or contamination and preserving the freshness and safety of the milk powder inside.

China factories are known for their focus on technological advancements, and these capping machines are no exception. They are equipped with intelligent control systems that allow for easy operation and monitoring. This enables operators to make quick adjustments and ensures consistent performance.

The machines are also highly customizable to accommodate different can sizes and shapes, giving manufacturers the flexibility to adapt to changing market demands.

In terms of durability, they are built to last. Made from high-quality materials and components, these capping machines can withstand the continuous operation of a busy production line, reducing the need for frequent maintenance and replacements.

Moreover, the cost-effectiveness of these plastic cover capping machines from China factories makes them an attractive option for businesses worldwide. They offer excellent value for money without compromising on quality or performance.

Stay tuned to our blogs for more detailed insights into the latest developments and innovations in packaging machinery from China’s leading factories!