In the world of packaging, the automatic liquid can packaging line is a game-changer. This advanced system is designed to handle the entire process of packaging liquids with speed, precision, and consistency.

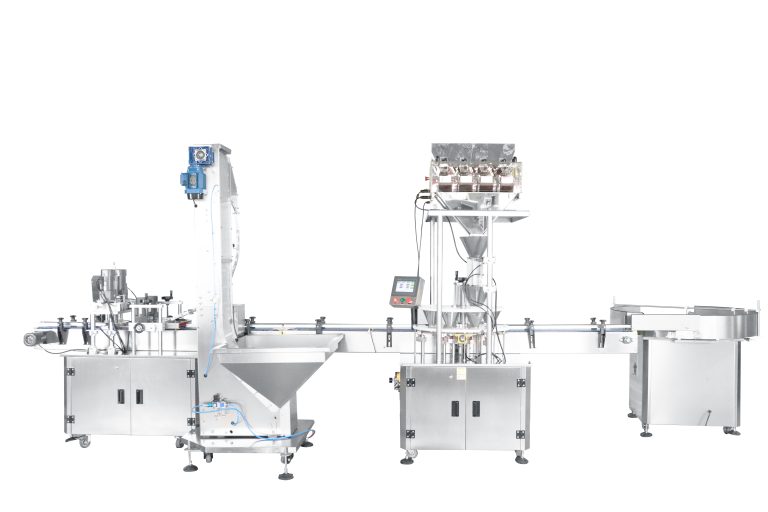

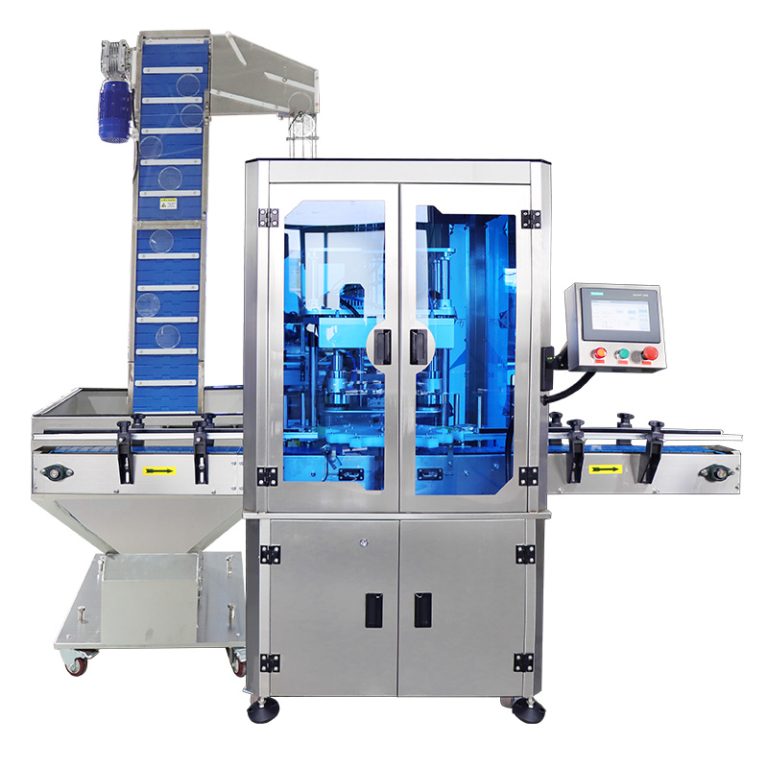

One of the standout features of the automatic liquid can packaging line is its seamless integration of multiple steps. From filling the cans with the liquid product to sealing, labeling, and palletizing, every operation is carried out smoothly and efficiently. This eliminates the need for manual handling between different stages, reducing the risk of errors and contamination.

The filling process is highly accurate, ensuring that each can contains the exact amount of liquid specified. This not only guarantees product quality but also complies with regulatory standards. The sealing mechanism is robust, providing a tight and leak-proof seal to preserve the contents and extend the shelf life of the product.

The labeling equipment within the packaging line ensures that labels are applied neatly and precisely, with clear and accurate information. This enhances the product’s marketability and helps consumers make informed choices.

The speed at which the automatic liquid can packaging line operates is remarkable. It can handle a large volume of liquid cans in a short period, allowing manufacturers to meet high production demands and deadlines.

The line is also designed for easy maintenance and troubleshooting. Regular inspections and servicing can keep it running smoothly, minimizing downtime and maximizing productivity.

In conclusion, the automatic liquid can packaging line is a state-of-the-art solution that combines efficiency, accuracy, and quality. It enables businesses to deliver liquid products to the market in a timely and professional manner, meeting the expectations of both consumers and industry standards.

Stay tuned to our blogs for more in-depth coverage and updates on the latest advancements in packaging technology!