Automatic round bottle labeling machines bring about a remarkable improvement in packaging efficiency through several key ways.

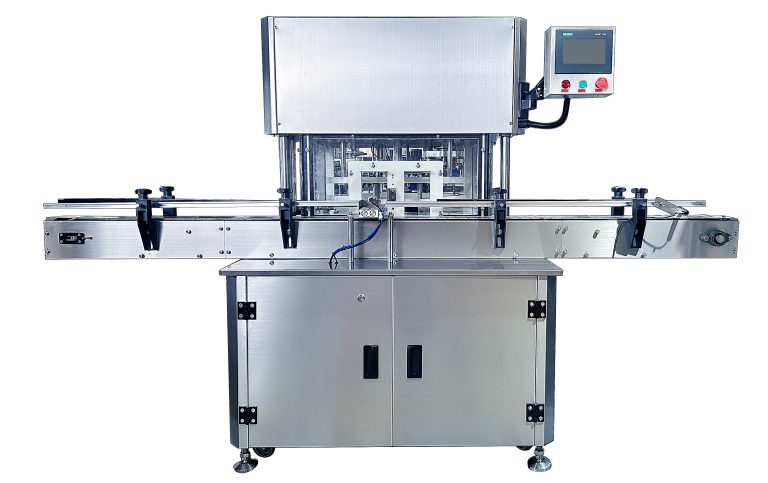

Firstly, they significantly increase the speed of the labeling process. These machines can apply labels to multiple bottles simultaneously or at a rapid pace, far outpacing manual labeling efforts. This means a higher volume of bottles can be labeled in a shorter period, reducing production time and meeting tight deadlines.

The accuracy and consistency of labeling are greatly enhanced. Automatic machines ensure that each label is placed precisely in the correct position, with the same alignment and tension every time. This eliminates errors and rework, saving valuable time and resources.

They minimize downtime and disruptions. Unlike manual operations that are prone to fatigue and breaks, automatic machines can operate continuously for extended periods without significant pauses, maximizing productivity.

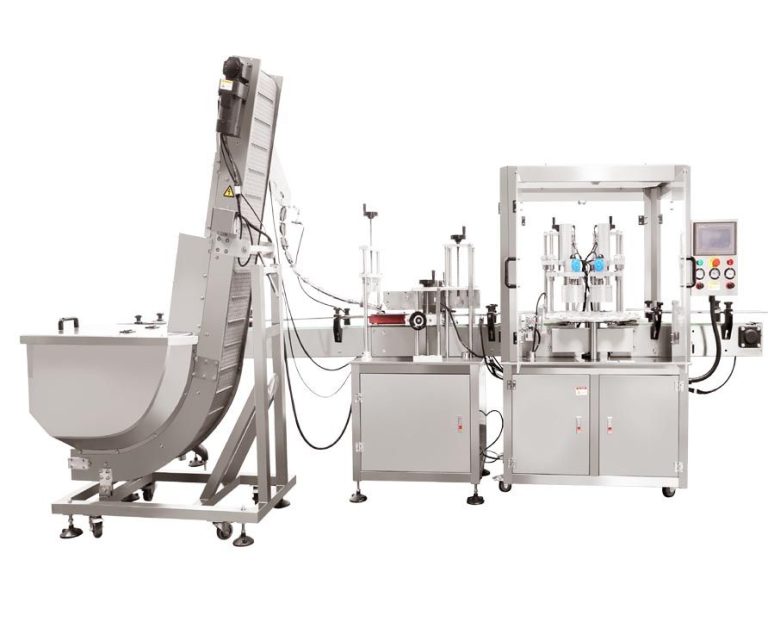

The integration of these machines into the packaging line is seamless. They can be synchronized with other equipment, such as filling and capping machines, creating a smooth and uninterrupted workflow.

Automatic round bottle labeling machines also reduce the need for extensive training and supervision of workers. Once set up and calibrated, they operate with minimal human intervention, allowing staff to focus on other important tasks within the packaging process.

Furthermore, these machines often come with advanced control systems that allow for quick adjustments and changes in label designs or bottle specifications, ensuring flexibility and adaptability without causing significant delays.

In summary, the combination of increased speed, improved accuracy, reduced downtime, seamless integration, and flexibility makes automatic round bottle labeling machines a powerful tool for boosting packaging efficiency and overall productivity.