Table of Contents

Benefits of Using an Automatic Screw Capping Machine for Bottling Processes

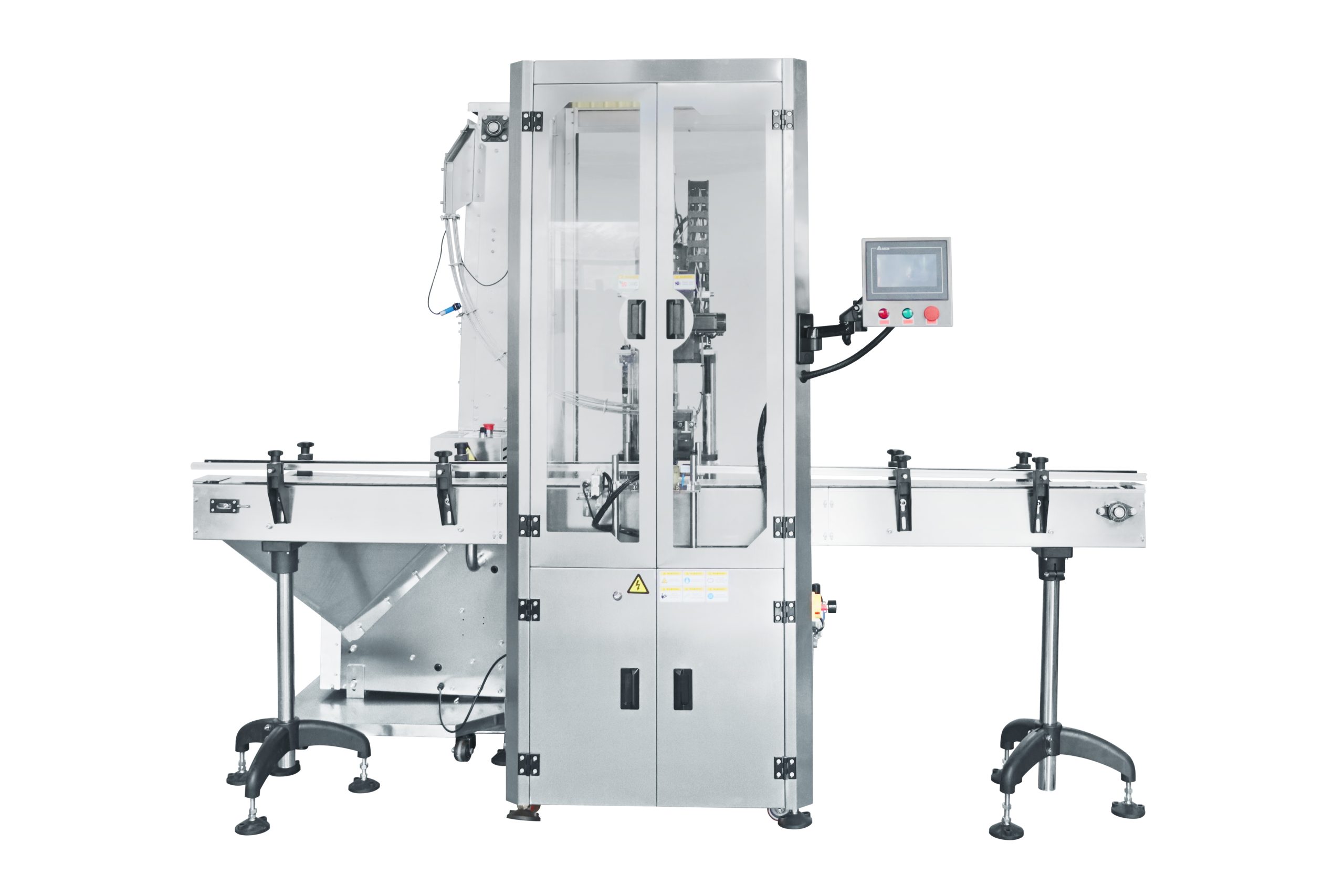

In the world of bottling processes, efficiency and precision are key factors in ensuring a successful operation. One way to elevate your bottling process is by incorporating an automatic screw capping machine into your production line. This innovative piece of equipment offers a range of benefits that can streamline your operations and improve the overall quality of your bottled products.

One of the primary advantages of using an automatic screw capping machine is its ability to increase the speed and consistency of the capping process. Manual capping can be time-consuming and prone to errors, leading to inconsistencies in the tightness of the caps and potential leaks in the bottles. With an automatic screw capping machine, you can achieve a higher level of precision and efficiency, ensuring that each bottle is securely sealed with the correct amount of torque.

Another benefit of using an automatic screw capping machine is its versatility. These machines are designed to accommodate a wide range of bottle sizes and cap types, making them suitable for a variety of bottling applications. Whether you are bottling beverages, pharmaceuticals, or cosmetics, an automatic screw capping machine can be easily adjusted to meet your specific requirements.

In addition to improving the speed and consistency of the capping process, automatic screw capping machines also offer a higher level of hygiene and safety. Manual capping can expose the product to contaminants and increase the risk of cross-contamination. By automating the capping process, you can minimize the risk of contamination and ensure that your products meet the highest standards of quality and safety.

Furthermore, automatic screw capping machines are designed to be user-friendly and easy to operate. With intuitive controls and minimal maintenance requirements, these machines can be seamlessly integrated into your production line without disrupting your workflow. This allows you to focus on other aspects of your bottling process while the machine takes care of the capping operation.

In conclusion, incorporating an automatic screw capping machine into your bottling process can offer a range of benefits that can help you streamline your operations and improve the overall quality of your products. From increased speed and consistency to enhanced hygiene and safety, these machines are a valuable investment for any bottling operation looking to elevate their production process. With their versatility and user-friendly design, automatic screw capping machines are a cost-effective solution that can help you achieve greater efficiency and precision in your bottling processes.

How to Choose the Right Automatic Screw Capping Machine for Your Bottling Line

In the world of bottling and packaging, efficiency and precision are key factors in ensuring a successful operation. One crucial piece of equipment that can greatly enhance the bottling process is the automatic screw capping machine. This machine is designed to securely seal bottles with screw caps, providing a tight and consistent seal that helps maintain product freshness and integrity.

When it comes to choosing the right automatic screw capping machine for your bottling line, there are several factors to consider. One of the most important considerations is the speed and capacity of the machine. Depending on the size of your operation and the volume of bottles you need to cap, you will need to choose a machine that can keep up with your production demands.

Another important factor to consider is the type of bottles and caps you will be using. Automatic screw capping machines come in a variety of configurations to accommodate different bottle sizes and cap styles. It is essential to choose a machine that is compatible with the specific bottles and caps you will be using to ensure a proper seal every time.

In addition to speed and compatibility, it is also important to consider the level of automation and customization that you require. Some automatic screw capping machines offer advanced features such as automatic cap sorting and feeding, torque adjustment, and cap presence detection. These features can help streamline the bottling process and ensure consistent results.

When selecting an automatic screw capping machine, it is also important to consider the overall reliability and durability of the machine. Look for a machine that is built with high-quality materials and components to ensure long-term performance and minimal downtime. Additionally, consider the level of technical support and maintenance services offered by the manufacturer to ensure that your machine remains in optimal working condition.

In conclusion, choosing the right automatic screw capping machine for your bottling line is a critical decision that can greatly impact the efficiency and quality of your operation. By considering factors such as speed, compatibility, automation, and reliability, you can select a machine that meets your specific needs and helps elevate your bottling process to new heights. With the right automatic screw capping machine in place, you can streamline your operation, improve product quality, and ultimately achieve greater success in the competitive bottling industry.