Table of Contents

Benefits of Using a Coffee Powder Canning Production Line

Coffee powder canning production lines are essential for businesses looking to streamline their coffee production process. These production lines offer a range of benefits that can help improve efficiency, quality, and overall output. In this article, we will explore some of the key advantages of using a coffee powder canning production line.

One of the main benefits of using a coffee powder canning production line is increased efficiency. These production lines are designed to automate the canning process, reducing the need for manual labor and speeding up production times. This can help businesses increase their output and meet customer demand more effectively. By automating the canning process, businesses can also reduce the risk of human error, ensuring that each can is filled accurately and consistently.

In addition to increased efficiency, coffee powder canning production lines can also help improve the quality of the final product. These production lines are equipped with advanced technology that can accurately measure and dispense the correct amount of coffee powder into each can. This helps ensure that each can contains the right amount of coffee, resulting in a consistent and high-quality product. By maintaining quality control throughout the canning process, businesses can produce coffee powder that meets the expectations of their customers.

Another benefit of using a coffee powder canning production line is cost savings. While investing in a production line may require an initial upfront investment, the long-term cost savings can be significant. By automating the canning process, businesses can reduce the need for manual labor, saving on labor costs. Additionally, the increased efficiency of a production line can help businesses reduce waste and improve overall productivity, leading to further cost savings over time.

Furthermore, using a coffee powder canning production line can also help businesses improve their overall production capacity. These production lines are designed to handle large volumes of coffee powder, allowing businesses to scale up their production as needed. This can be particularly beneficial for businesses experiencing growth or looking to expand their operations. By investing in a production line, businesses can increase their capacity and meet the demands of a growing market.

Overall, the benefits of using a coffee powder canning production line are clear. From increased efficiency and improved quality to cost savings and increased production capacity, these production lines offer a range of advantages for businesses in the coffee industry. By investing in a production line, businesses can streamline their production process, improve their product quality, and ultimately, increase their bottom line. If you are in the coffee industry and looking to take your production to the next level, consider investing in a coffee powder canning production line today.

How to Optimize Efficiency in Coffee Powder Canning Production Line

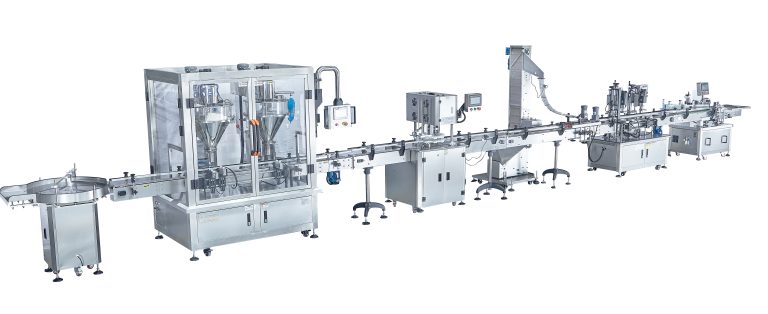

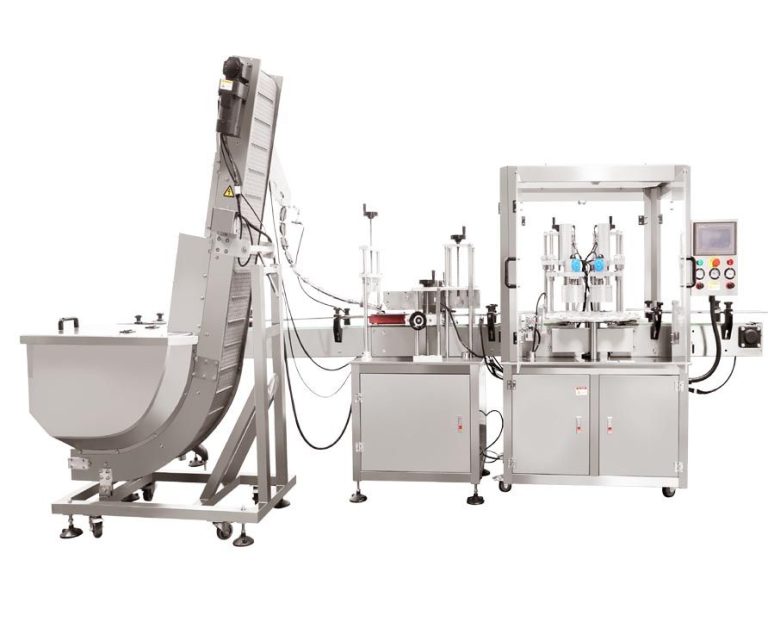

Coffee powder canning production lines are essential for efficiently packaging coffee powder for distribution and sale. These production lines consist of various machines and equipment that work together to fill, seal, and label cans of coffee powder. To ensure optimal efficiency in a coffee powder canning production line, it is important to consider several factors such as machine maintenance, production scheduling, and quality control.

One of the key factors in optimizing efficiency in a coffee powder canning production line is regular maintenance of the machines and equipment. Regular maintenance helps prevent breakdowns and downtime, which can significantly impact production output. It is important to follow the manufacturer’s recommended maintenance schedule for each machine and equipment in the production line. This includes cleaning, lubricating, and replacing worn-out parts as needed. By keeping the machines in good working condition, you can minimize disruptions and ensure smooth operation of the production line.

Another important aspect of optimizing efficiency in a coffee powder canning production line is effective production scheduling. Proper production scheduling involves planning the production process to maximize output while minimizing waste and downtime. This includes coordinating the production of coffee powder with the availability of raw materials, packaging materials, and manpower. By creating a detailed production schedule and adhering to it, you can ensure that the production line operates at maximum capacity and meets production targets.

Quality control is also crucial in optimizing efficiency in a coffee powder canning production line. Quality control measures help ensure that the coffee powder cans meet the required standards for taste, aroma, and appearance. This includes conducting regular quality checks throughout the production process, from filling and sealing the cans to labeling and packaging. By implementing strict quality control measures, you can identify and address any issues that may affect the quality of the final product, thereby reducing waste and rework.

In addition to machine maintenance, production scheduling, and quality control, there are other ways to optimize efficiency in a coffee powder canning production line. One such way is to invest in automation technology. Automation technology can help streamline the production process by reducing manual labor and increasing production speed. This can result in higher production output and lower production costs. By incorporating automation technology into the production line, you can improve efficiency and competitiveness in the market.

Furthermore, training and development of production line staff are essential for optimizing efficiency. Well-trained staff can operate the machines and equipment effectively, troubleshoot issues, and ensure that production targets are met. By providing ongoing training and development opportunities for production line staff, you can improve their skills and knowledge, leading to increased productivity and efficiency in the production line.

In conclusion, optimizing efficiency in a coffee powder canning production line requires a combination of factors such as machine maintenance, production scheduling, quality control, automation technology, and staff training. By implementing these strategies, you can improve the overall efficiency of the production line, increase production output, and reduce costs. Ultimately, optimizing efficiency in a coffee powder canning production line is essential for meeting customer demand, maintaining product quality, and staying competitive in the market.