Table of Contents

Benefits of Investing in a Complete Filling Line for Milk Powder

When it comes to packaging milk powder, having a complete filling line can offer numerous benefits for manufacturers. Investing in a complete filling line can streamline the production process, improve efficiency, and ensure consistent quality in the final product. In this article, we will explore the benefits of choosing a complete filling line for milk powder.

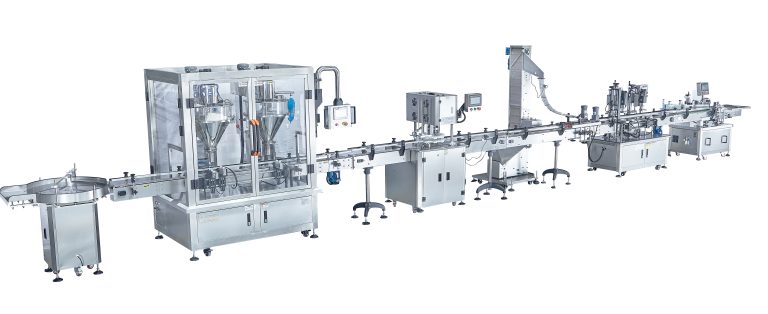

One of the key advantages of investing in a complete filling line is the ability to automate the packaging process. With a complete filling line, manufacturers can automate the filling, sealing, and labeling of milk powder containers, reducing the need for manual labor and increasing production efficiency. Automation also helps to minimize the risk of human error, ensuring that each container is filled accurately and consistently.

In addition to automation, a complete filling line can also help manufacturers to increase their production capacity. By streamlining the packaging process, manufacturers can produce more milk powder in a shorter amount of time, allowing them to meet the demands of their customers more effectively. This increased production capacity can also help manufacturers to reduce lead times and improve overall customer satisfaction.

Another benefit of investing in a complete filling line is the ability to ensure product quality and safety. A complete filling line can be equipped with advanced technology and quality control systems to monitor the filling process and detect any potential issues. This can help manufacturers to identify and address quality issues quickly, ensuring that each container of milk powder meets the highest standards of quality and safety.

Furthermore, a complete filling line can also help manufacturers to reduce waste and minimize product loss. By automating the packaging process, manufacturers can minimize the risk of spills, leaks, and other issues that can lead to product loss. This can help to improve overall efficiency and reduce costs associated with wasted product.

In addition to these benefits, investing in a complete filling line can also help manufacturers to improve their overall sustainability. By reducing the need for manual labor and minimizing product loss, manufacturers can reduce their environmental impact and operate more sustainably. This can help to enhance the reputation of the brand and attract environmentally conscious consumers.

Overall, choosing a complete filling line for milk powder can offer numerous benefits for manufacturers. From automation and increased production capacity to improved product quality and sustainability, a complete filling line can help manufacturers to streamline their packaging process and enhance their overall efficiency. By investing in a complete filling line, manufacturers can position themselves for success in the competitive milk powder market and meet the demands of their customers effectively.

Key Factors to Consider When Choosing a Filling Line for Milk Powder

When it comes to choosing a complete filling line for milk powder, there are several key factors that need to be taken into consideration. From the type of packaging to the speed and efficiency of the line, each aspect plays a crucial role in ensuring that the filling process is smooth and seamless. In this article, we will discuss some of the key factors that you should consider when selecting a filling line for milk powder.

One of the first things to consider when choosing a filling line for milk powder is the type of packaging that you will be using. There are several different types of packaging options available, including bags, pouches, and bottles. Each type of packaging has its own set of advantages and disadvantages, so it is important to carefully consider which option will work best for your specific needs. For example, bags are often more cost-effective and easier to transport, while bottles may offer better protection against moisture and contamination.

Another important factor to consider when choosing a filling line for milk powder is the speed and efficiency of the line. The speed at which the line can fill and package the milk powder will directly impact the overall productivity of your operation. A faster filling line will allow you to fill more product in a shorter amount of time, increasing your output and potentially reducing labor costs. However, it is also important to consider the quality of the fill and ensure that the line is capable of accurately measuring and dispensing the correct amount of milk powder into each package.

In addition to speed and efficiency, it is also important to consider the overall reliability and durability of the filling line. A reliable filling line will help to minimize downtime and reduce the risk of costly repairs or replacements. Look for a filling line that is made from high-quality materials and has a proven track record of performance in similar applications. It is also a good idea to choose a filling line from a reputable manufacturer that offers a warranty or guarantee on their products.

When selecting a filling line for milk powder, it is also important to consider the level of automation that is required for your operation. Fully automated filling lines can help to streamline the production process and reduce the need for manual labor. However, they may also require a larger upfront investment and more complex maintenance procedures. On the other hand, semi-automated filling lines may offer a more cost-effective solution for smaller operations that do not require a high level of automation.

Finally, it is important to consider the overall cost of the filling line, including both the initial purchase price and ongoing maintenance and operating costs. It is important to carefully evaluate the total cost of ownership for each filling line option and consider factors such as energy efficiency, maintenance requirements, and the availability of spare parts. By carefully considering all of these factors, you can choose a complete filling line for milk powder that meets your specific needs and helps to optimize the efficiency and productivity of your operation.

Comparison of Different Types of Filling Lines for Milk Powder

When it comes to packaging milk powder, choosing the right filling line is crucial to ensure efficiency and quality. There are several types of filling lines available on the market, each with its own set of features and benefits. In this article, we will compare different types of filling lines for milk powder to help you make an informed decision.

One of the most common types of filling lines for milk powder is the auger filling line. This type of filling line uses an auger screw to dispense a precise amount of powder into each container. Auger filling lines are known for their accuracy and consistency, making them ideal for high-volume production. However, they can be slower than other types of filling lines, which may not be suitable for all production needs.

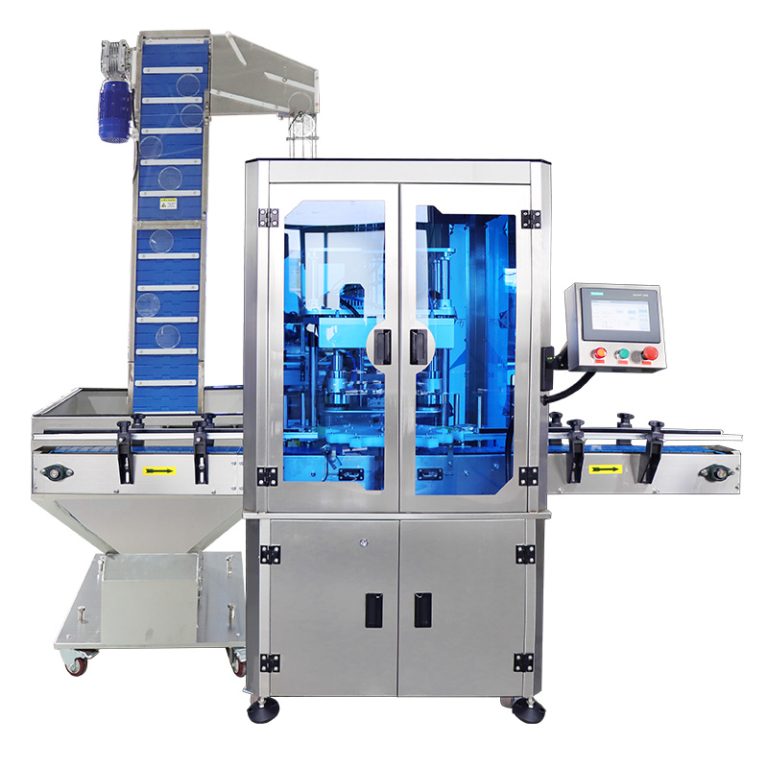

Another popular option is the rotary filling line. Rotary filling lines use a rotating carousel to move containers through the filling process. This type of filling line is known for its high speed and efficiency, making it ideal for large-scale production. However, rotary filling lines can be more complex and expensive than other types of filling lines, so they may not be suitable for smaller operations.

Gravity filling lines are another option for packaging milk powder. Gravity filling lines use the force of gravity to dispense powder into containers. This type of filling line is simple and cost-effective, making it a popular choice for smaller operations. However, gravity filling lines may not be as accurate or consistent as other types of filling lines, so they may not be suitable for high-volume production.

In addition to these types of filling lines, there are also semi-automatic and fully automatic filling lines available. Semi-automatic filling lines require some manual intervention to operate, while fully automatic filling lines are completely automated. The choice between semi-automatic and fully automatic filling lines will depend on your production needs and budget.

When choosing a filling line for milk powder, it is important to consider factors such as production volume, speed, accuracy, and cost. It is also important to consider the specific requirements of your product, such as the type of container and the type of powder being packaged. By carefully evaluating these factors, you can choose a filling line that meets your needs and helps you achieve your production goals.

In conclusion, there are several types of filling lines available for packaging milk powder, each with its own set of features and benefits. By comparing different types of filling lines and considering factors such as production volume, speed, accuracy, and cost, you can choose a filling line that meets your needs and helps you achieve your production goals. Whether you opt for an auger filling line, a rotary filling line, a gravity filling line, or a semi-automatic or fully automatic filling line, choosing the right filling line is essential for ensuring efficiency and quality in your production process.