Table of Contents

Benefits of Automating Cereal Packaging Lines

In today’s fast-paced world, efficiency and productivity are key factors in the success of any business. This is especially true in the food industry, where consumer demand for convenience and variety continues to grow. One area where automation can make a significant impact is in cereal packaging lines. By automating the packaging process, companies can streamline operations, increase output, and improve overall product quality.

One of the primary benefits of automating cereal packaging lines is the increase in efficiency. Manual packaging processes are often slow and labor-intensive, requiring a significant amount of time and resources to complete. By automating these processes, companies can significantly reduce the time it takes to package their products, allowing them to produce more in less time. This not only increases output but also reduces labor costs, as fewer workers are needed to operate the packaging line.

Another key benefit of automating cereal packaging lines is the improvement in product quality. Manual packaging processes are prone to human error, which can result in inconsistencies in packaging and product quality. By automating the packaging process, companies can ensure that each package is filled accurately and sealed properly, reducing the risk of product defects and recalls. This not only improves the overall quality of the product but also enhances consumer satisfaction and brand reputation.

Automation also allows companies to better track and monitor the packaging process. By integrating sensors and monitoring systems into the packaging line, companies can collect real-time data on production rates, packaging quality, and equipment performance. This data can be used to identify bottlenecks in the production process, optimize packaging efficiency, and make informed decisions to improve overall operations. Additionally, automation allows companies to implement quality control measures, such as weight checks and barcode scanning, to ensure that each package meets the required standards.

Furthermore, automating cereal packaging lines can help companies meet the growing demand for sustainable packaging solutions. With increasing consumer awareness of environmental issues, companies are under pressure to reduce their carbon footprint and minimize waste. Automated packaging lines can be designed to use eco-friendly materials, such as recyclable or biodegradable packaging, and optimize packaging efficiency to reduce material waste. This not only benefits the environment but also appeals to environmentally conscious consumers, giving companies a competitive edge in the market.

In conclusion, automating cereal packaging lines offers numerous benefits for companies in the food industry. From increased efficiency and improved product quality to better tracking and monitoring capabilities, automation can help companies streamline operations, increase output, and meet consumer demand for sustainable packaging solutions. By investing in automated packaging technology, companies can stay ahead of the competition, reduce costs, and enhance their overall business performance.

Top Tips for Optimizing Efficiency in Cereal Can Packing Lines

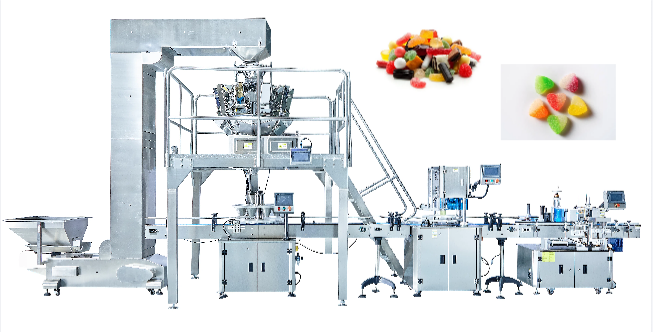

Cereal can packing lines are an essential component of the food packaging industry, ensuring that cereals are efficiently and effectively packaged for distribution to consumers. Optimizing efficiency in cereal can packing lines is crucial for maximizing productivity and reducing costs. There are several top tips that can help companies achieve this goal.

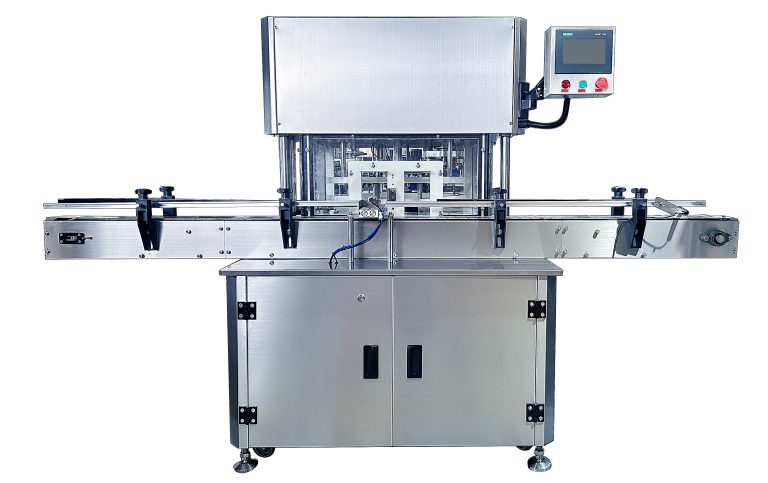

One key tip for optimizing efficiency in cereal can packing lines is to invest in high-quality equipment. The quality of the packing line equipment can have a significant impact on the overall efficiency of the line. Investing in state-of-the-art machinery that is designed for high-speed and precision can help to streamline the packing process and minimize downtime. Regular maintenance and servicing of the equipment are also essential to ensure that it operates at peak performance.

Another important tip for optimizing efficiency in cereal can packing lines is to implement automation wherever possible. Automation can help to reduce the need for manual labor, increase the speed of the packing process, and improve overall accuracy. By automating tasks such as filling, sealing, and labeling, companies can significantly increase their packing line efficiency. Additionally, automation can help to reduce the risk of human error and ensure consistent quality in the packaged products.

Efficient planning and organization are also crucial for optimizing efficiency in cereal can packing lines. Companies should carefully plan the layout of the packing line to minimize unnecessary movement and maximize the flow of materials. By organizing the packing line in a logical and efficient manner, companies can reduce bottlenecks and improve overall productivity. Additionally, companies should establish clear procedures and protocols for each step of the packing process to ensure that employees are working efficiently and effectively.

Regular monitoring and analysis of key performance indicators (KPIs) are essential for optimizing efficiency in cereal can packing lines. Companies should track metrics such as packing speed, downtime, and error rates to identify areas for improvement. By analyzing KPIs regularly, companies can identify trends, pinpoint inefficiencies, and implement targeted solutions to optimize their packing line efficiency. Continuous improvement is key to maximizing efficiency in cereal can packing lines.

Effective communication and collaboration among team members are also critical for optimizing efficiency in cereal can packing lines. Clear communication between operators, supervisors, and maintenance staff can help to identify and address issues quickly, minimizing downtime and maximizing productivity. Collaboration between different departments, such as production, quality control, and maintenance, can also help to streamline the packing process and improve overall efficiency.

In conclusion, optimizing efficiency in cereal can packing lines is essential for maximizing productivity and reducing costs. By investing in high-quality equipment, implementing automation, planning and organizing effectively, monitoring KPIs, and promoting effective communication and collaboration, companies can achieve significant improvements in their packing line efficiency. Continuous improvement and a commitment to excellence are key to success in the competitive food packaging industry.