Table of Contents

Benefits of Using a Canned Food Can Sealing Machine for Metal Cans

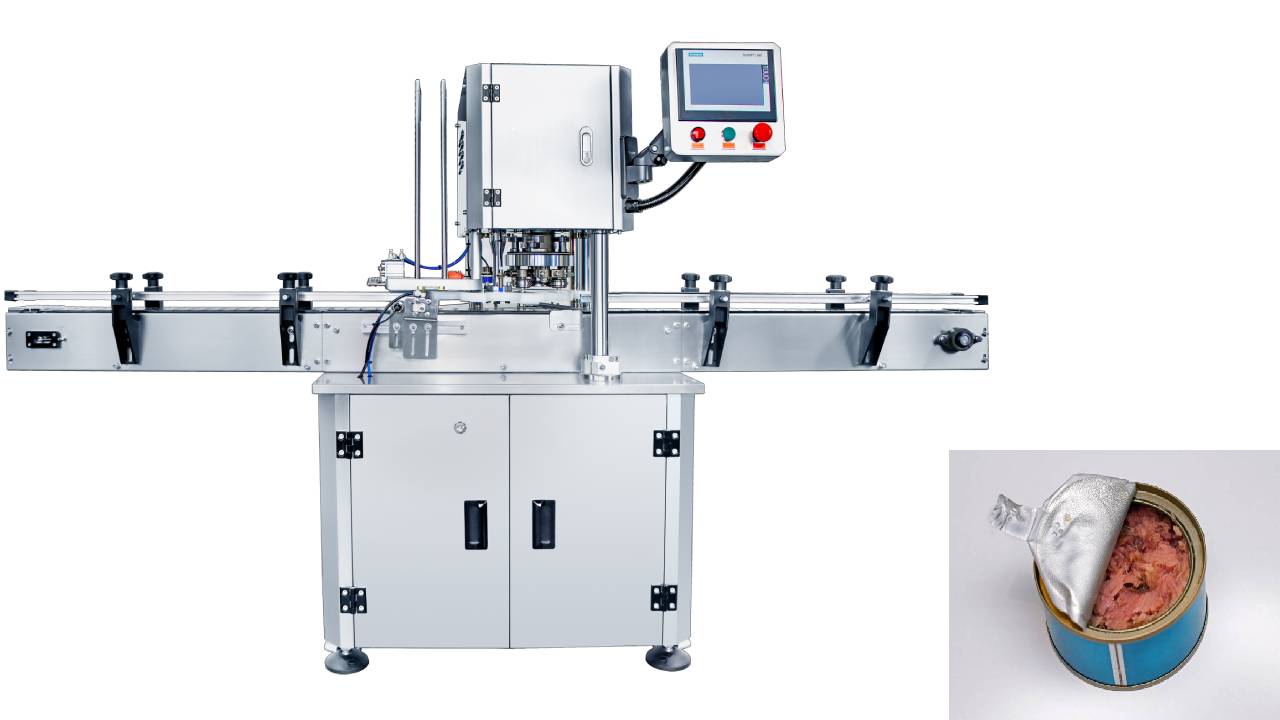

Canned food has been a staple in households for decades, providing convenience and long shelf life for a variety of food items. One crucial aspect of canned food production is the sealing of the cans to ensure the contents remain fresh and uncontaminated. In the past, this process was done manually, which was time-consuming and prone to errors. However, with advancements in technology, canned food can sealing machines have become an essential tool in the food packaging industry.

One of the primary benefits of using a canned food can sealing machine for metal cans is efficiency. These machines are designed to seal cans quickly and accurately, reducing the time and labor required for manual sealing. This not only increases productivity but also ensures a consistent seal on every can, minimizing the risk of contamination and spoilage.

Another advantage of using a canned food can sealing machine is the improved quality of the seal. These machines are equipped with advanced sealing mechanisms that create a tight and secure seal on the cans, preventing air and moisture from entering and compromising the contents. This helps to extend the shelf life of the canned food and maintain its freshness for longer periods.

In addition to efficiency and quality, canned food can sealing machines also offer versatility in sealing different sizes and types of metal cans. These machines can be adjusted to accommodate various can sizes, making them suitable for a wide range of food products. Whether you are packaging soups, vegetables, or fruits, a canned food can sealing machine can handle the job with precision and ease.

Furthermore, using a canned food can sealing machine can help reduce the risk of contamination during the sealing process. Manual sealing can be prone to human error, leading to improperly sealed cans that are vulnerable to contamination. With a sealing machine, the process is automated and controlled, minimizing the risk of contamination and ensuring the safety of the canned food products.

Moreover, canned food can sealing machines are designed to be user-friendly and easy to operate. With simple controls and settings, operators can quickly learn how to use the machine effectively, reducing the need for extensive training. This makes it easier for food packaging companies to integrate these machines into their production lines and streamline their operations.

In conclusion, the benefits of using a canned food can sealing machine for metal cans are numerous. From increased efficiency and quality to versatility and safety, these machines offer a range of advantages for food packaging companies. By investing in a high-quality sealing machine, companies can improve their production processes, reduce costs, and ensure the freshness and safety of their canned food products. With the right machine, sealing cans has never been easier or more reliable.

How to Choose the Right Canned Food Can Sealing Machine for Metal Cans

Canned food has been a staple in households for decades, providing a convenient and long-lasting option for storing and preserving food. One crucial component of the canning process is the sealing machine, which ensures that the contents of the can remain fresh and free from contamination. When it comes to sealing metal cans, choosing the right can sealing machine is essential to ensure a secure and airtight seal.

There are several factors to consider when selecting a can sealing machine for metal cans. One of the most important considerations is the size and type of cans that will be sealed. Different machines are designed to accommodate various can sizes and shapes, so it is essential to choose a machine that is compatible with the cans you will be using.

Another crucial factor to consider is the speed and efficiency of the machine. Depending on the volume of cans that need to be sealed, it is important to select a machine that can keep up with the demand. Some machines are designed for high-speed production, while others are better suited for smaller batches.

In addition to size and speed, it is also important to consider the type of seal that the machine produces. A good can sealing machine should create a strong and airtight seal to prevent spoilage and contamination. Some machines use heat sealing, while others use pressure sealing. It is important to choose a machine that is capable of producing the type of seal that best suits your needs.

When selecting a can sealing machine for metal cans, it is also important to consider the level of automation that is desired. Some machines are fully automated, requiring minimal human intervention, while others require more manual operation. The level of automation will depend on the specific needs of the production process and the available resources.

Cost is another important factor to consider when choosing a can sealing machine for metal cans. The price of a machine can vary significantly depending on its size, speed, and features. It is important to consider the long-term costs of operating the machine, including maintenance and repair expenses.

In conclusion, choosing the right can sealing machine for metal cans is essential to ensure the quality and safety of canned food products. By considering factors such as size, speed, seal type, automation level, and cost, you can select a machine that meets your specific needs and production requirements. Investing in a high-quality can sealing machine will help to ensure the success of your canning operation and the satisfaction of your customers.

Maintenance Tips for Ensuring Longevity of Your Canned Food Can Sealing Machine for Metal Cans

Canned food can sealing machines are essential equipment for food processing industries that rely on metal cans to preserve and package their products. These machines play a crucial role in ensuring the safety and quality of canned foods by securely sealing the cans to prevent contamination and spoilage. To maximize the efficiency and longevity of your canned food can sealing machine for metal cans, it is important to follow proper maintenance practices.

Regular cleaning and lubrication are key maintenance tasks that can help prevent wear and tear on your can sealing machine. Dust, debris, and food particles can accumulate on the machine’s components over time, leading to decreased performance and potential breakdowns. To avoid these issues, it is recommended to clean the machine regularly using a mild detergent and water. Be sure to dry the machine thoroughly after cleaning to prevent rusting.

In addition to cleaning, lubricating the moving parts of the can sealing machine is essential for smooth operation. Lubricants help reduce friction between components, preventing premature wear and extending the lifespan of the machine. It is important to use the correct type of lubricant recommended by the manufacturer to avoid damaging the machine. Regularly inspecting the machine for signs of wear and tear, such as loose bolts or worn seals, can help identify potential issues before they escalate.

Another important maintenance tip for ensuring the longevity of your canned food can sealing machine is to calibrate the machine regularly. Calibration ensures that the machine is operating at optimal performance levels, resulting in consistent and reliable sealing of metal cans. Improper calibration can lead to uneven sealing, leaks, and other issues that can compromise the quality of canned foods. It is recommended to calibrate the machine according to the manufacturer’s guidelines or seek professional assistance if needed.

Proper storage of the can sealing machine when not in use is also crucial for maintaining its longevity. Storing the machine in a clean, dry, and well-ventilated area can help prevent rust and corrosion, which can damage the machine’s components over time. It is important to cover the machine with a protective tarp or sheet to shield it from dust and moisture when not in use. Additionally, storing the machine in a temperature-controlled environment can help prevent damage from extreme heat or cold.

Regularly inspecting and replacing worn or damaged parts is another important maintenance tip for ensuring the longevity of your canned food can sealing machine. Over time, components such as seals, gaskets, and blades may wear out and need to be replaced to maintain the machine’s performance. It is recommended to keep a stock of spare parts on hand to quickly address any issues that may arise during operation. Following the manufacturer’s guidelines for replacing parts and conducting routine maintenance checks can help prevent costly repairs and downtime.

In conclusion, proper maintenance practices are essential for ensuring the longevity of your canned food can sealing machine for metal cans. Regular cleaning, lubrication, calibration, storage, and inspection of the machine’s components can help prevent wear and tear, extend the machine’s lifespan, and ensure consistent and reliable sealing of metal cans. By following these maintenance tips, you can maximize the efficiency and performance of your can sealing machine, ultimately leading to higher quality canned foods and increased productivity in your food processing operations.