Table of Contents

Benefits of Using Camel Milk Powder in Food Production

Camel milk powder has been gaining popularity in recent years as a nutritious and versatile ingredient in food production. With its unique composition and health benefits, camel milk powder is being used in a variety of products, from baked goods to beverages. One of the key advantages of using camel milk powder is its long shelf life and ease of storage, making it a convenient option for manufacturers looking to incorporate a healthy and sustainable ingredient into their products.

One of the main benefits of camel milk powder is its nutritional value. Camel milk is rich in vitamins, minerals, and proteins, making it a great source of essential nutrients for consumers. By using camel milk powder in food production, manufacturers can enhance the nutritional profile of their products without compromising on taste or quality. In addition, camel milk powder is lactose-free, making it a suitable option for individuals with lactose intolerance or dairy allergies.

Another advantage of using camel milk powder is its unique flavor profile. Camel milk has a slightly sweet and nutty taste, which can add depth and complexity to a variety of dishes. Whether used in baking, cooking, or as a beverage, camel milk powder can enhance the overall flavor of a product and provide a distinctive taste that sets it apart from traditional dairy products.

In addition to its nutritional and flavor benefits, camel milk powder is also known for its health-promoting properties. Camel milk is naturally high in antioxidants, which can help protect the body against oxidative stress and inflammation. By incorporating camel milk powder into their products, manufacturers can offer consumers a functional ingredient that supports overall health and well-being.

Furthermore, camel milk powder is a sustainable and environmentally friendly option for food production. Camels are well-adapted to arid climates and require less water and resources compared to traditional dairy cattle. By using camel milk powder, manufacturers can reduce their environmental impact and support sustainable farming practices.

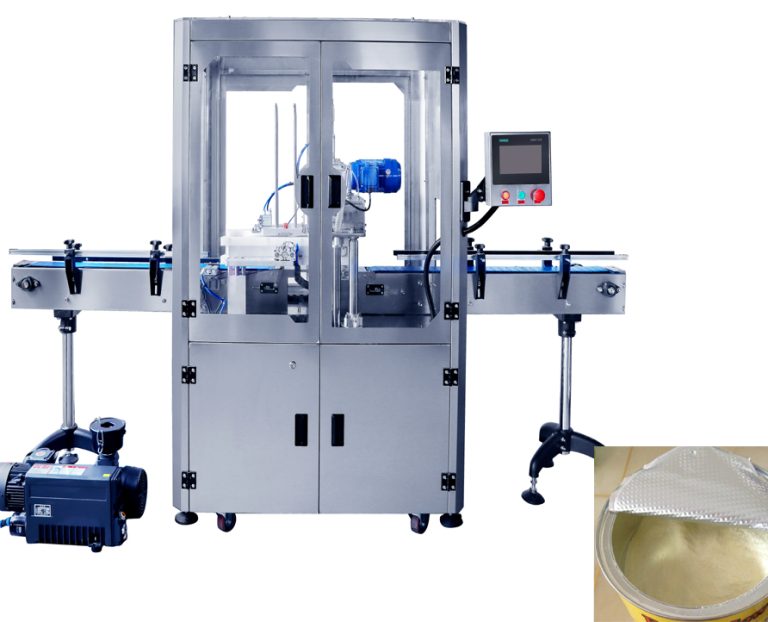

One of the challenges of using camel milk powder in food production is the need for specialized equipment to handle and process the powder. This is where a camel milk powder filling can seamer production line comes into play. A can seamer production line is designed to efficiently fill and seal cans of camel milk powder, ensuring a hygienic and safe product for consumers.

By investing in a camel milk powder filling can seamer production line, manufacturers can streamline their production process and increase efficiency. The equipment is designed to handle the unique properties of camel milk powder, ensuring a consistent and high-quality product every time. With a can seamer production line, manufacturers can meet the growing demand for camel milk powder products and expand their market reach.

In conclusion, the benefits of using camel milk powder in food production are numerous. From its nutritional value and unique flavor profile to its health-promoting properties and sustainability, camel milk powder is a versatile ingredient that can enhance a wide range of products. By investing in a camel milk powder filling can seamer production line, manufacturers can take advantage of this growing trend and offer consumers a healthy and delicious alternative to traditional dairy products.

How Can Seamer Production Line Improves Efficiency in Camel Milk Powder Filling

Camel milk has gained popularity in recent years due to its numerous health benefits and unique nutritional profile. As demand for camel milk products continues to grow, manufacturers are constantly looking for ways to improve efficiency in the production process. One key aspect of this is the use of can seamer production lines for filling camel milk powder.

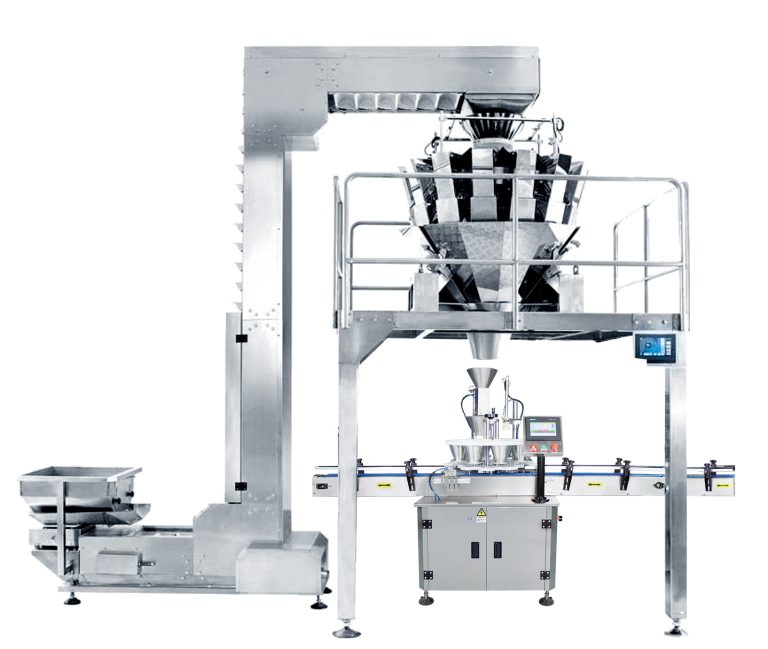

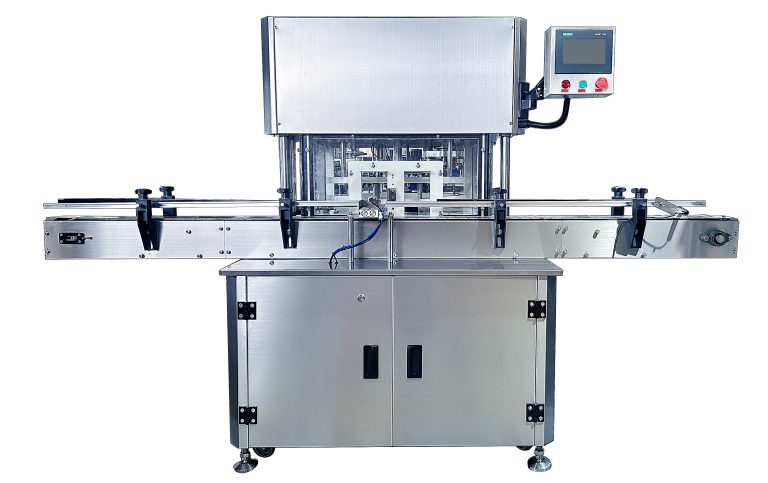

Can seamer production lines are automated systems that streamline the process of filling and sealing cans with powdered products. These machines are designed to handle high volumes of production while ensuring accuracy and consistency in the filling process. By using a can seamer production line for camel milk powder filling, manufacturers can significantly improve efficiency and productivity in their operations.

One of the main advantages of using a can seamer production line for camel milk powder filling is the speed at which the process can be completed. These machines are capable of filling and sealing hundreds of cans per minute, far surpassing the capabilities of manual filling methods. This increased speed allows manufacturers to meet the demands of a growing market without sacrificing quality or consistency in their products.

In addition to speed, can seamer production lines also offer improved accuracy in the filling process. These machines are equipped with sensors and controls that ensure precise measurements of the powdered product, reducing the risk of overfilling or underfilling cans. This level of accuracy is crucial in maintaining product quality and consistency, which is essential for meeting consumer expectations and regulatory standards.

Furthermore, can seamer production lines are designed to minimize waste in the production process. By accurately measuring and filling each can, manufacturers can reduce the amount of product that is lost or discarded due to errors in the filling process. This not only helps to improve efficiency but also contributes to cost savings for the manufacturer.

Another benefit of using a can seamer production line for camel milk powder filling is the improved hygiene and safety of the production environment. These machines are constructed with materials that are easy to clean and sanitize, reducing the risk of contamination in the production process. Additionally, the automated nature of these machines reduces the need for manual handling of the product, further minimizing the risk of contamination.

Overall, the use of a can seamer production line for camel milk powder filling offers numerous benefits for manufacturers looking to improve efficiency in their operations. From increased speed and accuracy to reduced waste and improved hygiene, these machines are a valuable investment for any manufacturer looking to streamline their production process. By incorporating a can seamer production line into their operations, manufacturers can meet the demands of a growing market while maintaining the quality and consistency of their camel milk powder products.

Sustainability and Cost-Effectiveness of Camel Milk Powder Filling Can Seamer Production Line

Camel milk has been gaining popularity in recent years due to its numerous health benefits and unique taste. As a result, there is a growing demand for camel milk products, including camel milk powder. To meet this demand, many companies are turning to camel milk powder filling can seamer production lines.

One of the key advantages of using a camel milk powder filling can seamer production line is its sustainability. Camel milk is known for being more environmentally friendly than cow’s milk, as camels require less water and food to produce milk. By using a camel milk powder filling can seamer production line, companies can further reduce their environmental impact by efficiently packaging camel milk powder in cans.

In addition to being sustainable, camel milk powder filling can seamer production lines are also cost-effective. These production lines are designed to be efficient and reliable, allowing companies to increase their production capacity while keeping costs low. By automating the filling and sealing process, companies can save on labor costs and reduce the risk of human error.

Furthermore, camel milk powder filling can seamer production lines are versatile and can be customized to meet the specific needs of each company. Whether a company is looking to fill small cans for individual consumers or large cans for bulk orders, these production lines can be adjusted to accommodate different sizes and shapes of cans.

Another benefit of using a camel milk powder filling can seamer production line is the quality of the final product. These production lines are designed to ensure that each can is filled with the correct amount of camel milk powder and sealed properly to maintain freshness and prevent contamination. This level of precision and consistency helps companies deliver high-quality products to their customers.

Overall, camel milk powder filling can seamer production lines offer a sustainable and cost-effective solution for companies looking to meet the growing demand for camel milk products. By investing in these production lines, companies can increase their production capacity, reduce their environmental impact, and deliver high-quality products to their customers.

In conclusion, camel milk powder filling can seamer production lines are a valuable asset for companies in the camel milk industry. Not only do these production lines offer sustainability and cost-effectiveness, but they also provide companies with the flexibility to customize their production process and deliver high-quality products to their customers. As the demand for camel milk products continues to grow, investing in a camel milk powder filling can seamer production line is a smart choice for companies looking to stay competitive in the market.