Table of Contents

Benefits of Using Automatic Servo Piston Type Filling Machine for Production Efficiency

In today’s fast-paced manufacturing industry, efficiency is key to staying competitive and meeting customer demands. One way to boost production efficiency is by investing in the latest technology, such as the automatic servo piston type filling machine. This cutting-edge equipment offers a range of benefits that can help streamline your production process and increase output.

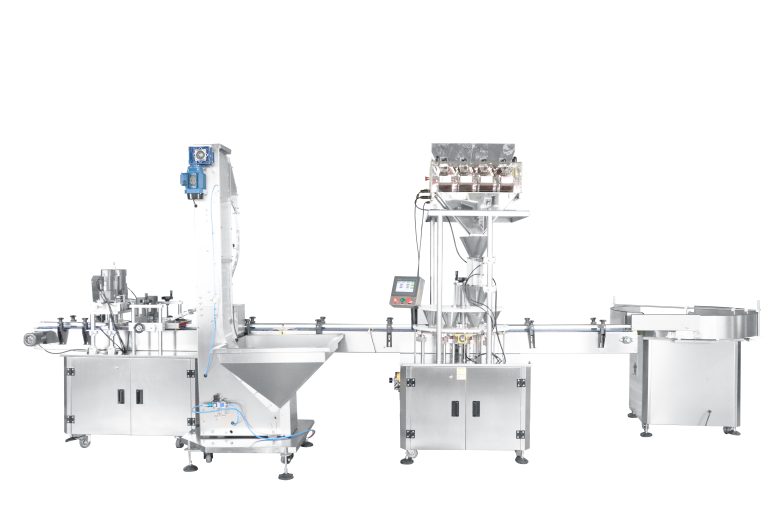

One of the main advantages of using an automatic servo piston type filling machine is its precision and accuracy. These machines are equipped with advanced servo motors that allow for precise control over the filling process. This means that you can fill containers with the exact amount of product every time, reducing waste and ensuring consistency in your final product. Whether you are filling bottles, jars, or other containers, you can trust that the automatic servo piston type filling machine will deliver accurate results.

Another benefit of using this type of filling machine is its speed and efficiency. With its automated operation, the machine can fill containers quickly and efficiently, allowing you to increase your production output without sacrificing quality. This can help you meet tight deadlines and fulfill large orders in a timely manner. By automating the filling process, you can also free up your workforce to focus on other tasks, further improving overall efficiency in your production facility.

In addition to precision and speed, automatic servo piston type filling machines are also versatile and easy to use. These machines can be easily adjusted to accommodate different container sizes and fill volumes, making them suitable for a wide range of products and production requirements. Whether you are filling liquids, creams, gels, or other substances, the machine can be customized to meet your specific needs. Furthermore, the user-friendly interface makes it easy for operators to set up and operate the machine, reducing the risk of errors and ensuring smooth operation.

Furthermore, investing in an automatic servo piston type filling machine can also lead to cost savings in the long run. By reducing waste, increasing efficiency, and improving overall productivity, you can lower production costs and improve your bottom line. Additionally, the durability and reliability of these machines mean that they require minimal maintenance and have a long lifespan, further reducing operating costs over time. With the potential for increased output and reduced expenses, the automatic servo piston type filling machine is a smart investment for any manufacturing facility looking to improve efficiency.

Overall, the automatic servo piston type filling machine offers a range of benefits that can help boost production efficiency in your facility. From precision and accuracy to speed and versatility, this advanced equipment can streamline your production process and increase output while reducing costs. By investing in the latest technology, you can stay ahead of the competition and meet the demands of today’s fast-paced manufacturing industry.

Tips for Optimizing Production Efficiency with Automatic Servo Piston Type Filling Machine

In today’s fast-paced manufacturing environment, efficiency is key to staying competitive and meeting customer demands. One way to boost production efficiency is by utilizing automatic servo piston type filling machines. These machines offer a range of benefits that can help streamline your production process and increase output. In this article, we will explore some tips for optimizing production efficiency with an automatic servo piston type filling machine.

One of the key advantages of automatic servo piston type filling machines is their precision and accuracy. These machines are equipped with servo motors that allow for precise control over the filling process, ensuring consistent fill levels and reducing product waste. To maximize the efficiency of your filling machine, it is important to calibrate the machine regularly and ensure that it is operating at optimal settings. This will help minimize downtime and ensure that your production line is running smoothly.

Another tip for optimizing production efficiency with an automatic servo piston type filling machine is to invest in training for your operators. Proper training can help your operators understand how to operate the machine effectively and troubleshoot any issues that may arise. By investing in training, you can ensure that your operators are equipped with the knowledge and skills needed to maximize the efficiency of the filling machine and keep your production line running smoothly.

In addition to training, regular maintenance is essential for keeping your automatic servo piston type filling machine in top condition. Regular maintenance can help prevent breakdowns and ensure that the machine is operating at peak performance. It is important to follow the manufacturer’s recommended maintenance schedule and address any issues promptly to avoid costly downtime. By staying on top of maintenance, you can prolong the life of your filling machine and maximize its efficiency.

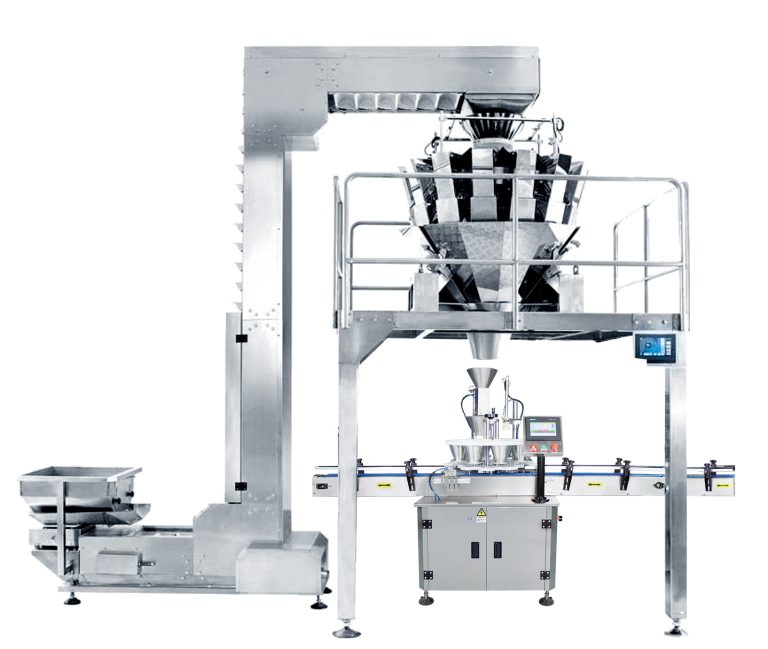

One of the key features of automatic servo piston type filling machines is their versatility. These machines can handle a wide range of products, from liquids to creams to gels, making them ideal for a variety of industries. To optimize production efficiency, it is important to choose the right filling machine for your specific needs. Consider factors such as product viscosity, fill volume, and production speed when selecting a filling machine to ensure that it can meet your production requirements.

Finally, integrating your automatic servo piston type filling machine with other automated systems can further enhance production efficiency. By connecting your filling machine to a conveyor system or packaging line, you can streamline the production process and reduce manual handling. This can help increase output and reduce the risk of errors, leading to higher overall efficiency.

In conclusion, automatic servo piston type filling machines offer a range of benefits for boosting production efficiency. By following these tips, you can optimize the performance of your filling machine and maximize your production output. Investing in training, regular maintenance, and integration with other automated systems can help you stay ahead of the competition and meet customer demands. With the right approach, an automatic servo piston type filling machine can be a valuable asset for improving efficiency in your manufacturing process.

Case Studies on Increased Production Output with Automatic Servo Piston Type Filling Machine

In today’s fast-paced manufacturing industry, efficiency is key to staying competitive and meeting customer demands. One way to boost production efficiency is by investing in the latest technology, such as the automatic servo piston type filling machine. This cutting-edge equipment offers a range of benefits that can help companies increase their production output and streamline their operations.

One of the main advantages of the automatic servo piston type filling machine is its precision and accuracy. This machine is equipped with advanced servo motors that allow for precise control over the filling process, ensuring that each product is filled to the exact specifications. This level of accuracy not only improves product quality but also reduces waste and minimizes the risk of costly errors.

Another key benefit of the automatic servo piston type filling machine is its speed and efficiency. This machine is capable of filling a large number of containers in a short amount of time, significantly increasing production output. By automating the filling process, companies can reduce the need for manual labor and free up employees to focus on other tasks, further improving overall efficiency.

In addition to precision and speed, the automatic servo piston type filling machine also offers versatility and flexibility. This machine can be easily adjusted to accommodate different container sizes and fill volumes, making it ideal for companies that produce a variety of products. With the ability to quickly change settings and switch between different products, companies can easily adapt to changing market demands and maximize their production capabilities.

One company that has experienced significant improvements in production efficiency with the automatic servo piston type filling machine is XYZ Manufacturing. Prior to investing in this equipment, XYZ Manufacturing relied on manual filling processes that were time-consuming and prone to errors. By switching to the automatic servo piston type filling machine, XYZ Manufacturing was able to increase their production output by 30% while reducing waste and improving product quality.

Another company that has seen impressive results with the automatic servo piston type filling machine is ABC Pharmaceuticals. With a growing demand for their products, ABC Pharmaceuticals needed a solution that could keep up with their production needs. By implementing the automatic servo piston type filling machine, ABC Pharmaceuticals was able to double their production output and meet customer demands without compromising on quality.

Overall, the automatic servo piston type filling machine is a valuable investment for companies looking to boost their production efficiency. With its precision, speed, versatility, and flexibility, this equipment offers a range of benefits that can help companies streamline their operations and increase their output. By investing in the latest technology, companies can stay ahead of the competition and meet the demands of today’s fast-paced manufacturing industry.