Table of Contents

Increased Efficiency and Productivity

In today’s fast-paced world, efficiency and productivity are key factors in the success of any business, especially in the food industry. With the increasing demand for packaged food products, companies are constantly looking for ways to streamline their production processes. One solution that has proven to be highly effective is the use of can packaging machine lines.

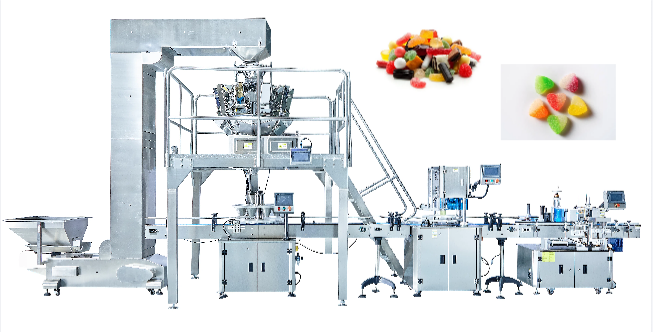

Can packaging machine lines are automated systems that can handle the entire packaging process, from filling and sealing cans to labeling and palletizing. These machines are designed to work quickly and efficiently, allowing companies to increase their output while reducing labor costs. By automating the packaging process, companies can also ensure consistency in the quality of their products, leading to higher customer satisfaction.

One of the main benefits of using a can packaging machine line is the increased efficiency it brings to the production process. These machines are capable of packaging a large number of cans in a short amount of time, far surpassing what can be achieved manually. This means that companies can meet the demands of their customers more effectively and efficiently, leading to higher profits and a stronger competitive edge in the market.

Furthermore, can packaging machine lines are designed to be versatile and adaptable to different types of food products. Whether companies are packaging canned fruits, vegetables, soups, or beverages, these machines can be easily adjusted to accommodate various sizes and shapes of cans. This flexibility allows companies to diversify their product offerings without having to invest in multiple packaging systems.

Another advantage of using a can packaging machine line is the reduction of waste and product loss. These machines are programmed to accurately fill cans with the correct amount of product, minimizing overfilling or underfilling. This not only saves companies money on raw materials but also ensures that customers receive the correct amount of product in each can. Additionally, the automated sealing process helps to prevent leaks and spoilage, further reducing product loss.

In addition to increased efficiency and reduced waste, can packaging machine lines also contribute to a safer working environment for employees. By automating the packaging process, companies can minimize the risk of injuries and accidents that may occur during manual packaging. This not only protects the well-being of employees but also helps to maintain a positive work environment and improve overall morale.

Overall, the benefits of using a can packaging machine line for food products are clear. From increased efficiency and productivity to reduced waste and improved safety, these machines offer a wide range of advantages for companies in the food industry. By investing in a can packaging machine line, companies can streamline their production processes, meet customer demands more effectively, and ultimately achieve greater success in the market.

Improved Product Quality and Consistency

In the food industry, packaging plays a crucial role in maintaining the quality and consistency of products. Can packaging machines have become increasingly popular due to their efficiency and ability to streamline the packaging process. By investing in a can packaging machine line, food manufacturers can benefit from improved product quality and consistency.

One of the key advantages of using a can packaging machine line is the precision and accuracy it offers. These machines are designed to fill cans with the exact amount of product, ensuring consistency across all packages. This level of precision is difficult to achieve with manual packaging methods, where human error can lead to variations in product weight and volume. By using a can packaging machine line, manufacturers can guarantee that each can is filled to the same standard, resulting in a more uniform product.

Furthermore, can packaging machines are equipped with advanced technology that allows for tight seals and secure closures. This is essential for preserving the freshness and shelf life of food products. Improper sealing can lead to contamination and spoilage, which can have serious consequences for both consumers and manufacturers. With a can packaging machine line, manufacturers can rest assured that their products are properly sealed and protected from external factors that could compromise their quality.

In addition to improving product quality, can packaging machines also offer increased efficiency and productivity. These machines are capable of high-speed production, allowing manufacturers to package a large volume of products in a short amount of time. This not only reduces labor costs but also increases output, enabling manufacturers to meet the demands of a growing market. By automating the packaging process, can packaging machines help streamline operations and improve overall efficiency.

Another benefit of using a can packaging machine line is the flexibility it offers in terms of packaging design and customization. These machines can accommodate a variety of can sizes and shapes, allowing manufacturers to package their products in a way that best suits their branding and marketing strategies. Whether it’s a sleek and modern design or a traditional and classic look, can packaging machines can be tailored to meet the specific needs of each manufacturer.

Furthermore, can packaging machines are easy to operate and maintain, making them a cost-effective solution for food manufacturers. With minimal training required, operators can quickly learn how to use these machines effectively, reducing the risk of downtime and production delays. Additionally, can packaging machines are designed to be durable and long-lasting, requiring minimal maintenance and upkeep. This means that manufacturers can rely on these machines to consistently deliver high-quality packaging without the need for frequent repairs or replacements.

Overall, investing in a can packaging machine line can have a significant impact on the quality and consistency of food products. From precision filling and secure sealing to increased efficiency and flexibility, these machines offer a range of benefits that can help manufacturers improve their packaging processes and enhance the overall quality of their products. By incorporating can packaging machines into their operations, food manufacturers can ensure that their products are packaged to the highest standards, meeting the expectations of consumers and maintaining a competitive edge in the market.

Enhanced Food Safety and Hygiene

In the food industry, ensuring the safety and hygiene of products is of utmost importance. One way to achieve this is through the use of can packaging machine lines. These machines offer a range of benefits that can help improve food safety and hygiene standards in food production facilities.

One of the key benefits of can packaging machine lines is the reduction of human contact with the food products. By automating the packaging process, these machines minimize the risk of contamination from human hands. This is particularly important in environments where strict hygiene standards are required, such as in the production of perishable goods.

Furthermore, can packaging machine lines are designed to meet the highest hygiene standards. These machines are made from materials that are easy to clean and sanitize, reducing the risk of bacterial growth and cross-contamination. This is essential for ensuring the safety of food products and preventing the spread of foodborne illnesses.

In addition to improving food safety, can packaging machine lines also offer benefits in terms of efficiency and productivity. These machines are capable of packaging food products at a much faster rate than manual labor, increasing the overall output of the production line. This can help food manufacturers meet the demands of their customers and stay competitive in the market.

Moreover, can packaging machine lines are designed to be versatile and adaptable to different types of food products. Whether it’s canned fruits, vegetables, or meats, these machines can be customized to meet the specific packaging requirements of each product. This flexibility allows food manufacturers to streamline their production processes and reduce waste.

Another advantage of can packaging machine lines is the reduction of packaging errors. These machines are equipped with sensors and automation technology that ensure precise and consistent packaging of food products. This helps to minimize the risk of mislabeling or incorrect packaging, which can lead to costly recalls and damage to a company’s reputation.

Overall, can packaging machine lines offer a range of benefits for food manufacturers looking to improve food safety and hygiene standards. By reducing human contact with food products, meeting high hygiene standards, increasing efficiency and productivity, and minimizing packaging errors, these machines can help food manufacturers produce safe and high-quality products for consumers.

In conclusion, investing in a can packaging machine line can be a wise decision for food manufacturers looking to enhance food safety and hygiene in their production facilities. These machines offer a range of benefits that can help improve the overall quality of food products while also increasing efficiency and productivity. By automating the packaging process and ensuring strict hygiene standards, can packaging machine lines can help food manufacturers meet the demands of their customers and stay competitive in the market.