Table of Contents

Benefits of Using an Automatic Screw Tightening Capping Machine for Glass Pepper Jars

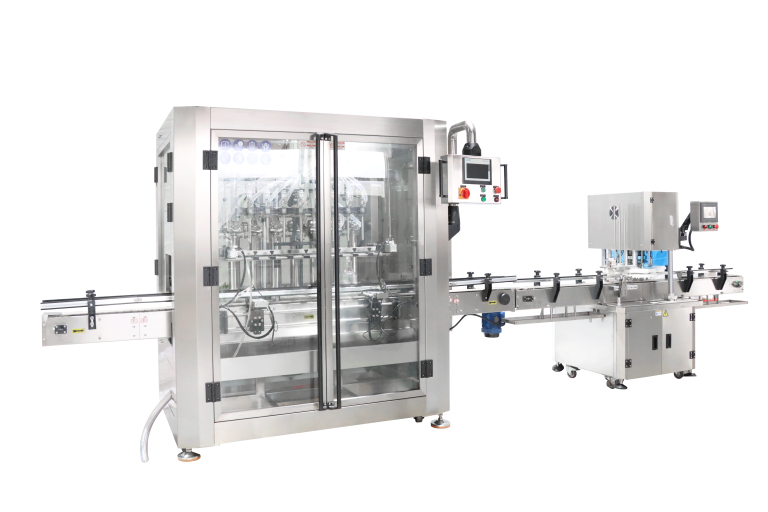

Glass pepper jars are a popular choice for packaging spices due to their durability and ability to preserve the freshness of the contents. However, sealing these jars properly can be a time-consuming and labor-intensive process. This is where an automatic screw tightening capping machine comes in handy.

One of the main benefits of using an automatic screw tightening capping machine for glass pepper jars is the efficiency it brings to the packaging process. With traditional manual capping methods, workers have to tighten each screw cap individually, which can be a slow and tedious task. In contrast, an automatic capping machine can cap multiple jars simultaneously, significantly reducing the time and effort required for packaging.

Not only does an automatic capping machine save time, but it also ensures consistency in the sealing process. Manual capping can lead to variations in the tightness of the screw caps, which can affect the shelf life of the product. With an automatic capping machine, each jar is sealed with the same level of precision, ensuring that the contents are properly preserved.

In addition to efficiency and consistency, an automatic screw tightening capping machine also helps improve the overall quality of the packaging. The machine is designed to apply the right amount of torque to each screw cap, preventing over-tightening or under-tightening. This not only ensures that the jars are properly sealed but also reduces the risk of damage to the jars or the contents inside.

Another benefit of using an automatic capping machine for glass pepper jars is the reduction in labor costs. By automating the capping process, companies can free up their employees to focus on other tasks, increasing productivity and efficiency in the packaging line. This can lead to cost savings in the long run, as companies can produce more jars in less time with fewer resources.

Furthermore, an automatic capping machine can help improve the overall safety of the packaging process. Manual capping can be a repetitive task that can lead to strain or injury for workers. By automating this process, companies can reduce the risk of workplace injuries and create a safer working environment for their employees.

Overall, the benefits of using an automatic screw tightening capping machine for glass pepper jars are clear. From increased efficiency and consistency to improved quality and safety, this machine offers a range of advantages for companies looking to streamline their packaging process. By investing in an automatic capping machine, companies can save time, reduce labor costs, and ensure that their products are properly sealed and preserved.

How to Choose the Right Automatic Screw Tightening Capping Machine for Glass Pepper Jars

When it comes to packaging glass pepper jars, ensuring that the lids are securely tightened is crucial to maintaining product freshness and preventing leaks. This is where an automatic screw tightening capping machine comes in handy. These machines are designed to efficiently and accurately tighten the caps on glass pepper jars, ensuring a tight seal every time. However, with so many options available on the market, choosing the right automatic screw tightening capping machine for your specific needs can be a daunting task.

One of the first things to consider when choosing an automatic screw tightening capping machine is the size and shape of your glass pepper jars. Different machines are designed to accommodate different jar sizes and shapes, so it’s important to choose a machine that can handle the specific dimensions of your jars. Additionally, consider the speed at which you need the machine to operate. Some machines are capable of tightening hundreds of jars per minute, while others may have a slower output. Determine your production needs and choose a machine that can keep up with your demand.

Another important factor to consider is the level of automation you require. Some automatic screw tightening capping machines are fully automated, requiring minimal human intervention, while others may require more manual input. Consider the level of automation that best suits your production process and choose a machine accordingly. Additionally, consider the ease of use and maintenance of the machine. Look for a machine that is user-friendly and easy to clean and maintain to ensure smooth operation and longevity.

When choosing an automatic screw tightening capping machine, it’s also important to consider the quality and reliability of the machine. Look for a machine from a reputable manufacturer with a track record of producing high-quality equipment. Read reviews and testimonials from other users to get an idea of the machine’s performance and reliability. Additionally, consider the warranty and after-sales support offered by the manufacturer. A reliable machine with good customer support can save you time and money in the long run.

Cost is another important factor to consider when choosing an automatic screw tightening capping machine. While it’s important to stay within budget, it’s also important to consider the long-term costs associated with the machine. Look for a machine that offers a good balance of quality and affordability, and consider the return on investment over time. Additionally, consider any additional features or customization options that may be beneficial for your specific needs.

In conclusion, choosing the right automatic screw tightening capping machine for glass pepper jars requires careful consideration of several factors. Consider the size and shape of your jars, the speed and level of automation required, the quality and reliability of the machine, and the cost and long-term value. By taking these factors into account and doing thorough research, you can choose a machine that meets your production needs and helps you achieve efficient and consistent results.